BOOST CONVERTER DESIGN FOR 20KW WIND TURBINE GENERATOR

S. Jiao, D. Patterson and S. Camilleri

NT Center for Energy Research

Northern Territory University

Darwin, NT0909

Email: shuli.jiao@ntu.edu.au

Tel: 08-8946 6386 Fax: 08-8946 6993

Abstract

This paper presents the converter design for a 20kW wind turbine generator. The converter

consists of a phase controlled rectifier and a DC/DC boost converter. The rectifier makes the

generator AC voltage match the DC voltage while the boost converter keeps the DC voltage

constant. The generator's synchronous inductance acts as an AC inductor of boost converter so no

extra DC inductor is required. This converter is designed to be efficient and cheap. However, this

converter does result in higher power loss in the generator due to its non-sinusoidal phase current,

especially when the firing angle is not equal to 0.

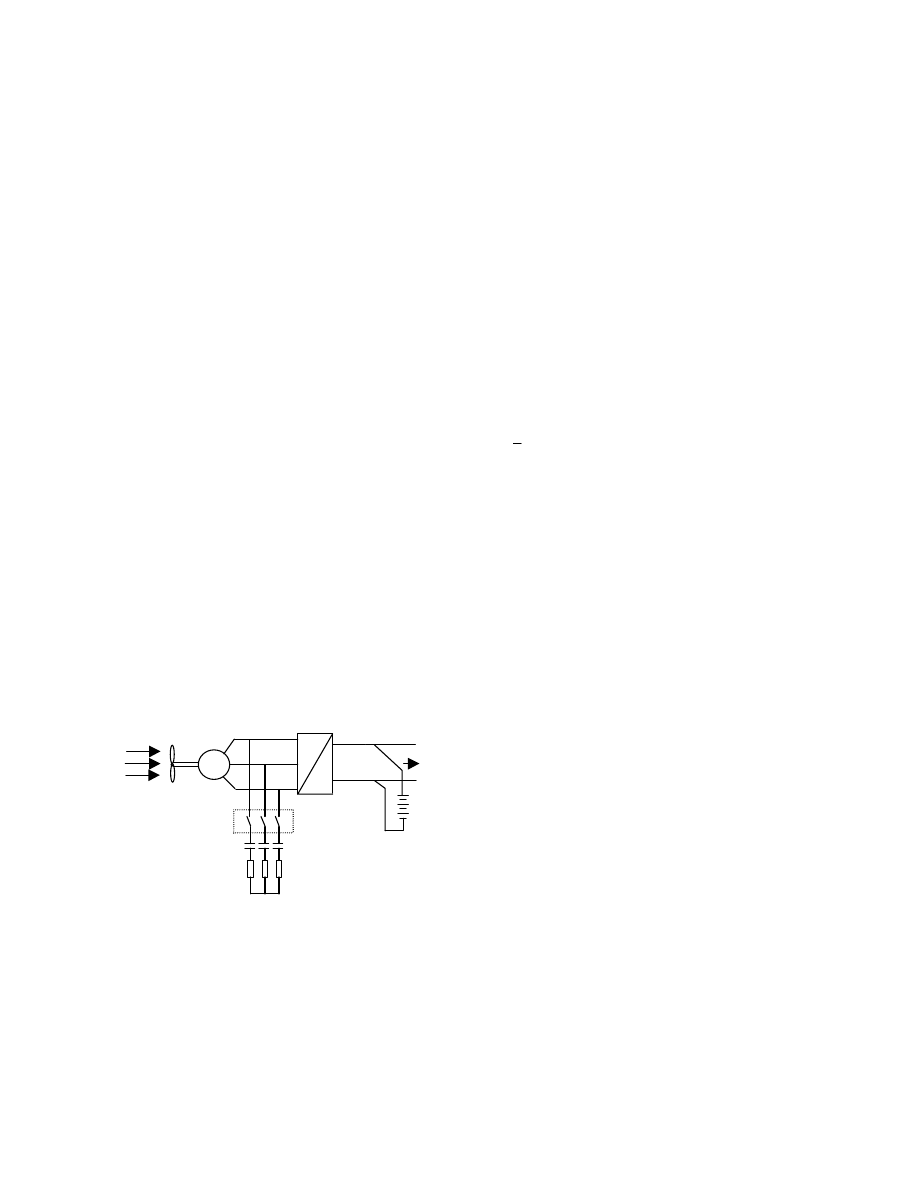

1. POWER FLOW DIAGRAM

The power flow diagram for the 20kW wind generator

system is shown in Figure 1. The wind drives the wind

turbine, which is connected to the wind generator,

therefore the wind energy is converted to electrical

energy. The generator's AC voltage is converted to

DC voltage through an AC/DC converter. The DC

output voltage is fed to the load and battery bank. The

voltage should stay constant for various wind speeds.

When the wind speed is too high, i.e., the generator

produces too much power and voltage, the dump load

is connected through the switches. Also, the blade

pitch control can be employed in an emergency. When

the wind speed is low, the generator together with the

battery bank can provide sufficient energy to the load.

Figure 1. Power Flow Diagram of Wind Turbine System

In Figure 1, the battery bank is composed of 120

series connected Pd-Acid batteries, each at 2.35V and

all together at 282V. The rated speed is 10.5m/s wind

speed, 211rpm rotor speed. The wind turbine's cut-in

and cut-out wind speeds are 3m/s and 25m/s

respectively, corresponding to 60rpm and 266rpm

rotor speed. The wind energy P versus the wind

velocity v is expressed as:

3

2

1

v

AC

P

p

ρ

=

(1)

Where:

ρ

is the air density; A is the area of the air

interrupted by the wind turbine and C

p

is the

coefficient of the power of the wind turbine.

2. WIND GENERATOR

The wind generator is a three phase brushless

permanent magnet machine so the airgap flux

Φ can

be assumed to be constant. The back emf E

0

is

proportional to the rotor speed n, i.e.,

n

C

E

e

Φ

=

0

(2)

Where, C

e

is the voltage coefficient. The above

equation indicates how the wind energy is converted

to electrical energy. The generator outputs 20kW into

a resistive load at 211rpm, and up to 40kW with a

capacitive load at 266rpm for 3s or longer and

depending on its temperature rise before the overload.

The main features of the wind generator are shown in

appendix.

3. CONVERTER DESIGN

In order to make the generator's AC voltage match the

DC voltage, there are a few options. Firstly, the stator

of the generator is delta connected while the AC/DC

converter is composed of a three phase uncontrolled

rectifier and a boost converter [1]. Considering that

the synchronous inductance of the generator is large

enough to act as an AC inductor, therefore no extra

DC inductor with high frequency operation is needed

in the boost converter. The controller is cheap with

medium power loss. However, the large third

harmonics in the generator's phase voltage makes

delta connection impossible. Secondly, the stator of

G

AC

DC

Wind

BLDC

PM

Generator

Dump

Load

Switches

Load

Battery

the generator is star connected while the AC/DC

converter is composed of a three phase uncontrolled

rectifier and a buck-boost converter. The buck-boost

converter can step the DC voltage up and down,

however the main difficulty is that an extra DC

inductor with high frequency operation is essential

and the power loss of buck-boost converter is high as

well. The converter is more expensive with higher and

power loss comparing to the first converter.

Another solution is that the stator of the generator

remains star connected, while the converter employs a

phase-controlled rectifier and a boost converter. The

rectifier is used to match the generator's AC voltage

and the DC voltage while the boost converter keeps

the DC voltage constant. The rectifier and the boost

converter are shown in Figure 2 and Figure 3

respectively.

Figure 2. Phase Controlled Rectifier

Figure 3. DC/DC Boost Converter

3.1 Phase-Controlled Rectifier

In Figure 2, the rectifier consists of six SCRs and a

free-wheeling diode that provides an additional path

for the load current and prevents negative values of

DC voltage from occurring. Generally, the rectifier

has three operation modes: (1) normal mode, for

example when SCR1 and SCR5 conduct. The rectifier

is likely to run at this mode considering the wind

generator's low speed operation. (2) commutation

mode, for example, when SCR1, SCR5 and SCR6

conduct. This is transition period between two

different normal modes. The commutation angle is not

negligible for this generator due to its large

synchronous reactance. (3) free-wheeling mode. This

happens when

α

>60

°

.

The advantage of a phase-controlled rectifier is that

the energy can not flow from DC side to the generator

while DC voltage is positive. However, it has some

drawbacks:

- the generator operates under unsymmetrical

load, especially at low speed.

- the phase current contains high harmonics that

increase the power loss and decrease the

efficiency.

At this stage, we neglect the commutation angle.

When the generator operates under rated speed

(n=211rpm) and rated power (P=20kW), the average

DC voltage V

avg

and its ripple are given by

U

V

V

line

avg

∆

−

α

π

=

2

cos

2

3

(3)

Here,

α

is the firing angle of SCRs. 2

∆

U is the

potential drop of the SCR and diode.

Initially, we assume

α

=0

°

, Under rated condition,

V

avg

=305.33V while 2

∆

U=3.2V.

V

d

V

V

V

avg

line

ripple

28

.

13

)

sin

2

(

2

6

3

/

2

3

/

2

=

θ

−

θ

×

π

=

∫

π

π

The average current depends on the load. Assume it is

20kW resistive load, the average and ripple current

are:

A

I

avg

50

.

65

=

,

A

I

ripple

84

.

2

=

. From the current

ripple, we can select the DC capacitor C

B

. Also, from

the maximum voltage and RMS current across the

SCR when the generator operates with 40kW

capacitive load, we can select the proper SCRs and

diode.

Assuming the load is resistive, the rectifier's DC

current and other quantities can be estimated by the

following procedures:

(1) find power P from equation (1)

(2) find fundamental frequency f from rotor speed n

(3) find back emf E

0

from equation (2)

(4) estimate the phase current from the DC current as

DC

line

DC

line

line

phase

I

V

I

V

I

I

π

=

π

=

=

6

3

)

/

2

3

(

(4)

(5) from the generator's vector diagram,

L

S

D

C

y

z

x

+

_

V

1

I

1

i

z

i

y

+

_

_

+

V

2

I

2

v

xz

C

1

SCR1

SCR4

SCR6

SCR5

SCR2

SCR3

V

a

V

b

V

c

+

_

V

I

C

B

D

]

)

2

(

[

)

6

(

3

2

)

6

3

(

]

)

2

(

[

)

6

(

]

6

3

[

]

6

[

2

)

6

3

(

)

2

(

)

(

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

0

a

DC

DC

a

DC

DC

DC

DC

a

phase

phase

phase

fL

R

I

RP

V

fL

R

I

V

R

I

V

fL

I

R

I

V

E

π

+

π

+

+

π

=

π

+

π

+

π

×

π

×

+

π

=

π

+

+

=

hence,

]}

)

2

(

[

)

6

(

3

2

{

)

6

3

(

2

2

2

2

2

0

2

2

a

DC

DC

fL

R

I

RP

E

V

π

+

π

−

−

π

=

(5)

(6) put equation (3) (neglect diode voltage drop

3.2V), (4), (5) into DC power equation i.e.,

2

2

2

DC

DC

I

V

P

=

. Solving this second order

algebraic equation, we can get the DC current,

]

)

2

(

[

216

.

1

]

)

2

(

[

4445

.

0

)

3

2

(

3

2

2

2

2

2

2

2

2

0

2

0

a

a

DC

fL

R

fL

R

P

RP

E

RP

E

I

π

+

π

+

−

−

−

−

=

(6)

For instance, when n=211rpm, E

0

=196.55V, P=20kW,

R=0.2873

Ω

, L

a

=6.514mH, f=63.3Hz, from the above

equation, I

DC

=63.26A, there is 3.3% error due to the

above assumptions such as neglecting of commutation

angle, voltage drop of diode,

α

=0

°

at this stage etc.

Here we can put a correcting factor k=1.033 in

equation (6) to reduce the error.

(7) find other quantities such as V

DC

etc. Here, V

DC

may be greater than V

2

=282V, e.g., under rated

condition. Then we need adjust the firing angle to

limit V

DC

to 282V. It follows in next step.

(8) if V

DC

≤

282V,

α

=0

°

if V

DC

>282V, find

α

from Equation (3), i.e.,

(neglecting 2

∆

U)

)

V

282

(

cos

DC

1

−

=

α

(15)

in this case, V

DC(new)

=282V.

(9) correct the I

DC

by I

DC(new)

=P/282 if V

DC

is greater

than 282V in order to output the same power.

Note that, it is assume that the fundamental

frequency of line voltage and current stay the

same as before because the power output does not

change. Therefore, we need not correct the AC

values.

For example, under the rated operating condition,

V

DC

=305.33V I

DC

=65.5A for diode rectifier, while

α=22

.54

°

, V

DC

=282V, I

DC

=70.93A for the phase-

controlled rectifier.

The switching power losses are very small for SCRs

due to low frequency operation, hence the overall

power loss of the rectifier P

B

can be taken as its

conduction loss expressed by

)

(

)

(

2

6

)

3

/

(

AV

F

TM

AV

F

TM

B

I

V

I

V

P

=

×

=

(7)

Where, V

TM

is the on-state voltage and I

F(AV)

is the

average forward current. The total loss of rectifier

under rated condition is 227W.

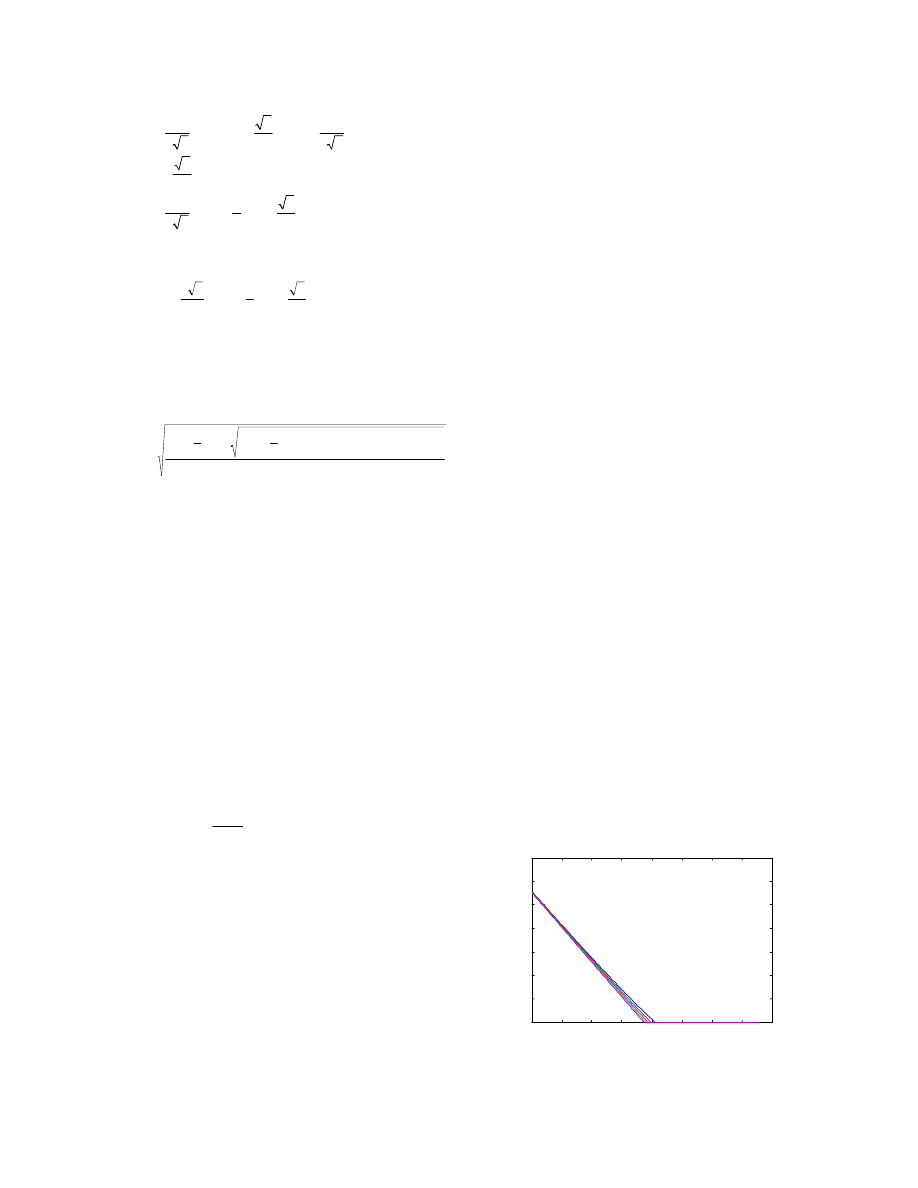

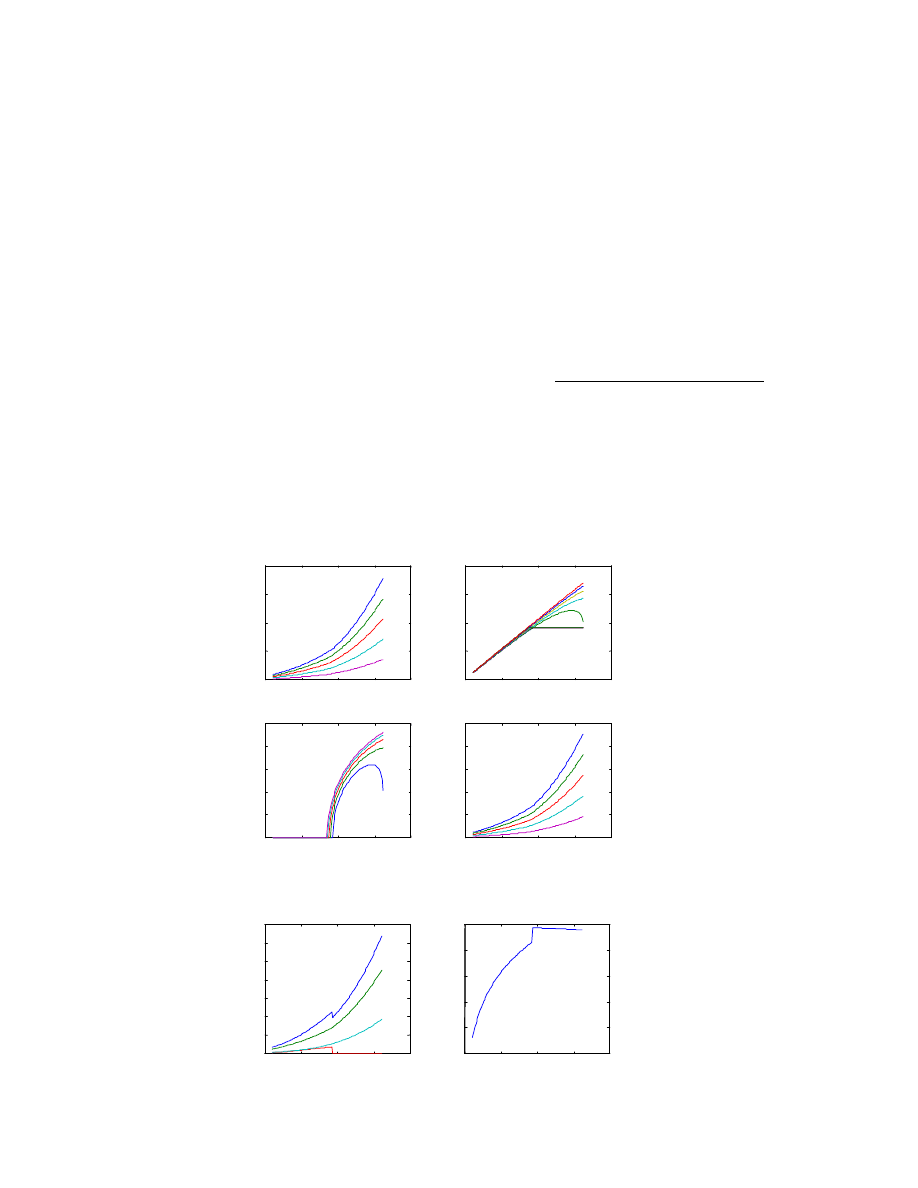

Figure 4 shows the rectifier's performance versus the

rotor speed with different loads, i.e., 1.0, 0.8, 0.6, 0.4,

0.2 rated load. V

1

represents the DC voltage fed to

DC/DC converter whilst V

DC

for the DC voltage in

case of diode rectifier, i.e.,

α

=0

°

. At rated load, the

rectifier takes effect for the speeds over 142rpm,

below this speed, the DC/DC boost converter is

needed to boost the DC voltage up.

3.2 DC/DC Boost Converter

The DC/DC converter is chosen to be a direct boost

converter as shown in Figure 3. Initially, it is assumed

that there is no power loss in the converter. The

voltage and current relationships between the primary

and secondary sides are shown in Equation (8) and (9)

respectively.

D

V

V

−

=

1

/

2

1

(8)

D

I

I

−

=

1

/

1

2

(9)

Here, D stands for the duty ratio, which is defined as

the ratio between the conduction time of the switch

TR and the duty period. When the generator operates

under rated condition, V

1

=V

2

=282V, I

1

=I

2

=70.92A,

hence D=0. The duty ratio versus rotor speed under

different loads is shown in Figure 5.

Figure 5. Duty Ratio versus Rotor Speed

with 1.0, 0.8, 0.6, 0.2 rated Loads

60

80

100

120

140

160

180

200

220

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

D

n(rpm)

0.2…1.0

From Figure 4 and Figure 5, it can be seen that the

converter is structured as a rectifier and a boost

converter. When the line voltage of generator is high,

the rectifier takes effect while D=0; on the other hand,

when the voltage of generator is low, the boost

converter takes effect while

α

=0

°

.

The ripple in V

2

should not be too high as the

secondary side of the boost converter is connected to

the battery bank. The primary side of the boost

converter is connected to the turbine generator via the

rectifier. The ripple in I

1,

which introduces power loss

in the generator, could be high, e.g., if the current

ripple is 10% of the DC current, the copper loss is 1%

of the main copper loss, which is only a small part of

the power loss. Note that the capacitor C

B

of the

rectifier takes the effect of C

1

. The primary voltage is

assumed to contain no harmonics after the capacitor

C

B

, therefore, the values of L and C should be

2

2

)

1

(

v

T

D

I

C

∆

−

≥

(10)

1

1

)

1

(

i

T

D

V

L

∆

−

≥

(11)

Where,

∆v

2

,

∆i

1

are voltage and current ripples

respectively. Assuming f

s

=20KHz, T=50

µ

s. Let

%

5

/

2

2

≤

∆

V

v

and

%

10

/

1

1

≤

∆

I

i

, we get C>155.4uF,

L>1.229mH.

The generator's phase inductor can be used as AC

inductor L while a DC inductor is not necessary [3-5].

There are two phases conducting at each time, so

L=2L

phase

=2

×

(2/3)

×

6.514 =8.685mH, which is larger

than required value.

In Figure 3, it is assumed that all the DC components

of current across the diode pass to the secondary side

of boost converter that forms the current I

2

while the

AC component passes to the capacitor C, the current

ripple across C in RMS value is estimated by

1

2

1

2

1

)

1

(

]

)

1

[(

)

1

(

)

(

I

D

D

D

I

D

D

DI

I

C

×

−

=

−

+

−

=

(12)

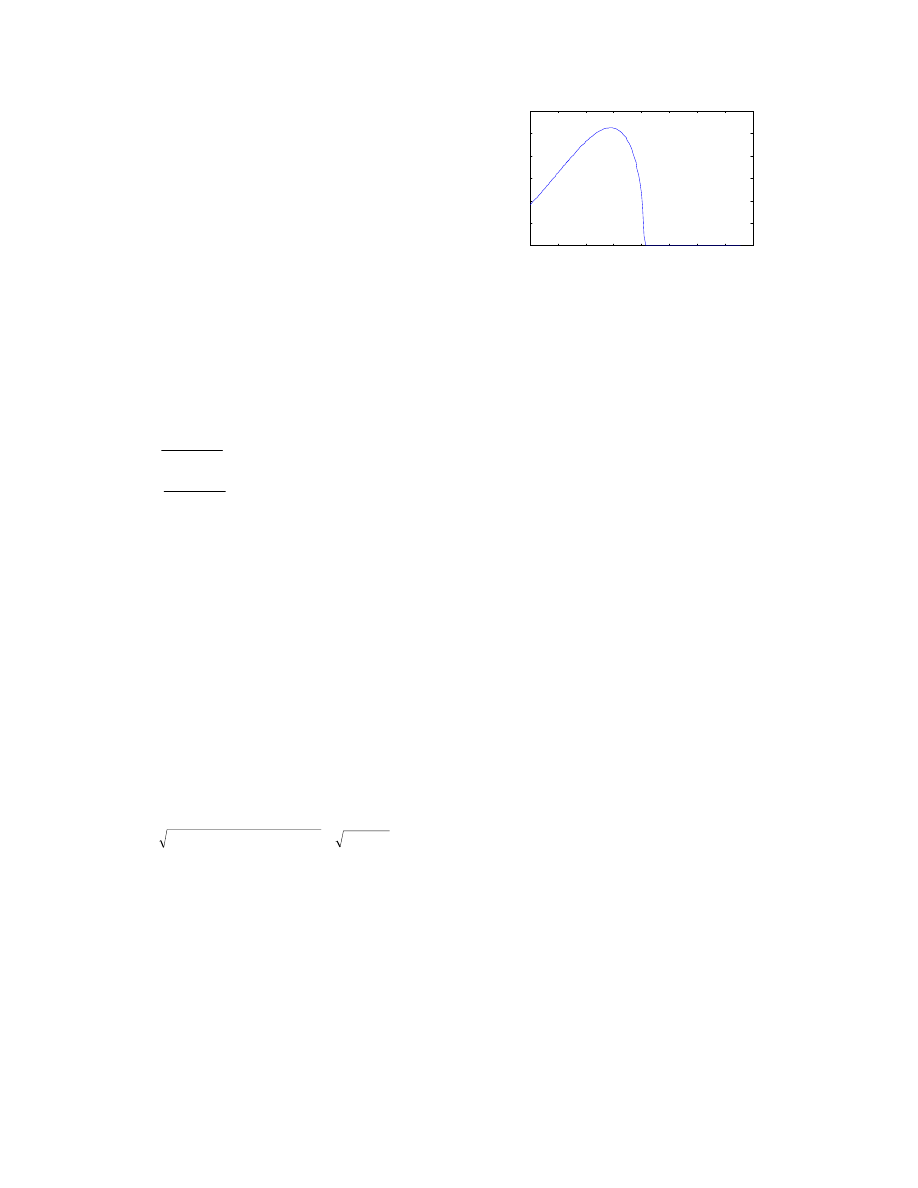

The current ripple in capacitor I

C

versus rotor speed

with full load given by Equation (1) is shown in

Figure 6. Its maximum current is I

Cmax

=5.26A which

occurs at n=118rpm with the power of 1768W. At this

stage, we can choose the proper capacitor.

The power losses of the boost converter are mainly

from the diode and switch (MOSFET). For the diode,

the conduction loss is dominant which is expressed by

2

)

(

)

(

0

RMS

F

t

AV

F

t

D

I

r

I

V

P

+

=

(12)

Figure 6. The Current Ripple in Capacitor C

Where, I

F(AV)

=(1-D)I

1

; I

F(RMS)

=(1-D)

0.5

I

1

; V

t0

is the

threshold voltage and r

T

is the slope resistance.

On the other hand, the power loss of MOSFET P

M

are

determined by its conduction loss P

M1

, off switching

loss P

M2

and on switching loss P

M3

. They are

)

(

2

1

1

on

DS

M

R

DI

P

=

(13)

f

s

M

t

f

I

V

P

1

1

2

=

(14)

r

s

M

t

f

I

V

P

1

1

3

=

(15)

Where, R

DS(on)

is the drain-source on-state resistance; t

f

and t

r

are current fall and rise time respectively.

The total losses of the boost converter are the

summation of the losses of the rectifier and the boost

converter. The total power losses and efficiencies can

be seen from Figure 7. It can be seen that The

maximum power loss is 320W when n=211rpm with

rated load. The maximum efficiency is 98.44% when

n=143rpm with 6226W output while the minimum

efficiency is 96.31% when n=60rpm with 459.87W.

4. CONCLUSION

The rectifier and the boost converter are designed for a

20kW wind generator. At various wind speeds, all the

quantities of the system including AC, DC voltages

and currents, duty ratio, power loss and efficiency can

be estimated through mathematical methods. The

generator's synchronous inductance is large enough to

act as the AC inductor of the boost converter,

therefore no extra DC inductor is required.

When the line voltage is too high, phase-controlled

rectifier is employed to limit the primary DC voltage

hence the duty ratio of boost converter is set to 0. In

this case, the power loss mainly originates from the

rectifier. On the other hand, when the line voltage is

low, set the firing angle of rectifier to 0 and the

primary voltage can be boosted to that of battery bank

through the boost converter. In this case, the power

loss of boost converter is still very low due to the low

current. Therefore, the converter is designed to be

very efficient.

60

80

100

120

140

160

180

200

220

0

1

2

3

4

5

6

IC

(A

)

n(rpm)

However, this converter does result in higher power

loss in the generator due to its non-sinusoidal phase

current, especially when the firing angle is not equal

to 0. A six switch voltage source converter with

closed loop current control can provide sinusoidal

current, unity power factor but it is more expensive.

The latter converter is beyond this paper and will be

introduced later.

5. ACKNOWLEGEMENT

The authors would like to thank Australian CRC for

Renewable Energy Ltd (ACRE) for the financial

support and technical support from ACRE and UTS.

6. REFERENCES

[1] Jiao, S. and Patterson, D., “Converter Design for

20kW Wind Turbine Generator with Delta

Connection”, Internal Report of ACRE, April,

1999.

[2] Jiao, S. and Patterson, D., “Buck-Boost Converter

Design for 20kW Wind Turbine Generator with

Star Connection”, Internal Report of ACRE, May,

1999.

[3] Salmon, J. C., “Reliable 3-phase PWM Boost

Rectifier Employing a Staked Dual Boost

Converter Subtopology”, IEEE Trans. on Industry

Applications, Vol. 32, No. 3, May/June 1996,

PP542-551.

[4] Salmon, J. C., “Techniques for Minimizing the

Input Current Distortion of Current-Controlled

Single Phase Boost Rectifiers”, IEEE Trans. on

Power Electronics, Vol. 8, No. 4, October 1993,

PP509-520.

[5] Salmon, J. C., “Circuit Topologies for Single-

Phase Voltage-Doubler Boost Rectifiers”, ibid,

PP542-551.

[6] Fisher, F. J., “Power Electronics”, PWS-Kent

Publishing Company, 1991.

APPENDIX: Features of 20kW Wind Generator

Rated Power Output:

20kW

Rated Speed:

211rpm

Stator Winding Connection:

star

Number of Rotor Poles:

36

Stator Phase Resistor:

0.2873

Ω

Synchronous inductance:

6.514mH

Rated Phase Current:

50.6A

Rated Phase Voltage:

131.9V

Figure 4. Performance of Phase-controlled Rectifier under 1.0, 0.8, 0.6, 0.4, 0.2 Rated Load

Figure 7. Total Power Loss and Efficiency versus Rotor Speed

50

100

150

200

250

0

20

40

60

80

ID

C

(A

)

n(rpm)

50

100

150

200

250

100

200

300

400

500

V

1

,V

D

C

(V

)

n(rpm)

50

100

150

200

250

0

10

20

30

40

50

a

(d

e

g

re

e

)

n(rpm)

50

100

150

200

250

0

50

100

150

200

250

P

B

(w

)

n(rpm)

1.0

…

0.2

0.2

…

1.0

0.2

…

1.0

1.0

…

0.2

50

100

150

200

250

0

50

100

150

200

250

300

350

,P

(t

o

ta

l)

,P

B

,P

M

,P

D

(W

)

n(rpm)

50

100

150

200

250

96

96.5

97

97.5

98

98.5

E

i(

%

)

n(rpm)

P

total

P

B

P

D

P

M

Document Outline

- Contents

Wyszukiwarka

Podobne podstrony:

CEI 61400 22 Wind turbine generator systems Required Design Documentation

CEI 61400 22 Wind turbine generator systems Required Design Documentation

DC DC Converter for EWB Wind Turbine Project review

[2006] Application of Magnetic Energy Recovery Switch (MERS) to Improve Output Power of Wind Turbine

20060028025 Wind Turbine Generator System

(WinD Power) Dynamic Modeling of Ge 1 5 And 3 6 Wind Turbine Generator {}[2003}

IEC 61400 11 Wind turbine generator systems en

20050253396 Variable Speed Wind Turbine Generator

ANALYSIS OF CONTROL STRATEGIES OF A FULL CONVERTER IN A DIRECT DRIVE WIND TURBINE

Wind Turbine Generator Rotor Construction (BackHome Magazine)(2s)

Development Of A Single Phase Inverter For Small Wind Turbine

The Material Selection for Typical Wind Turbine Blades 2006

20060028025 Wind Turbine Generator System

DIN 61400 21 (2002) [Wind turbine generator systems] [Part 21 Measurement and assessment of power qu

[Engineering] Electrical Power and Energy Systems 1999 21 Dynamics Of Diesel And Wind Turbine Gene

[2006] Application of Magnetic Energy Recovery Switch (MERS) to Improve Output Power of Wind Turbine

więcej podobnych podstron