Drying kinetics and rehydration characteristics

of microwave-vacuum and convective hot-air dried mushrooms

S.K. Giri, Suresh Prasad

*

Department of Agricultural and Food Engineering, Post Harvest Technology Centre, Indian Institute of Technology, Kharagpur 721 302, India

Received 5 March 2005; accepted 27 October 2005

Available online 20 December 2005

Abstract

Microwave-vacuum dehydration characteristics of button mushroom (Agaricus bisporus) were evaluated in a commercially available

microwave oven (0–600 W) modified to a drying system by incorporating a vacuum chamber in the cavity. The effect of drying param-

eters, namely microwave power, system pressure and product thickness on the drying kinetics and rehydration characteristics were inves-

tigated. The drying system was operated in the microwave power range of 115–285 W, pressure range of 6.5–23.5 kPa having mushroom

slices of 6–14 mm thickness. Convective air drying at different air temperatures (50, 60 and 70

C) was performed to compare the drying

rate and rehydration properties of microwave-vacuum drying with conventional method. Microwave-vacuum drying resulted in 70–90%

decrease in the drying time and the dried products had better rehydration characteristics as compared to convective air drying. The rate

constants of the exponential and Page’s model for thin layer drying were established by regression analysis of the experimental data

which were found to be affected mainly by the microwave power level followed by sample thickness while system pressure had a little

effect on the drying rate. Rehydration ratio was significantly affected by the system pressure. Empirical models are also developed for

estimating the drying rate constant and rehydration ratio as a function of the microwave-vacuum drying process parameters.

2005 Elsevier Ltd. All rights reserved.

Keywords: Microwave-vacuum drying; Button mushroom; Drying rate; Scanning electron microscopy; Rehydration ratio

1. Introduction

Mushrooms are edible fungi of commercial importance

and their cultivation and consumption has increased sub-

stantially due to their nutritional value, delicacy and flavor.

The button mushroom (Agaricus bisporus) is the most

widely cultivated and consumed mushroom throughout

the world and it contributes about 40% of the total world

production of mushroom. Mushrooms are extremely per-

ishable and the shelf life of fresh mushroom is only about

24 h at ambient conditions. Various physiological and mor-

phological changes occur after harvest, which make these

mushrooms unacceptable for consumption. Hence, they

should be consumed or processed promptly after harvest

and for this reason the mushrooms are traded mostly in

processed form in the world market.

Dehydration is one of the important preservation meth-

ods employed for storage of mushroom and dehydrated

mushrooms are valuable ingredients in a variety of sauces

and soups. As mushrooms are very sensitive to tempera-

ture, choosing the right drying method can be the key for

a successful operation. Mushroom growers continue to

dry mushroom under sun, which yields unhygienic and

poor quality product. The conventional hot-air drying of

mushrooms normally involves thermal and/or chemical

pretreatment and drying at temperature maintained

between 50 and 70

C. Due to long drying time and over-

heating of surface during hot-air drying, the problems of

darkening in colour, loss in flavour and decrease in rehy-

dration ability occur. Freeze drying produces a high quality

product, but being an expensive process, its application for

mushroom drying is limited. Vacuum drying is another

0260-8774/$ - see front matter

2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.jfoodeng.2005.10.021

*

Corresponding author. Fax: +91 3222 282288.

E-mail addresses:

(S.K. Giri),

(S. Prasad).

www.elsevier.com/locate/jfoodeng

Journal of Food Engineering 78 (2007) 512–521

alternative method and is especially suitable for products

that are prone to heat damage such as fruits and vegeta-

bles. However, in vacuum process requiring heat, transfer

of heat energy to the workload becomes difficult, as con-

vection is ineffective at low pressure. Most conventional

vacuum dryers rely on conduction heat transfer from hot

plates, which is slow, difficult to control and requires a

large surface area and therefore, conventional vacuum dry-

ing has high operating and installation cost (

). The desire to prevent significant quality loss

and to achieve fast and effective dehydration has resulted

in increasing use of microwave heating for food drying.

Microwave drying is rapid, more uniform and energy

efficient compared to conventional hot-air drying. In recent

years, Microwave-vacuum drying (MVD) has been investi-

gated as a potential method for obtaining high quality

dried food products, including fruits, vegetables and

grains. Microwave-vacuum drying combines the advanta-

ges of both microwave heating and vacuum drying. The

low temperature and fast mass transfer conferred by vac-

uum combined with rapid energy transfer by microwave

heating generates very rapid, low temperature drying and

thus it has the potential to improve energy efficiency and

product quality. Some fruits and grains have been success-

fully dried by microwave-vacuum drying techniques (

). Despite those investigations, there is

scanty information available either in terms of the drying

kinetics or quality of button mushroom undergoing micro-

wave-vacuum drying technique.

The drying kinetics is often used to describe the combined

macroscopic and microscopic mechanisms of heat and mass

transfer during drying, and it is affected by drying condi-

tions, types of dryer and characteristics of materials to be

dried. Since on-line measurement of temperature and mois-

ture is difficult and time-consuming for microwave assisted

heating and drying, the drying kinetics models are essential

for equipment design, process optimization and product

quality improvement. The effect of vacuum in microwave

drying operation is system specific, and for successful design

and operation of an industrial microwave-vacuum drying

system, knowledge of the drying characteristics of the mate-

rial to be dried under a range of condition is vital (

). The aim of the present work

was to investigate microwave-vacuum drying characteristics

of button mushroom slices and to compare with convective

hot-air drying in respect to drying kinetics, rehydration qual-

ities and micro structural changes of the dried products.

2. Material and methods

2.1. Materials

Fresh button mushrooms (A. bisporus) were obtained

from market and kept in cold storage at 4–5

C. Prior to

dehydration, mushrooms were thoroughly washed to

remove the dirt and graded by size to eliminate the varia-

tions in respect to exposed surface area. Slices of desired

thickness were obtained by carefully cutting mushrooms

vertically with a vegetable slicer and the slices from middle

portions with characteristics mushroom shape were used

for drying experiments without any pretreatments. They

were immediately weighed and placed into the dryer. Mois-

ture content of the samples was determined in a vacuum

oven at 70

C for 14–16 h (

). The initial mois-

ture content of the slices was ranged from 92% to 93%

(w.b.).

2.2. Drying

2.2.1. Hot-air drying

The mushroom slices were hot-air dried at air tempera-

ture of 50, 60 and 70

C in a cross-flow type dryer with air

flow rates of 1.5 m/s. Air was heated electrically before

entering the heater. Slices were spread in a single layer on

the tray. During air drying, weight and temperature of

the sample were recorded at regular interval of times.

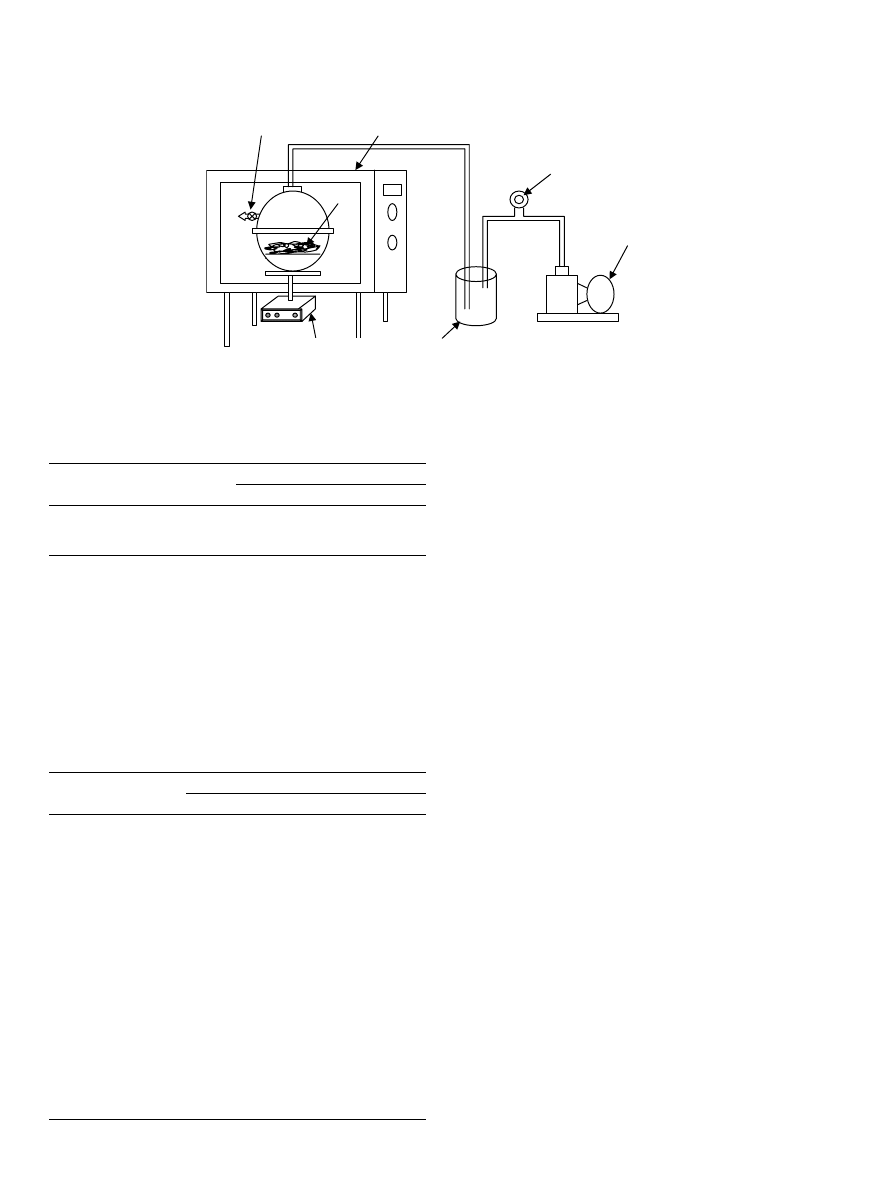

2.2.2. Microwave-vacuum drying

The experimental setup used for the microwave-vacuum

drying of the samples is depicted in

, which consists

of a microwave oven (IFB, model electron) of rated capac-

ity of 600 W at 2.45 GHz. The oven is modified to give

variable power output (from 0 to 600 W) by incorporating

a 230 V AC variac in the circuit (

A glass container containing the material to be dried was

placed inside the microwave cavity and a vacuum pump

was connected to the container for maintaining the desired

levels of vacuum inside it. Vacuum in the container was

monitored by using a vacuum gauge and a pressure regu-

lating valve to maintain the pressure at desirable levels. An

air tight condenser was also used in the vacuum line for

condensing the water vapour released from the samples.

About 100 g of sliced mushrooms were taken for each dry-

ing experiments in the microwave-vacuum dryer at differ-

ent microwave power and pressure levels. The sample

remained in the container for a specified time interval

while drying took place. The weight of the sample was

recorded at every 5 min intervals by switching off the

microwave oven and after releasing the vacuum, which

took about 40 s for each observation. The samples were

dried till the moisture content was reduced to 6–6.5%

(w.b.).

The variables chosen for microwave-vacuum drying

experiments were microwave power (Q), system pressure

(P) and thickness of the slices (T). Response surface

methodology was used to determine the relative contribu-

tions of the above three variables to the drying character-

istics and rehydration ratio. Twenty experiments were

performed according to a central composite rotatable

design with the three variables and with five levels of each

variable. The maximum and minimum variable levels

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

513

were selected on the basis of preliminary drying experi-

ments.

gives the levels of variables in coded

and actual levels and

shows the combination of

variable levels used in the central composite design.

Experiments were randomized in order to minimize the

effects

of

unexplained

variability

in

the

observed

responses due to extraneous factors. The center point in

the design was repeated six times to calculate the repro-

ducibility of the method.

2.3. Modeling drying data

Various transport properties like moisture and thermal

diffusivity and mass and heat transfer coefficients, describe

completely the drying kinetics, although in the literature

sometimes the drying rate constant is used as their combina-

tion and as a trial for standardizing a process description

independently from the controlling mechanism (

). The exponential model, Eq.

and empirical Page’s

model, Eq.

, have been used to describe the drying kinet-

ics of various agricultural materials in convective and

microwave-convective drying (

2001; Pravanjan, Ramaswamy, & Raghavan, 1995; Sharma

& Prasad, 2001

). Both the models were tested for their

validity to mushroom under microwave-vacuum drying:

MR

¼ expðKtÞ;

ð1Þ

MR

¼ expðkt

n

Þ;

ð2Þ

where MR = moisture ratio = (M

M

e

)/(M

0

M

e

); M =

moisture content (kg water/kg dry matter) at time t;

M

e

= equilibrium moisture content (kg water/kg dry mat-

ter); M

0

= initial moisture content (kg water/kg dry mat-

ter) at time = 0; K = drying rate constant (min

1

); k and

n are the parameters of Page’s model; and t = drying time

in min.

The equilibrium moisture content during microwave-

vacuum drying is considered zero, due to vacuum condi-

tions of the process (

Kiranoudis, Tsami, & Maroulis,

). The parameters K, k and n of the above equations

were evaluated through non-linear regression analysis

using SYSTAT computer program. The goodness of fit

of the tested mathematical models to the experimental

data was evaluated from the coefficient of determination

(R

2

). The higher the R

2

-value, the better is the goodness

of fit.

Pressure regulating

valve

Microwave

oven

Vacuum pump

Vacuum gauge

Condenser

Product

Balance

Fig. 1. Experimental microwave-vacuum drying apparatus.

Table 1

Levels of microwave-vacuum drying process variables

Variable

Name (units)

Level

1.68

1

0

1

1.68

Q

Microwave power (W)

115

150

200

250

285

P

System pressure (kPa)

6.5

10

15

20

23.5

T

Thickness (mm)

5.8

7.5

10

12.5

14.2

Table 2

Central composite design showing variable level combinations

Experiment no.

Variable levels

Q

P

T

1

1

1

1

2

1

1

1

3

1

1

1

4

1

1

1

5

1

1

1

6

1

1

1

7

1

1

1

8

1

1

1

9

1.68

0

0

10

1.68

0

0

11

0

1.68

0

12

0

1.68

0

13

0

0

1.68

14

0

0

1.68

15

0

0

0

16

0

0

0

17

0

0

0

18

0

0

0

19

0

0

0

20

0

0

0

514

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

2.4. Rehydration

Rehydration ratio (RR) which is a measure of rehydra-

tion characteristics of dried mushroom slices was deter-

mined by immersing 5 g of dried samples in distilled

water at 30 and 100

C temperatures. The water was

drained and the samples weighed at every 30 min intervals

for those immersed at 30

C and at every 2 min intervals

for those at 100

C. Triplicate samples were used. Rehydra-

tion ratio was defined as the ratio of weight of rehydrated

samples to the dry weight of the sample.

2.5. Scanning electron microscopy (SEM)

The structure of the dehydrated mushroom slices was

examined using a scanning electron microscope (JEOL

JSM-5800) coupled with an energy dispersive X-ray micro

analytical system (OXFORD ISIS-300). Thin slice of about

1 mm thick was cut from the dried samples and fixed on the

SEM stub, which were subsequently coated with gold in

order to provide a reflective surface for the electron

beam. Gold coating was carried out in a sputter coater

(BIO-RAD E-5200) under a low vacuum with the presence

of the inert gas, argon. The gold-coated samples were sub-

sequently viewed under the microscope.

3. Results and discussion

3.1. Drying kinetics

The drying curves for thin layer drying of mushroom

slices under microwave-vacuum drying and hot-air drying

conditions are shown in

, where the moisture content

of the samples at various time intervals and for varying

microwave power level and at various drying air tempera-

tures is recorded. The time required to reduce the moisture

content to any given level in microwave-vacuum drying

was dependent on the power level, being the highest at

115 W and lowest at 285 W. Mushroom having 92% initial

moisture content dried to a final moisture content of 6%

within 45 and 20 min at microwave power level of 115

and 285 W, respectively, at pressure level of 15 kPa. By

comparison, similar mushroom samples under convective

hot-air drying took 270 and 180 min at drying air temper-

ature 50 and 70

C, respectively. Thus, the microwave-

vacuum drying times were around 90% shorter at 285 W

and 75% shorter at 115 W than the corresponding convec-

tive air drying times.

further show the effect of changing the process

variables, namely microwave power, system pressure and

sample thickness on drying time during microwave-vacuum

drying. It is evident that the drying time decreases with the

increase in power output. When microwave power level

and product thickness remain constant, the drying rate at

higher vacuum level was slightly greater. However, the

effect of system pressure on drying time was not as signifi-

cant as that of microwave power. Concerning the effect of

the sample size on drying time, mushroom slices of smaller

0

2

4

6

8

10

12

14

0

50

100

150

200

250

300

350

Drying time, min

Moisture content, kg/kg dry matter

AD: 50

°C

AD: 70

°C

MVD: 115 W, 15 kPa

MVD: 285 W, 15 kPa

Fig. 2. Drying curves of air-dried (AD) and microwave-vacuum dried

(MVD) mushroom slice (10 mm thick).

0

2

4

6

8

10

12

14

0

10

20

30

40

Drying time, min

Moisture content, kg/kg dry matter

50

285 W

200 W

115 W

Fig. 3. Effect of microwave power levels on drying time for 10 mm thick

mushroom slices during MVD at 15 kPa system pressure.

0

2

4

6

8

10

12

14

0

10

20

30

40

50

60

Drying time, min

Moisture content, kg /kg dry matter

23.5 kPa

15 kPa

6.5 kPa

Fig. 4. Effect of pressure levels on drying time for 10 mm thick mushroom

slices during MVD at 200 W microwave power.

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

515

thickness exhibited more rapid dehydration. This can be

attributed to enhanced water transport phenomena within

the sample, which favour the thin samples.

The influence of microwave power on drying rate is

illustrated in

. There were no constant rates drying

under any of the test conditions. Although high moisture

foods like mushrooms can be expected to have a constant

rate of drying, this was not observed in the present study,

may be because of the thin (single) layer arrangement and

too rapid heating by microwaves, providing instant dry-

ing. As expected, higher drying rates were obtained with

higher microwave power. It can be seen from the figure

that the influence of power on drying rate is markedly

higher when the moisture is higher. At moisture content

of less than 4.0 kg/kg d.b. there is no difference in the dry-

ing rates among different power levels, indicating the sig-

nificance of internal resistance to mass transfer at low

water content in the material. The amount of microwave

energy absorbed by the material depends upon its dielec-

tric properties and the electric field strength (

). As the values of dielectric constant and loss factors

are higher at higher moisture content of the material,

obviously the material absorbs more microwave power

and heating is faster at high moisture content. As drying

progressed, the loss of moisture in the product decreases

the absorption of microwave power and resulted in a

fall in the drying rate during the later part of drying

(

Kharaisheh, Cooper, & Magee, 1995; Sharma & Prasad,

). Microwave heating under vacuum resulted in large

increase in drying rates (almost three to five-folds) as

compared to hot-air drying throughout the drying pro-

cess.

3.2. Modeling of the thin layer drying data of mushroom

slices

lists the model constants obtained by applica-

tion of exponential and Page’s equation to the experimen-

tal drying data. The empirical Page’s model gave better fit

for the drying data under all conditions tested with higher

R

2

(coefficient of determination) values. A good agreement

was found between the experimental and fitted values with

the R

2

-values of greater than 0.99 (

). The drying con-

stant (K) increased from 0.017 to 0.03 min

1

with the

increase in drying air temperature from 50 to 70

C for

7.5 mm thick mushroom slices. It can be seen that K- and

k-values for microwave-vacuum drying were higher than

hot-air drying. In microwave-vacuum drying of mushroom

slices of a particular thickness, these values were found to

increase as the microwave power was increased and pres-

sure was reduced. This can be attributed to the fact that

higher microwave power, lower pressure and smaller sam-

ple size help in increasing the driving force of heat and

mass transfer. For parameter n, it did not possess a clear

trend. For air drying, the n-values were close to one where

as in case of microwave-vacuum method the values were

more than one. The values for parameters ‘K’, ‘k’ and ‘n’

are in close proximity to those reported in the literature

for button mushrooms and other products (

The effect of process variables (microwave power, sys-

tem pressure and thickness) on rate constants were studied

by response surface method and fitting the data to a second

order

polynomial

model.

The

analysis

of

variance

(ANOVA) in

shows the significance of the models

and individual model terms. The models are found highly

significant (p < 0.05) with R

2

-values more than 0.86 (Eqs.

). The rate constant, K was highly affected by

microwave power and slice thickness, as the linear as well

as quadratic terms of these variables are significant. In case

of Page’s model constant, k, the linear effect of all the pro-

cess variables were found significant, with microwave

power having strongest effect as can be seen from

corresponding F-values. Significant lack of fit of the models

implied that a high proportion of the variability was

0

10

20

30

40

50

60

70

80

0

8

10

12

14

Moisture content, kg/kg dry matter

Drying rate, kg water/kg dry matter-hr

MVD: 285 W, 15 kPa

MVD: 200 W, 15 kPa

MVD: 115 W, 15 kPa

AD: 70

°C

AD: 50

°C

2

4

6

Fig. 6. Comparison of drying rate for microwave-vacuum drying and air

drying of 10 mm thick mushroom slices.

0

2

4

6

8

10

12

14

0

10

20

30

Drying time, min

Moisture content, kg /kg dry matter

40

6 mm

10 mm

14 mm

Fig. 5. Effect of slice thickness on drying time during MVD of mushroom

slices at 200 W microwave power and at 15 kPa system pressure.

516

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

not explained by the data. The variation of ‘K’ and ‘k’

with microwave power and slice thickness are depicted in

Regression analysis of the drying rate constant, K and k

versus MW power (Q), system pressure (P) and thickness

(T) yielded the following second order equations:

Table 3

Effect of various drying conditions on parameters of exponential and empirical Page’s model

Drying method

Thickness (mm)

Air temperature (

C)

Microwave power (W)

Pressure (kPa)

Model parameters

Exponential

Page

K (min

1

)

R

2

k (min

1

)

n

R

2

AD

7.5

50

–

–

0.017

0.987

0.025

0.997

0.996

60

–

–

0.026

0.990

0.028

1.02

0.994

70

–

–

0.030

0.995

0.033

0.98

0.995

12.5

50

–

–

0.011

0.995

0.011

0.985

0.996

60

–

–

0.014

0.994

0.012

1.06

0.994

70

–

–

0.020

0.996

0.019

1.034

0.995

MVD

7.5

–

150

10

0.110

0.997

0.074

1.168

0.999

–

20

0.092

0.995

0.055

1.197

0.996

–

250

10

0.175

0.997

0.099

1.289

0.999

–

20

0.157

0.997

0.085

1.281

0.999

12.5

–

150

10

0.082

0.985

0.024

1.482

0.998

–

20

0.080

0.986

0.023

1.471

0.997

–

250

10

0.137

0.994

0.064

1.345

0.999

–

20

0.129

0.990

0.048

1.443

0.999

AD—air drying; MVD—microwave-vacuum drying.

Q = 150 W

P = 20 kPa

0

7

14

21

28

35

Time, min

0.0

0.2

0.4

0.6

0.8

1.0

MR

Q = 250 W

P = 20 kPa

0

5

10

15

20

25

Time, min

0.0

0.2

0.4

0.6

0.8

1.0

Q = 150 W

P = 10 kPa

0

7

14

21

28

35

Time, min

0.0

0.2

0.4

0.6

0.8

1.0

Q =250 W

P =10 kPa

0

5

10

15

20

25

Time, min

0.0

0.2

0.4

0.6

0.8

1.0

MR

MR

MR

Fig. 7. Moisture ratio (MR) versus time comparing experimental curves with the predicted one (–) by Page’s equation for microwave-vacuum drying of

mushroom.

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

517

K

¼ 0:434 1:03 10

3

Q

0:011 P 0:04 T

þ 4:17 10

6

Q

2

þ 2:7 10

4

P

2

þ 2:15 10

4

T

2

þ 1:35 10

5

QP

2:7 10

5

QT

7:0 10

5

PT

ðR

2

¼ 0:93Þ;

ð3Þ

k

¼ 0:342 6:0 10

4

Q

9:28 10

3

P

0:034T

þ 2:24 10

6

Q

2

þ 2:38 10

4

P

2

þ 1:24 10

3

T

2

5:0 10

6

QP

þ 1:0 10

5

QT

þ 1:6 10

4

PT

ðR

2

¼ 0:86Þ.

ð4Þ

3.3. Rehydration characteristics

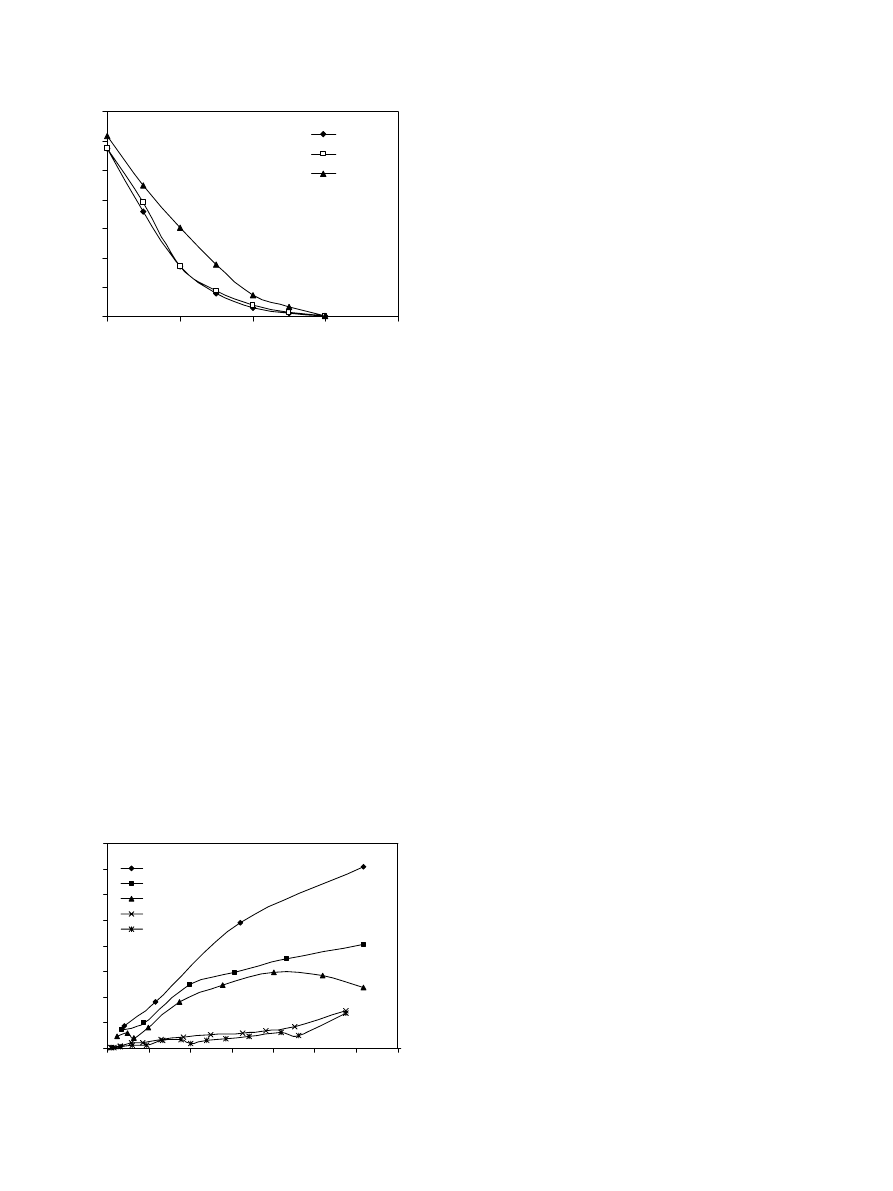

The rehydration curves of microwave-vacuum dried

mushroom samples, both at ambient (30

C) and at

100

C water temperatures, as affected by microwave

power and pressure levels are shown in

.

In all the cases the amount of moisture absorbed increases

with rehydration time, but at a decreasing rate up to sat-

uration level. The rehydration stabilized in about 10 min

at 100

C and in 3 h at 30 C and the rehydration ratio

was in the range of 2.3–3.4 under various drying condi-

tions. Rehydration properties were improved by drying

at lower system pressure and higher microwave power

as indicated by higher values of rehydration ratio. Simi-

lar results were reported by

(1996), Durance and Wang (2002), Pappas, Tsami, and

Marinos-Kouris (1999)

. The regression model for RR

relating the microwave-vacuum drying process variables

was found as

Table 4

ANOVA showing the linear, quadratic and cross-product effect of the variables on rate constants and rehydration ratio

Source of variation

df

K

k

RR

Mean square

F-value

Mean square

F-value

Mean square

F-value

Model

9

1.85

· 10

3

14.46

9.21

· 10

4

6.93

0.16

Q

1

1.10

· 10

2

87.27

3.58

· 10

3

26.96

0.11

2.44

P

1

2.01

· 10

4

1.57

7.92

· 10

4

5.96

0.61

T

1

9.98

· 10

4

7.78

2.30

· 10

3

17.42

0.34

Q

2

1

1.57

· 10

3

12.21

4.54

· 10

4

3.43

0.012

0.27

P

2

1

6.50

· 10

4

5.06

5.13

· 10

4

3.87

0.16

3.75

T

2

1

2.60

· 10

3

20.26

8.63

· 10

4

6.50

0.087

2.02

QP

1

9.11

· 10

5

0.71

1.25

· 10

5

0.094

0.017

0.40

QT

1

9.11

· 10

5

0.71

1.25

· 10

5

0.094

0.053

1.22

PT

1

6.12

· 10

6

0.048

3.21

· 10

5

0.24

0.021

0.49

Residual

10

1.28

· 10

4

1.32

· 10

4

0.043

Lack of fit

5

2.54

· 10

4

94.07

2.55

· 10

4

16.59

0.079

Pure error

5

2.70

· 10

6

1.51

· 10

5

0.0075

Total

19

df—Degree of freedom; F-ratio of variance estimate.

*

Significant at 1%.

**

Significant at 5%.

0.065

0.104

0.143

0.182

0.221

K (1/min)

115

158

200

243

285

6.0

8.0

10.0

12.0

14.0

Q (W)

T (mm)

(a)

0.022

0.045

0.068

0.090

0.113

k (1/min)

115

158

200

243

285

6.0

8.0

10.0

12.0

14.0

Q (W)

T (mm)

(b)

Fig. 8. Effect of microwave power and slice thickness on (a) drying rate constant (K) and (b) Page equations parameter (k), during microwave-vacuum

drying at 15 kPa pressure.

518

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

RR

¼ 3:94 þ 0:0156Q 0:173P 0:244T 1:13 10

5

Q

2

þ 4:24 10

3

P

2

þ 0:012T

2

1:85 10

4

QP

6:5 10

4

QT

þ 4:1 10

3

PT

ðR

2

¼ 0:77Þ.

ð5Þ

The response surface plot for rehydration ratio is shown

in

) it can be concluded

that the rehydration ratio depends mainly on pressure level

while sample thickness and microwave power had less

effect. While the rehydration ratio is positively correlated

with microwave power that of system pressure is negatively

correlated. As the pressure level decreases, the rehydration

ratio increases, owing to the increased drying rate and

creation of pores that are induced by vacuum conditions

(

). The higher RR at higher micro-

wave power can be attributed to the development of greater

internal stresses during drying at higher power levels. The

quick microwave energy absorption causes rapid eva-

poration of water, creating a flux of rapidly escaping

vapour which helps in preventing the shrinkage and case

hardening, thus improving the rehydration characteristics

Kharaisheh et al., 1995; Lyons, Hatcher, & Sunderland,

). It is also clear from

0.0

1.0

2.0

3.0

4.0

0

4

6

10

12

Rehydration time (min)

Rehydration ratio

Q = 285 W

Q = 200 W

Q = 115 W

(a)

0.0

1.0

2.0

3.0

4.0

0

0.5

1.5

2

2.5

Rehydration time (h)

Rehydration ratio

Q = 285 W

Q = 200 W

Q = 115 W

(b)

2

8

1

3

3.5

Fig. 9. Effect of microwave power on rehydration ratio of 10 mm thick

mushroom slices dried at 15 kPa pressure: (a) at 100

C and (b) at 30 C

water temperature.

0.0

1.0

2.0

3.0

4.0

0

4

8

10

12

Rehydration time (min)

Rehydration ratio

P = 23.5 kPa

P = 15 kPa

P = 6.5 kPa

(a)

0.0

1.0

2.0

3.0

4.0

0

2

4

Rehydration time (h)

Rehydration ratio

P = 23.5 kPa

P = 15 kPa

P = 6.5 kPa

(b)

3

1

2

6

Fig. 10. Effect of system pressure on rehydration ratio of 10 mm thick

mushroom slices dried at 200 W microwave power: (a) at 100

C and (b) at

30

C water temperature.

2.37

2.73

3.08

3.43

3.78

Rehydration Ratio

6.5

10.8

15.0

19.3

23.5

6.0

8.0

10.0

12.0

14.0

P (kPa)

T (mm)

Fig. 11. Effect of system pressure and thickness on rehydration ratio of

mushroom slices dried at 200 W microwave power.

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

519

that the rehydration capacity, both in terms of final

moisture content and speed is higher for the microwave-

vacuum dried samples in comparison to air-dried samples.

Microwave-vacuum drying creates a porous structure with

very little shrinkage than those obtained by air drying,

thereby providing better rehydration char-acteristics.

3.4. SEM

Effect of different drying methods and conditions on the

structure of dried mushrooms was observed under scan-

ning electron microscope. In air-dried samples (

there is very less open structure and pores as compared

to microwave-vacuum dried samples (

b and c), indi-

cating severe tissue shrinkage and collapse during air dry-

ing. The less shrinkage in the microwave-vacuum dried

samples may be due to the shorter drying time, lower dry-

ing temperature and some tissue expansion from internal

water vapour. Again the structure is more porous in sam-

ples dried under more vacuum conditions (

c) during

microwave-vacuum drying.

4. Conclusions

Microwave-vacuum drying of mushroom was much fas-

ter than conventional hot-air drying, particularly towards

the end of the drying process. The exponential as well as

empirical Page’s model adequately described the micro-

wave-vacuum drying data. Statistical analysis of the drying

data showed that drying rate constant was highly influ-

enced by microwave power while system pressure had high-

est influence on the rehydration characteristics of the

dehydrated mushroom in a p 6 0.05. Sample thickness also

appeared to be factor influencing the drying rate with thin-

ner sample resulting in quick drying. Microwave-vacuum

dried mushroom also created a more porous dehydrated

product, which rehydrated more quickly and more com-

pletely than the air dried product. The button mushroom

slices could be microwave-vacuum dried to 6% moisture

content (w.b.) in 25–30 min, avoiding any burning of the

product and with good rehydration characteristics.

References

AOAC (1984). Official methods of analysis of the Association of Official

Analytical Chemists (14th ed.). Washington, DC.

Arora, S., Shivhare, U. S., Ahmed, J., & Raghavan, G. S. V. (2003).

Drying kinetics of Agaricus bisporus and Pleurotus florida mushrooms.

Transaction of the ASAE, 46(3), 721–724.

Cui, Z. W., Xu, S. Y., & Sun, D. W. (2003). Dehydration of garlic slices by

combined microwave-vacuum and air drying. Drying Technology,

21(7), 1173–1184.

Drouzas, A. E., & Schubert, H. (1996). Microwave application in vacuum

drying of fruits. Journal of Food Engineering, 28, 203–209.

Drouzas, A. E., Tsami, E., & Saravacos, G. D. (1999). Microwave vacuum

drying of model fruit gel. Journal of Food Engineering, 39, 117–122.

Durance, T. D., & Wang, J. H. (2002). Energy consumption, density and

rehydration rate of vacuum microwave and hot air convection

dehydrated tomatoes. Journal of Food Science, 67(6), 2212–2216.

0.0

1.0

2.0

3.0

4.0

0

8

10

12

Rehydration time (min)

Rehydration ratio

MVD: 200W, 15 kPa

AD: 60

°C

2

4

6

Fig. 12. Comparison of rehydration ratio of microwave-vacuum and air-

dried mushroom slices.

Fig. 13. Scanning electron micrographs of dried mushroom: (a) air-dried

at 60

C, (b) microwave-vacuum dried at 20 kPa pressure and (c)

microwave-vacuum dried at 10 kPa.

520

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

Jasna, P. K., Sander, A., & Skansi, D. (2001). Comparison of convective,

vacuum and microwave drying chlorpropamide. Drying Technology,

19(1), 167–183.

Kar, A., & Gupta, D. K. (2003). Air drying of osmosed button

mushrooms. Journal of Food Science and Technology, 40(1), 23–27.

Kharaisheh, M. A. M., Cooper, T. J. R., & Magee, T. R. A. (1995).

Investigation and modeling of combined microwave and air drying.

Transaction of Institution of Chemical Engineers, 73(c), 121–126.

Kiranoudis, C. T., Tsami, E., & Maroulis, Z. B. (1997). Microwave vacuum

drying kinetics of some fruits. Drying Technology, 15(10), 2421–2440.

Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization of

vacuum microwave, air and freeze-dried carrot slices. Food Research

International, 31(2), 111–117.

Lyons, D. W., Hatcher, J. D., & Sunderland, J. E. (1972). Drying of a

porous medium with internal heat generation. International Journal of

Heat and Mass Transfer, 15(5), 897–905.

McLoughlin, C. M., McMinn, W. A. M., & Magee, T. R. A. (2003).

Microwave-vacuum drying of pharmaceutical powders. Drying Tech-

nology, 21(9), 1719–1733.

Mudgett, R. E. (1990). Developments in microwave food processing. In H.

E. Schwartzberg & M. A. Rao (Eds.), Biotechnology and food process

engineering. Basic symposium series (pp. 359–403). New York: Marcel

Dekker.

Mujumdar, A. S. (1995). Handbook of industrial drying (2nd ed.). New

York: Marcel Dekker.

Pappas, C., Tsami, E., & Marinos-Kouris, D. (1999). The effect of process

conditions on the drying kinetics and rehydration characteristics of

some microwave-vacuum dehydrated fruits. Drying Technology, 17

(1 and 2), 157–174.

Pravanjan, D. G., Ramaswamy, H. S., & Raghavan, G. S. V. (1995).

Microwave assisted convective air drying of thin layer carrots. Journal

of Food Engineering, 25, 283–293.

Sharma, G. P., & Prasad, S. (2001). Drying of garlic (Allium sativum)

cloves by microwave-hot air combination. Journal of Food Engineering,

50, 99–105.

Wardsworth, J. I., Velupillai, L., & Verma, L. R. (1990). Microwave-

vacuum drying of parboiled rice. Transactions of ASAE, 33(1),

199–210.

Woodroof, J. G., & Luh, B. S. (1986). Commercial fruit processing.

Westport, CN: The AVI Publishing Company.

Yongsawatdigul, J., & Gunasekaran, S. (1996a). Microwave vacuum

drying of cranberries, part I: Energy use and efficiency. Journal of Food

Processing and Preservation, 20, 121–143.

Yongsawatdigul, J., & Gunasekaran, S. (1996b). Microwave vacuum

drying of cranberries, part II: Quality evaluation. Journal of Food

Processing and Preservation, 20, 145–156.

S.K. Giri, S. Prasad / Journal of Food Engineering 78 (2007) 512–521

521

Document Outline

- Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms

Wyszukiwarka

Podobne podstrony:

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying kinetics and quality of vacuum microwave dehydrated garlic cloves and slices

Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum microwav

Drying kinetics and quality of potato chips undergoing different drying techniques

The drying kinetics of kale (Brassica oleracea) in a convective hot air dryer

Drying kinetics of apple cylinders under combined hot air–microwave dehydration

Energy Consumption and Colour Characteristics of Nettle Leaves during Microwave, Vacuum and Convecti

Microwave Drying of Parsley Modelling, Kinetics, and Energy Aspects

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

Improving nutritional value of dried blueberries combining microwave vacuum, hot air drying and free

Headspace Volatiles and Physical Characteristics of Vacuum microwave, Air, and Freeze dried Oregano

Thin layer modelling of the convective, microwave, microwave convective and microwave vacuum drying

Microwave vacuum drying of porous media experimental study and qualitative considerations of interna

Microwave vacuum drying of marine sediment determination of moisture content, metals and total carbo

więcej podobnych podstron