Drying kinetics and quality of beetroots dehydrated by combination

of convective and vacuum-microwave methods

Adam Figiel

*

Institute of Agricultural Engineering, Wrocław University of Environmental and Life Sciences, Wrocław, Poland

a r t i c l e

i n f o

Article history:

Received 5 November 2009

Received in revised form 30 December 2009

Accepted 23 January 2010

Available online 28 January 2010

Keywords:

Beetroots

Drying

Vacuum-microwaves

Shrinkage

Compressive strength

Colour

Rehydration

Antioxidant activity

a b s t r a c t

Beetroot cubes were dehydrated by convective drying in hot air at 60 °C and by the combination of con-

vective pre-drying (CPD) until moisture content 1.6, 0.6 or 0.27 kg/kg db and vacuum-microwave finish

drying (VMFD) at 240, 360 or 480 W. The control samples were obtained by freeze-drying (FD). The dry-

ing kinetics of beetroot cubes was described with an exponential function. VMFD significantly reduced

the total time of drying and decreased drying shrinkage in comparison with convective method. A critical

moisture content divided the temperature profile of samples during VMFD into increasing and falling

periods. At the falling temperature period a significant increase in the colour parameters L

*

, a

*

and b

*

was found. VM treated samples as well as FD ones exhibited lower compressive strength, better rehydra-

tion potential and higher antioxidant activity than those dehydrated in convection. Increasing the micro-

wave wattage and decreasing the time of CPD improved the quality of beetroot cubes dried by the

combined method.

Ó 2010 Elsevier Ltd. All rights reserved.

1. Introduction

Beetroots (Beta vulgaris) are rich in valuable, active compounds

such as carotenoids (

), glycine betaine, (

), saponins (

), betacyanines (

), folates (

), betanin, polyphe-

nols and flavonoids (

). Therefore, beetroot ingestion

can be considered a factor in cancer prevention (

). However, fresh beetroots are exposed to spoilage due to

their high moisture content. One of the preservation methods

ensuring microbial safety of biological products is drying (

). Dried beetroots can be consumed directly in the form

of chips as a substitute of traditional snacks, that are rich in trans

fatty acids (

), or after easy preparation as a compo-

nent of instant food (

Convective drying in hot air is still the most popular method ap-

plied to reduce the moisture content of fruits and vegetables (

), including beetroots (

Kamin´ski et al., 2004; Shynkaryk

). However, this method has several disadvantages

and limitations; for instance, it requires relatively long times and

high temperatures, which causes degradation of important nutri-

tional substances (

) as well as colour alteration

). Another disadvantage of that method is shrink-

age, which is a result of tissue collapse caused by volume reduction

due to the loss of moisture as well as the presence of internal forces

(

Sjöholm and Gekas, 1995; Mayor and Sereno, 2004

Some novel drying methods are free of those weaknesses typi-

cal for convective drying. Nevertheless, their application in exclu-

sive form involves other problems such as low productivity, high

costs or technical inconveniences. Hence, hybrid techniques com-

posed of complementary drying methods which donate their

advantages are of the highest interest. Convective drying in hot

air is still worth consideration due to the satisfactory efficiency

at the initial period of dehydration characterized by relatively high

drying rate and large capacity. Therefore convective drying should

be followed by a method which can ensure adequate drying rate at

the final period of dehydration and high quality of the dried prod-

uct. Shrinkage and texture are considered to be quality attributes

of dried product (

). Colour is another quality factor

of a dried product (

Yongsawatdigul and Gunasekaran, 1996

), being

not only an indicator of the changes occurring in the material dur-

ing drying (

), but also an important attribute boost-

ing the attractiveness of a food product (

). The

most suitable method satisfying these requirements is drying with

application of microwaves under vacuum.

Drying with the microwave method under vacuum is a modern,

efficient method of food preservation (

).

During vacuum-microwave (VM) drying the energy of microwaves

is absorbed by water located in the whole volume of the material

0260-8774/$ - see front matter Ó 2010 Elsevier Ltd. All rights reserved.

doi:

10.1016/j.jfoodeng.2010.01.029

*

Tel.: +48 71 3205730; fax: +48 71 3482486.

E-mail address:

Journal of Food Engineering 98 (2010) 461–470

Contents lists available at

Journal of Food Engineering

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / j f o o d e n g

being dried. This creates a large vapour pressure in the centre of

the material, allowing rapid transfer of moisture to the surround-

ing vacuum and preventing structural collapse (

).

As a consequence, the rate of drying is considerably higher than

in traditional methods of dehydration (

).

A decisive factor enhancing drying rate is the wattage of micro-

waves (

Andres et al., 2004; Figiel, 2006

). The puffing phenomenon,

that accompanies the rapid process of dehydration, creates a por-

ous texture of the food and facilitates obtaining a crispy and deli-

cate texture (

), and in this way it reduces the

product’s density as well as shrinkage.

The VM technique has already been satisfactory applied to re-

duce the moisture content of many plant materials, such as carrots

(

), cranberries (

), strawberries

(

), peanuts (

), bananas (

). However, at the beginning

of VM dehydration the intensive water evaporation from the mate-

rial being dried may exceed the vacuum pump capacity. This

would require a reduction in the raw material subjected to drying

or application of a large vacuum installation. This problem can be

overcome by pre-drying of the material using convective drying in

hot air which is very efficient in the initial period of dehydration.

As a result of pre-drying the mass loads of a VM equipment can

be radically decreased (

). Pre-drying of the material

by convective method before VM finish drying (VMFD) reduced the

total cost of dehydration and improved the quality of dried toma-

toes (

) and nutritional value of strawber-

ries (

).

No scientific work has yet been reported on the combined dry-

ing of beetroots. The combined method consisting of CPD and

VMFD (CPD–VMFD) could make a significant contribution to the

vegetable processing industry. However, it is not obvious when

convective drying should be replaced with VM method and what

microwave wattage is supposed to be applied to ensure the opti-

mal conditions of beetroots dehydration. Therefore the aim of this

work was to determine the effect of microwave power and the

level of CPD on the drying kinetics as well as on some quality fac-

tors of VMFD beetroot cubes in terms of shrinkage, texture, colour,

rehydration potential and antioxidant activity. The assumption

that these quality factors are in some ways interrelated, due to

the decisive impact of water content on a large majority of biolog-

ical material properties, induces the necessity to explain the phe-

nomena which occur within the material subjected to combined

drying.

2. Materials and methods

2.1. Sample preparation

Beetroots of ‘‘Alto F1” variety were cultivated in a field situated

close to Wroclaw (Poland). Roots of similar size were washed and

cut into 10 mm cubes by using of a cutter equipped with a knife

moving perpendicularly to a horizontal base. The base was covered

with thick rubber. To ensure proper size of the samples a vertical

base was fixed at 10 mm distance from the action plain of the

knife. Before drying the cubes were mixed in a plastic container

and then divided into 180 g portions.

2.2. Drying

The beetroot cubes were subjected to drying with three meth-

ods. The first method was hot air convective drying, the second

one was a combination CPD–VMFD, while the third one was

freeze-drying (FD). The beetroot cubes obtained by FD were con-

sidered as control samples. Convective drying was performed in a

drier designed and built in the Institute of Agriculture Engineering

(Wroclaw, Poland). The air temperature and velocity were 60 °C

and 1.8 m/s, respectively. The portions of 180 g were spread on a

round 100 mm tray. The tray was placed on top of a drying pipe.

The convective dryer, equipped with six pipes, enabled simulta-

neous drying of six portions. In the combined method CPD was car-

ried out until the three levels of moisture content: 1.6, 0.6 and

Nomenclature

a, b, c

function parameters

A, B, C

pre-drying levels

AC

absorption capacity (kg/kg)

AC

R

absorption capacity rate (kg/kg/h)

CPD

convective pre-drying

CPD–VMFD combination of convective pre-drying and vacuum-

microwave finish drying

db

dry basis

dw

dry weight

D

R

drying rate (min

1

)

FD

freeze-drying

F

max

breaking force (N)

FRAP

ferric reducing ability of plasma

FSE

fit standard error

k

drying constant (min

1

)

L

*

degree of lightness

a

*

degree of redness

b

*

degree of yellowness

m

A

mass of water absorbed from humid air (kg)

m

D

mass of water removed during drying (kg)

M

moisture content (kg/kg db)

M

e

equilibrium moisture content (kg/kg db)

M

0

initial moisture content (kg/kg db)

M

R

moisture ratio

MP

microwave power

MRPs

Maillard reaction products

P

1

, P

2

breaking points

R

2

coefficient of determination

S

surface of beetroot cube cross-section (mm

2

)

t

time (min, h)

T

Trolox

TPTZ

2,4,6-tri(2-pyridyl)-1,3,5-triazine

V

R

relative volume of the dried material (m

3

/m

3

)

V

volume after drying (m

3

)

V

0

volume before drying (m

3

)

VM

vacuum-microwave

VMFD

vacuum-microwave finish drying

Greek symbols

a

significance level

r

max

breaking stress (MPa)

Subscripts

a, b, c

indicate significant differences

Superscripts

u, x, y, z indicate significant differences

462

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

0.27 kg/kg db. Each CPD portion was divided into three equal por-

tions. The divided portions were dehydrated by VMFD in SM-200

dryer (Plazmatronika, Wroclaw, Poland) at 360 W microwave

power. Samples pre-dried until 0.6 moisture content were addi-

tionally dried by VMFD at 240 or 480 W. The pressure in the vac-

uum-drum ranged from 4 to 6 kPa and the drum was revolving

at 6 rev/min. During FD (freeze drier OE-950, Hungary) the pres-

sure was reduced to 65 Pa. The temperature in the drying chamber

was 60 °C, while the heating plate reached 30 °C.

The drying kinetics for convective drying and VMFD was deter-

mined on the basis of mass losses of beetroot cubes when the ini-

tial moisture content M

0

amounted to 10.25 kg/kg db. The

experiment was interrupted whenever the mass of dried cubes

was measured. The moisture ratio M

R

was determined from the

equation:

M

R

¼

MðtÞ M

e

M

0

M

e

ð1Þ

The equilibrium moisture content M

e

was determined at the fi-

nal stage of drying as an asymptotic value of the function fitted to

the experimental points using Table Curve 2D Windows v2.03

(

The moisture content of dehydrated cubes subjected to quality

estimation was in the range 0.053 to 0.15 kg/kg db. This moisture

content was determined by drying the previously ground samples

in vacuum dryer (SPT-200, ZEAMiL Horyzont, Krakow, Poland) for

24 h at temperature 60 °C. The result was the mean value of two

repetitions.

2.3. Temperature measurement

During VM drying the vacuum-drum was rotating in order to

avoid the local overheating of beetroot samples. Nevertheless,

the temperature of individual cubes differed despite of the drum

rotation. The temperature of beetroot cubes was measured with

an infrared thermometer immediately after taking them out of

the VM dryer. The external temperature of most heated cubes

was recorded. It was supposed that the temperature measured

with this method reflected the course of mean temperature during

drying. A direct internal temperature measurement of the cubes in

the drying chamber under vacuum is practically not possible be-

cause the measuring elements inserted into the dried material

are heated by the microwave emission.

2.4. Shrinkage

Shrinkage, which occurred during drying as a result of water

evaporation, was evaluated by determination of the relative vol-

ume of dried material. The relative volume was the ratio of beet-

root cube volume after drying to that before drying:

V

R

¼

V

V

0

ð2Þ

The volume of beetroot samples was calculated by multiplica-

tion of three basic sizes measured with the use of a slide caliper.

Seven replications were performed on samples with the same

moisture content.

2.5. Compressive test

The compressive strength of dried beetroot cubes was deter-

mined with an Instron 5544 strength-testing machine (Instron,

High Wycombe, UK) equipped with one of two replaceable strain

gauges of 2 kN or 100 N range. The individual cubes were com-

pressed between two parallel plates with a speed of 6 mm/min.

The contact surfaces of the cubes deformed by shrinkage were

gently smoothed using sand paper in order to avoid local ruptur-

ing.

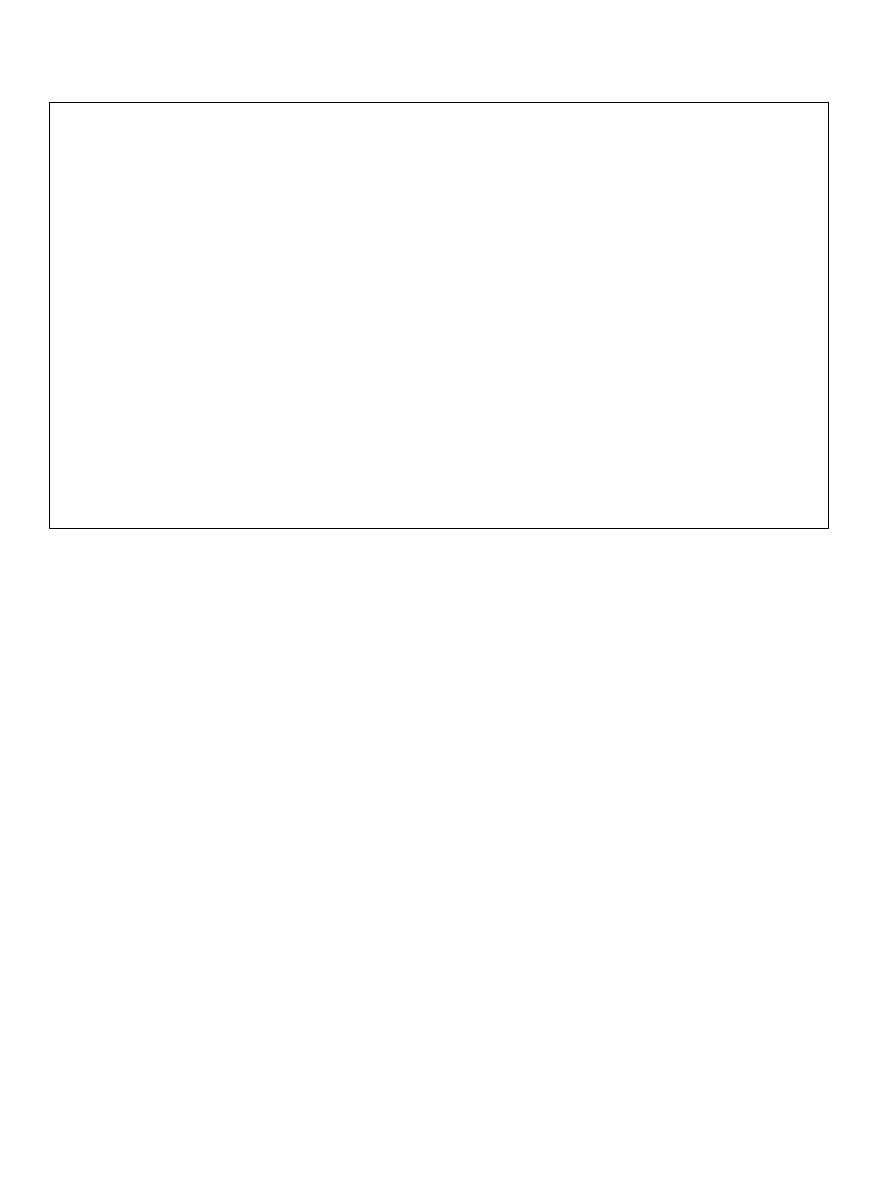

shows typical compressive curves for a very dry sample

with breaking point P

1

and for a sample of high moisture content

with breaking point P

2

. It was assumed that beyond the breaking

point the compressive force is decreasing or the increase of that

force is going along the straight line indicating the yielding period

of compression. The breaking stress was the ratio of the breaking

force to the cross-section of compressed beetroot cubes:

r

max

¼

F

max

S

10

3

ð3Þ

Seven replications were performed on samples with the same

moisture content.

2.6. Rehydration test

The maximally dried samples of beetroot were subjected to a

rehydration test. Before that these samples were placed in an exs-

iccator for 3 months in order to reduce and equalise their moisture

content. The samples of ca. 0.7 g weight were placed in a WK111

340

GmbH (Germany) chamber at 21 °C and 95% relative humidity. The

curves of absorption capacity were determined at certain intervals

for 50 h on the basis the weight of samples kept in the chamber

compared to the initial weight, which was almost equal to the

dry mass. Longer duration of rehydration exposed the beetroot

samples to microbial spoilage. These samples were weighed each

time, when out of the chamber, in plastic containers on a balance

with 0.001 g accuracy. Absorption capacity AC, expressing the de-

gree of water restoration in dry material resulting from absorption

of water vapour relative to water content before drying, was calcu-

lated from an equation similar to that proposed by

and

AC ¼

m

A

m

D

ð4Þ

Each experimental point was the result of three replicates.

2.7. Colour measurement

Colour of dried samples was evaluated by a Minolta Chroma

Meter CR-200 (Minolta Co. Ltd., Osaka, Japan). Instrumental colour

data were expressed as CIE L

*

, a

*

, b

*

coordinates, which define the

colour in a three-dimensional space: L

*

(dark–light), a

*

(redness–

green) and b

*

(yellowness–blueness). Samples before measurement

were ground using an electric mill. Colour measurements were

performed in triplicate.

Deformation

Compressiv

e f

orce

P

1

(

F

1 max

)

P

2

(

F

2 max

)

Fig. 1. Typical compressive curves for a very dry beetroot sample with breaking

point P

1

and for a sample of high moisture content with breaking point P

2

.

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

463

2.8. Antioxidant activity

The total antioxidant potential of beetroot samples was deter-

mined using the ferric reducing ability of plasma (FRAP) assay as

described by

. In this method a potential

antioxidant reduces the ferric ion (Fe

3+

) to the ferrous ion (Fe

2+

);

the latter forms a blue complex (Fe

2+

/TPTZ), which increases

absorption at 593 nm. FRAP reagent was prepared by mixing ace-

tate buffer (300

l

M, pH 3.6), a solution of 10

l

M TPTZ in 40

l

M

HCl, and 20

l

M FeCl

3

at 10:1:1 (v/v/v). The reagent (300

l

L) and

sample solutions (10

l

L) were mixed thoroughly. The absorbance

was taken at 593 nm after 10 min. Standard curve was prepared

using different concentrations of Trolox. All solutions were pre-

pared daily. The results were expressed in

l

M Trolox per 100 g

dry weight. All determinations were performed in triplicate.

2.9. Statistical analysis

The results obtained in the study were subjected to statistical

analysis. Standard deviations were estimated by means of Micro-

soft Excel (Microsoft Office 2000 SR-1 Professional). Table Curve

2D Windows v2.03 (Jandel Scientific Software, USA) enabled math-

ematical modelling with the best determination coefficient. The re-

sults obtained were evaluated by statistical analysis with the use of

the Statistica v. 8.0 (StatSoft, Inc., Tulsa, USA). Homogeneous

groups were determined with the Duncan’s multiple range test at

significance level

a

= 0.05. The one-way analysis of variance was

applied in order to find out if the differences in the mean values

estimated were significant.

3. Results

3.1. Drying kinetics

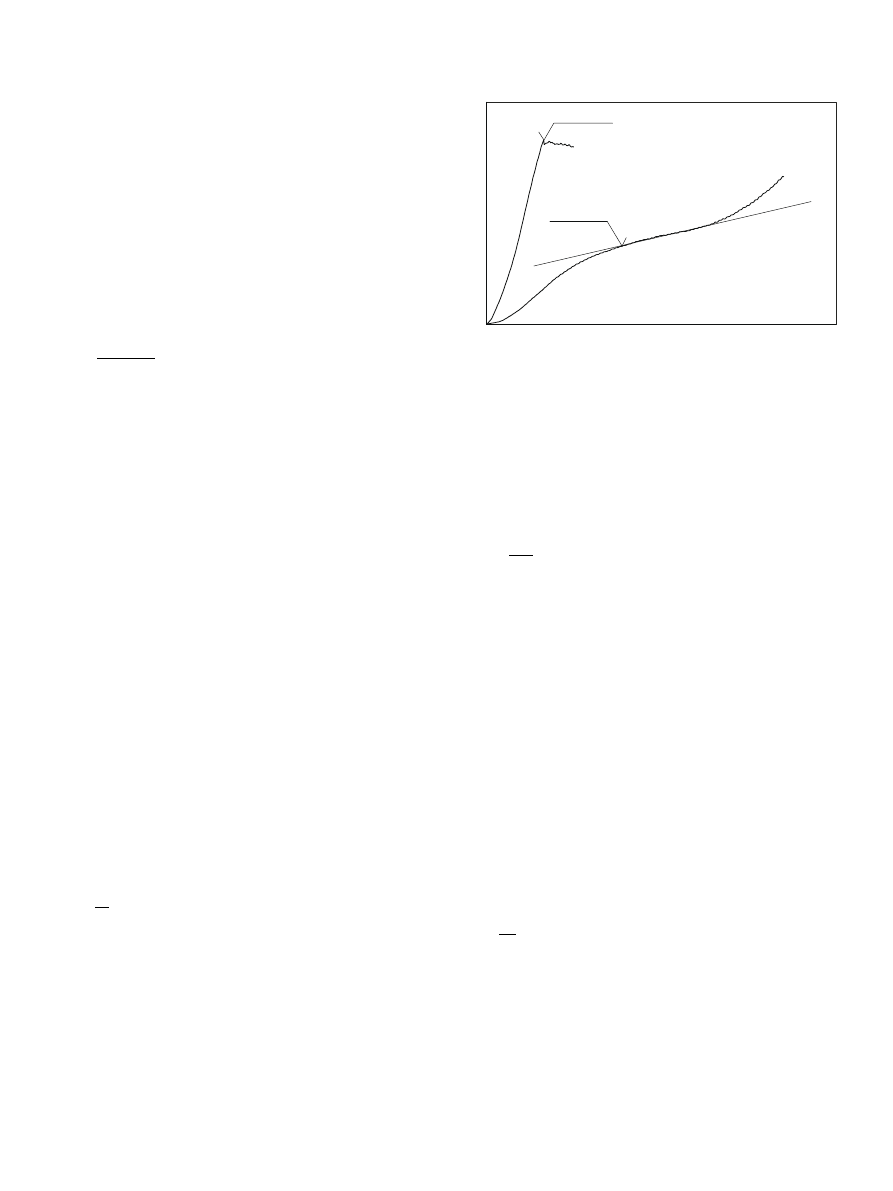

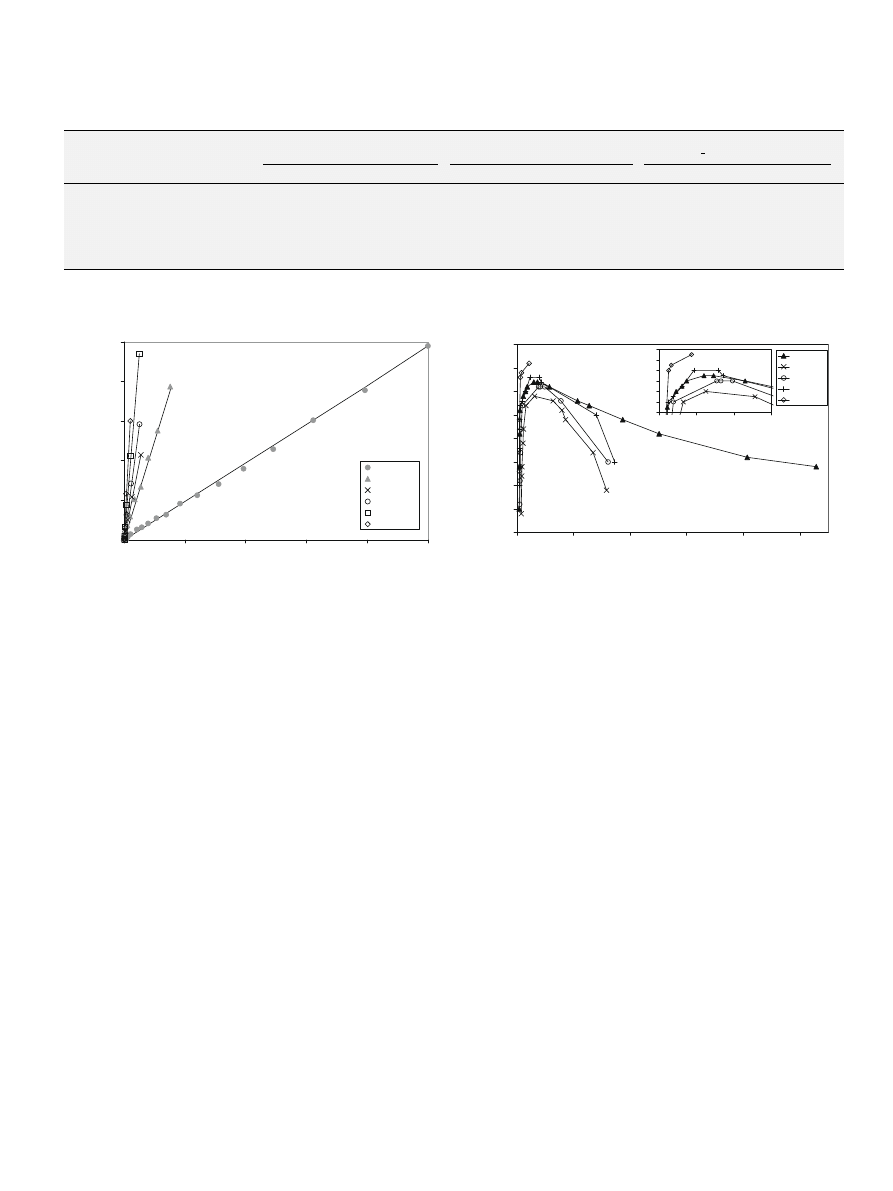

Drying kinetics of beetroot cubes dehydrated by the convective

as well as by combined method is shown in

. For both the

methods the decrease in moisture ratio M

R

in time was described

by an exponential function:

M

R

¼ a e

kt

ð5Þ

For convective drying the a value amounted to 1, and Eq.

might be simplified to the Lewis’ model:

M

R

¼ e

kt

ð6Þ

For VMFD the a value was lower than 1 (

). This value was

the lower the longer was the time of convective pre-drying.

In the initial phase of convective drying the water loss is rela-

tively rapid, whereas the successive dynamics of water loss de-

creases and drying with that method begins to be time-

consuming (

). Application of VMFD enabled consid-

erable shortening of the total time of drying. The time of drying

with the convective method necessary to reach a moisture content

of 0.05 kg/kg db reached ca. 420 min. With the early application of

VMFD (at microwave power 360 W) the time was ca. four times

shorter. The total time of drying was shorter when the VMFD dry-

ing was introduced earlier and the applied power of microwaves

was higher. A similar result was obtained with CPD-VMFD of pears

(

Differentiation of Eq.

enabled drying rate estimation:

D

R

¼

dM

R

dt

ð7Þ

Because the complex form of Eq.

is exponential,

dM

R

dt

¼ k a e

kt

ð8Þ

Taking into consideration Eq.

again,

dM

R

dt

¼ k M

R

ð9Þ

and finally according to Eq.

D

R

¼ k M

R

ð10Þ

The relationship between D

R

and M

R

for convective drying and

for VMFD (

) is linear according to Eq.

. The slop of the

straight lines, which represent this relationship, determines the

values of the drying constant k (

). The linear course of

experimental points displayed in

confirms that Eqs.

describe adequately the drying kinetics of beetroot cubes.

When drying by convective method the value of D

R

diminished

from 0.02448 to 0.0 min

1

. However, the introduction of VMFD

at M

R

equal 0.16, which corresponded to 1.6 kg/kg db, resulted in

the jump of D

R

from 3.51 10

3

to 19.35 10

3

min

1

. The high-

est increase in D

R

, from 1.33 10

3

to 23.50 10

3

min

1

, was

found for VMFD at 480 W and the lowest one, from 1.33 10

3

to 10.74 10

3

min

1

, occurred for VMFD at 240 W. On the other

hand, the highest k value 747.0 10

3

min

1

was found for the

sample maximally pre-dried by convective method, while the low-

est one 124.0 10

3

min

1

for the sample minimally pre-dried. It

can be stated that the higher the value of k the higher D

R

for as-

sumed M

R

. It was found that both the increase in microwave power

and the level of CPD increased the k value.

The positive effect of microwave power on k value was ex-

pected. This expectation was supported by the results of investiga-

tions made on other biological materials such as mint leafs

(

) and apples (

). However,

the effect of the level of CPD on D

R

during VMFD has not yet been

studied and needs more consideration. Namely, during convective

drying the external heating is associated with an inward gradient

of moisture. Under such drying conditions water is evacuated from

the surface of the dried material to ambient as a vapour. The sur-

face is all the time supplied with water diffusing from the deeper

and deeper parts of the material. This creates no uniform distribu-

tion of water within the material. Longer CPD enhance transforma-

tion of microwave energy into heat energy by water dipoles

located deeper and more bound with the cellular system of the

material (

). As a result, at the beginning of VMFD the in-

ner temperature of more pre-dried material is higher than the tem-

perature of less pre-dried one of the same moisture content. This

temperature, associated with the pressure within the material

(

), affects the current drying rate.

0.00

0.04

0.08

0.12

0.16

75

90

105

120

135

150

A

B

C

0.00

0.20

0.40

0.60

0.80

1.00

0

100

200

300

400

500

Time (min)

Moisture r

atio

Convection

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

A

B

C

Fig. 2. Drying kinetics of beetroot cubes dehydrated by convection and by

combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/

kg db and VMFD at microwave power 240, 360 or 480 W).

464

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

It is hard to measure directly the inner temperature of the

material being VM dried. However, the assumption that external

temperature measured with an infrared thermometer reflexes

the inner temperature may support the considerations made

above.

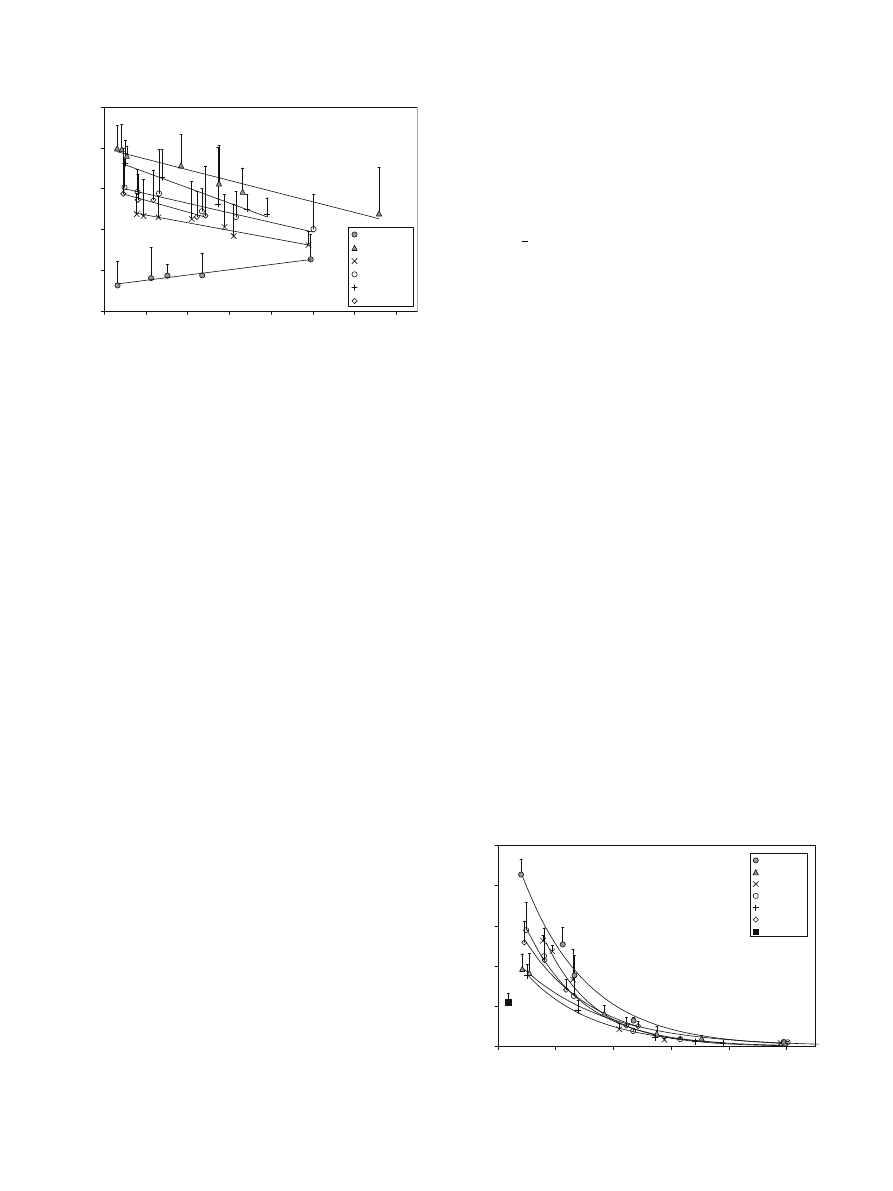

3.2. Temperature

During VMFD an increase in the beetroot cubes temperature

was observed until a critical moisture content. Beyond that mois-

ture content the samples temperature was decreasing (

The peak temperature 86 °C was recorded for VMFD beetroot cubes

maximally pre-dried and the lowest one, amounting to 79 °C, for

VMFD cubes dehydrated with the lowest microwave wattage. It

was found that the increase in microwave wattage to 480 W in-

creased the peak temperature to 83 °C. These results confirm the

explanations regarding the effect of microwave power and the le-

vel of pre-drying on the drying rate. However, according to those

explanations the peak temperature of the samples pre-dried to

1.6 kg/kg db should be lower than those determined for the sample

pre-dried to 0.6 kg/kg db, while the data presented in

show a

reverse relationship for this case. This discrepancy follows from the

relatively long time of microwave energy accumulation by the

whole volume of those samples pre-dried to 1.6 kg/kg db. Never-

theless, the temperature gradient, resulting from the temperature

distribution within the material, is enhanced by longer pre-drying.

Another problem which needs clarification is the presence of

peak temperature. During convective drying the temperature of

material is successively increasing reaching the temperature of

hot air at the end of drying (

clamed that with VM drying the temperature of

dehydrated banana slices was increasing reaching the highest va-

lue at the end of drying when the moisture content ranged from

0.05 to 0.08 kg/kg db. The decreasing in sample temperature at

the final stage of drying was not recorded. In this study the peak

temperatures were found for the critical moisture contents in the

range from 0.09 to 0.15 kg/kg db. One can presume, that the course

of temperature versus moisture content depends on two phenom-

ena. The first is the generation of heat energy by water dipoles in

microwave field (

) while the other one is the absorbing

of that energy by water evaporating from the surface of the mate-

rial. The increase in the material temperature until critical mois-

ture content results from the excess of the energy generated over

the energy necessary for water evaporation. Naturally, the

amounts of water generating the energy and water evaporating

are decreasing with decreasing moisture content. Beyond the crit-

ical moisture content the energy generated by water dipoles is

lower than the sum of the energy necessary for water evaporation

and that transferred from the material to the ambient of lower

temperature. However, this explanation needs further, compre-

hensive investigation.

3.3. Shrinkage

The relative volume (V

R

) can be treated as a parameter describ-

ing the ability of a material being drying to shrink – the lower V

R

the higher shrinkage of the material. The V

R

determined for VMFD

beetroot samples was significantly higher as compared with sam-

ples dried by convection (

), despite the noticeably high stan-

dard errors of the mean values of relative volume. These high

standard errors resulted from the anisotropic nature of biological

Table 1

Values of the parameters a, b and k of the functions describing the drying kinetics, relative volume and breaking stress of beetroot samples.

Drying method

CPD level

(kg/kg db)

MP (W)

Drying kinetics

Relative volume

Breaking stress

M

R

¼ a e

kt

V

R

¼ a M þ b

r

max

¼ a e

M

b

a

k

R

2

FSE

a

b

R

2

FSE

a

b

R

2

FSE

CPD–VMFD

1.6

360

0.156

0.124

0.9949

3.440 10

3

0.653

0.432

0.9564

6.875 10

3

7.251

0.0292

0.9959

29.81 10

3

0.6

240

0.055

0.195

0.9999

0.165 10

3

0.471

0.351

0.9343

4.012 10

3

61.37

0.0173

0.9870

72.83 10

3

0.6

360

0.051

0.288

0.9984

0.811 10

3

0.585

0.385

0.9636

4.340 10

3

30.55

0.0197

0.9966

38.31 10

3

0.6

480

0.050

0.471

0.9992

0.610 10

3

0.939

0.436

0.9786

4.537 10

3

11.59

0.0234

0.9966

24.40 10

3

0.27

360

0.020

0.747

0.9982

0.376 10

3

0.720

0.386

0.9635

2.814 10

3

16.20

0.0236

0.9883

58.51 10

3

Convection

1.0

0.024

0.9994

6.455 10

3

0.322

0.215

0.9649

2.520 10

3

28.09

0.0226

0.9903

93.64 10

3

CPD = convective pre-drying, VMFD = vacuum-microwave finish drying, MP = microwave power, R

2

= coefficient of determination, FSE = fit standard error.

0

0.005

0.01

0.015

0.02

0.025

0

0.2

0.4

0.6

0.8

1

Moisture ratio

Dr

ying r

ate (min

-1

)

Convection

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

Fig. 3. Relationship between drying rate and moisture ratio for convective drying

and for combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C)

kg/kg db and VMFD at microwave power 240, 360 or 480 W).

75

77

79

81

83

85

87

0.05

0.1

0.15

0.2

50

55

60

65

70

75

80

85

90

0.05

0.25

0.45

0.65

0.85

1.05

Moisture content (kg/kg db)

T

emper

ature (

o

C)

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

Fig. 4. Temperature profile for beetroot cubes during VMFD at microwave power

240, 360 or 480 W, after CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/

kg db.

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

465

material. Namely, non uniform distribution of dry mass and water

within particular beetroot cubes of dissimilar cellular structure

caused that the volume of these cubes underwent changes at dif-

ferent rate during drying. However, during convective drying oc-

curred structural collapse due to water loss, whereas during

VMFD arose volume expansion as the result of the puffing. Never-

theless, the values of statistical estimators such as R

2

and FSE com-

piled in

1 indicate that the decrease in moisture content

increased V

R

of VMFD samples and decreased V

R

of samples dried

by convection, with the satisfactory linear correlation:

V

R

¼ a M þ b

ð11Þ

The values of parameters a and b of Eq.

are compiled in

. Reduced shrinkage of VM treated beetroot cubes, due to the

puffing phenomenon, was confirmed in the case of apples (

) and other biological materials such as mint leafs

(

), carrots (

) and tomatoes

(

).

Both, increasing the microwave wattage and decreasing the

time of CPD increased V

R

of cubes dehydrated by the combined

method and, consequently, decreased their shrinkage. However,

comparing V

R

of the samples with lowest moisture content, only

the cubes minimally pre-dried (V

R

= 0.4 m

3

/m

3

), as well as VMFD

at highest microwave wattage (V

R

= 0.38 m

3

/m

3

), differed signifi-

cantly from other VM treated ones (V

R

= 0.32 0.35 m

3

/m

3

). The

V

R

value of samples dried by convection was radically lower,

amounting to 0.23 m

3

/m

3

. The positive effect of microwave watt-

age on shrinkage reduction was also observed during VM drying

of garlic (

). The increase in V

R

caused by decreasing

time of convective pre-drying is associated with softness of the cel-

lular structure of the material. At longer convective pre-drying the

structure is less soft and local hardening occurs more often (

). This makes puffing difficult.

showed that proper moisture content obtained by CPD and rela-

tively high microwave power during following VM drying could in-

crease the expansion ratio and in this way improve the texture of

the finished product. This expansion ratio depends on the stiffness

of the material undergoing the dual mechanism of the puffing phe-

nomenon that consists in internal overpressure of the trapped air

in relation to external vacuum and generation of vapour due to

the internal temperature rise (

).

It was found that all beetroot samples were puffed during

VMFD despite of their current moisture content. After taking them

out of the dryer the effect of puffing diminished under ambient

pressure. The decreased moisture content enlarged rigidity of

cellular walls preventing structural collapse and in this way fixing

the effect of puffing (

). The stiffness of cellular walls is

associated with compressive strength of an entire cube.

3.4. Compressive strength

The decrease in moisture content increased the breaking stress

) according to the exponential equation:

r

max

¼ a e

M

b

ð12Þ

The values of parameters a and b are compiled in

. It was

found that the intensive increase in

r

max

started beyond the critical

moisture content, i.e. in that range where temperature of VMFD

samples was decreasing due to lowering of the amount of water

responsible for generation of heat energy. It was also found that

standard deviation on mean values of

r

max

, acceptable until the

critical point, considerably increased beyond this point. This

behaviour can be explained by the plasticization effect of water

on the anisotropic structure of biological material being dried.

Namely, until the critical point was reached the amount of water

was enough to ensure a plastic deformation of beetroot cubes until

breaking under the high internal pressure created by compression.

This pressure, distributed uniformly enough within the whole vol-

ume of the cube due to yet elastic cellular walls, ensured compara-

ble breaking stress. Beyond the critical point the amount of water

was to small to act as a plasticizer for the non homogenous struc-

ture which became unequally rigid in different regions of a partic-

ular beetroot cube dehydrated under the same drying conditions.

For this reason, breaking of the cubes was initiated locally under

considerably different stress.

Definitely, the highest compressive strength exhibited samples

dried by convection, while the lowest one was found for FD sam-

ple. Among VMFD samples a significantly softer texture exhibited

those dehydrated with highest microwave power and samples

minimally pre-dried. The values of

r

max

ranged from 0.55 to

2.14 MPa for FD cubes and cubes maximally dehydrated by con-

vection, respectively. Then, VMFD sample maximally dehydrated

at 480 W underwent breaking under 0.89 MPa.

claimed that VM dried and particularly FD carrot slices exhibited

much softer texture than samples dried by convection.

There is a relationship between compressive strength and

shrinkage of dehydrated beetroot cubes. Namely, lower shrinkage,

occurring at higher V

R

, favoured obtaining lower values of

r

max

.

The same relationship between shrinkage and resistance of apple

slices dried in hot air to compression was reported by

0.2

0.25

0.3

0.35

0.4

0.45

0.05

0.07

0.09

0.11

0.13

0.15

0.17

0.19

Moisture content (kg/kg db)

Relativ

e v

olume (m

3

/m

3

)

Convection

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

Fig. 5. Relative volume of beetroot cubes dehydrated by convection and by

combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/kg db

and VMFD at microwave power 240, 360 or 480 W).

0

0.5

1

1.5

2

2.5

0.05

0.07

0.09

0.11

0.13

0.15

Moisture content (kg/kg db)

Breaking stress (MP

a)

Convection

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

FD

Fig. 6. Breaking stress of beetroot cubes dehydrated by FD, convection and by

combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/kg db

and VMFD at microwave power 240, 360 or 480 W).

466

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

. The more puffed structure, in the case of

VMFD samples or rich in pores in the case of FD ones, is more sus-

ceptible to local cracking and yield under compressive load than

the shrunk structure with a smaller number of pores, such as the

one obtained with convection.

proved that

the force required to cause an assumed deformation was higher

for convectively dried potato cubes than for VM dried ones.

Lower

r

max

values made dried product more prone to damages

during storage or handling operations, though simultaneously en-

sured soft texture which is usually more preferable by potential

consumers than hard texture (

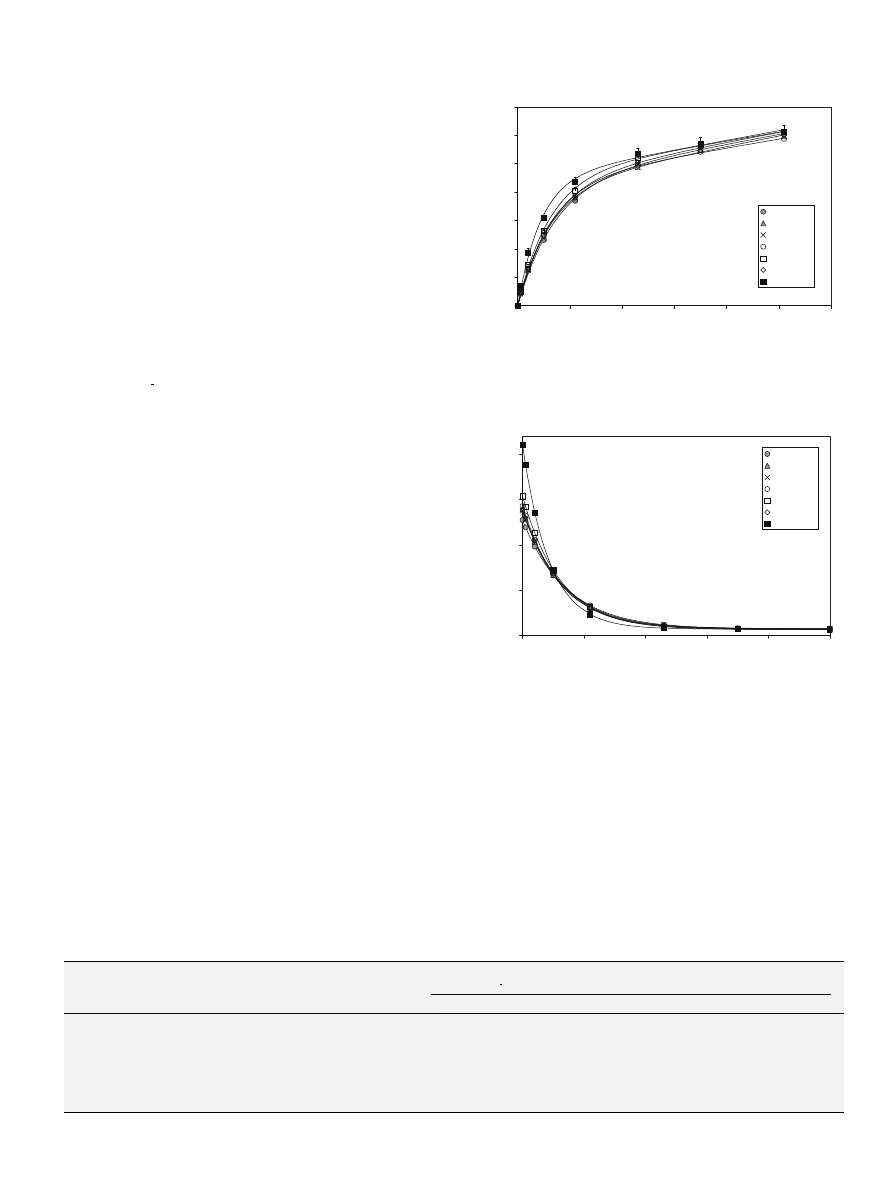

3.5. Water absorption

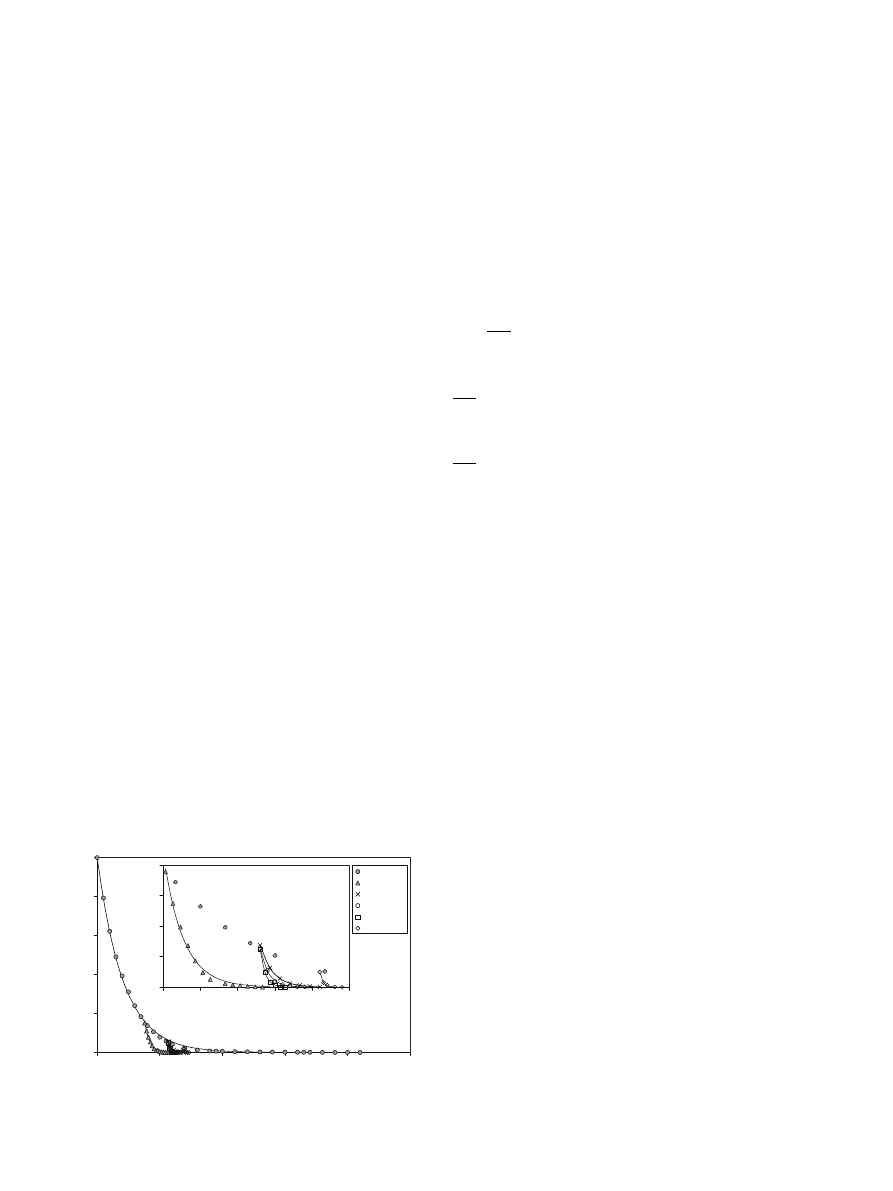

The absorption capacity AC of water vapour determined for

beetroot cubes placed in environmental chamber was described

by the two term equation:

AC ¼ a ð1 e

t

b

Þ þ c t

ð13Þ

Parameters a, b and c of Eq.

are compiled in

. The

form of this equation and the shape of the water absorption curve

(

) revealed that rehydration of beetroot cubes was not com-

pleted within 50 h of the test. Nevertheless, the test duration

was long enough to show the difference in water absorption kinet-

ics for samples dried under different conditions. The highest values

of AC were found for FD sample. High AC potential was also stated

for VMFD samples dehydrated at the highest microwave power. AC

determined for other samples was lower up to 24 h of the test. Be-

yond that time the difference was not statistically significant de-

spite the relatively low standard deviation, which did not exceed

4% of AC mean value. At the end of the rehydration test the highest

AC, amounting to 0.122 kg/kg, was found for FD cubes and VMFD

ones dehydrated at 480 W. FD samples usually exhibited excellent

rehydration properties (

). These properties were also

improved by application of high microwave powers in the case of

microwave-convection dehydrated carrot cubes

) or mushrooms

). Apparently, the structure of products

dehydrated with application of high microwave wattage facilities

rehydration process. The main attributes of this structure created

in beetroot cubes by VMFD at 480 W was satisfactory V

R

and low compressive strength (

).

The differentiation of Eq.

enabled AC rate (AC

R

) estimation

). At the very beginning of the rehydration test the highest

AC

R

was found for FD sample (0.021 kg/kg/h) while the lowest

one for convective dried sample (0.013 kg/kg/h). The differences

in AC

R

diminished in time for 6 h of the test when all the samples

exhibited similar AC

R

equal to 0.07 kg/kg/h. After that time the de-

crease in AC

R

was approximately the same for all samples except

the FD one. Namely, AC

R

for this sample was the lowest for the next

20 h until the moment when almost a constant value of parameter

c was reached. This parameter is also the tangent of the slope angle

of the asymptote, which determines the increase in AC at the final

stage of the test. Parameter a is the maximum value which can be

attained by the first term in Eq.

. Parameter b is a retardation

time, after which the first term of this equation reaches 63% of a

value (

) The sum of both parameters a and c gives

the value of AC at the end of rehydration.

Table 2

Values of the parameters a, b and c of the function describing the absorption capacity of beetroot samples.

Drying method

CPD level (kg/kg db)

MP (W)

Absorption capacity

AC ¼ a ð1 e

t

b

Þ þ c t

a

b

c

R

2

FSE

CPD–VMFD

1.6

360

0.0826

6.27

738 10

6

0.9992

1.516 10

3

0.6

240

0.0871

6.66

700 10

6

0.9992

1.629 10

3

0.6

360

0.0860

6.29

627 10

6

0.9994

1.293 10

3

0.6

480

0.0913

6.18

618 10

6

0.9989

1.886 10

3

0.27

360

0.0869

6.54

656 10

6

0.9991

1.667 10

3

Convection

0.0866

7.17

681 10

6

0.9989

1.857 10

3

Freeze-drying

0.0891

4.37

683 10

6

0.9971

2.990 10

3

CPD = convective pre-drying, VMFD = vacuum-microwave finish drying, MP = microwave power, R

2

= coefficient of determination, FSE = fit standard error.

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0

10

20

30

40

50

60

Time (hours)

Absor

ption capacity (kg/kg)

Convection

A, 360W

B, 240W

B, 360W

B, 480W

C, 360W

FD

Fig. 7. Absorption capacity of beetroot cubes dehydrated by FD, convection and by

combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/kg db

and VMFD at microwave power 240, 360 or 480 W).

0

0.005

0.01

0.015

0.02

0

10

20

30

40

50

Time (hours)

Absor

ption capacity r

ate (kg/kg/h)

Convection

A, 360 W

B, 240 W

B, 360 W

B, 480 W

C, 360 W

FD

Fig. 8. Absorption capacity rate of beetroot cubes dehydrated by FD, convection and

by combined method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/

kg db and VMFD at microwave power 240, 360 or 480 W).

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

467

3.6. Colour

The results of colour measurement (

) showed that dur-

ing drying beetroot cubes the parameters L

*

, a

*

and b

*

were increas-

ing considerably in the falling temperature period. Almost all

values of these parameters determined for the most dehydrated

samples differed significantly from the ones of higher moisture

content obtained under the same drying conditions These values,

obtained under the same drying conditions, are compiled in sepa-

rate blocks in

. The last two values in each block usually be-

longed to the same homogenous group (Duncan test, p < 0.05). It

means that the presence of water and the temperature profile have

a decisive effect on the colour of the biological product subjected to

drying. Comparing the most dehydrated samples under particular

drying conditions, the significantly highest values of L

*

and a

*

were

found for FD beetroot cubes (28.71 and 35.53, respectively), VMFD

cubes maximally pre-dried by convective method (29.00 and

33.80, respectively) or cubes dried only by convection (27.84 and

34.68, respectively), while the lowest ones for cubes minimally

pre-dried by convective method (23.38 and 30.51, respectively).

It is worth noting that FD cubes had the lowest moisture content,

which enhanced the obtained higher values of the colour parame-

ters. However, high values of L

*

and a

*

of samples maximally pre-

dried or dried by convection might result from Maillard reaction

that occurred at high temperature or was caused by long exposi-

tion to preheated air (

).

The value of b

*

was significantly the highest for the cubes max-

imally pre-dried (14.16) and the lowest for FD cubes (6.60). Low

values of b

*

belonging to the same homogenous group (Duncan

test, p < 0.05) were also found for samples minimally pre-dried

(8.76) and those dried only by convection (9.32).

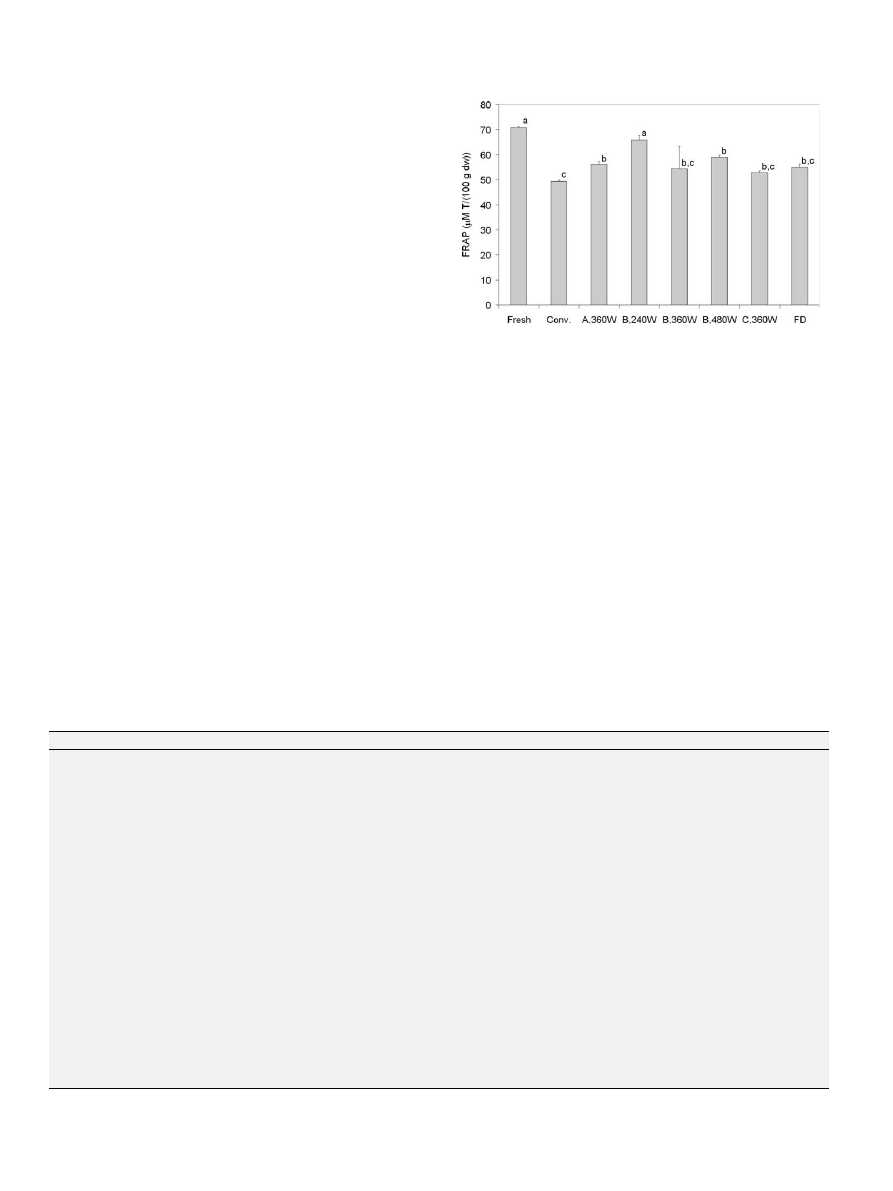

3.7. Antioxidant activity

The results of FRAP assay (

) showed that of all the pro-

cessed samples the highest antioxidant activity had beetroot cubes

dried by the combined method at 240 and 480 W (65.98 and

59.07

l

M T/100 g dw, respectively), while the lowest one was

found for cubes dried in convention (49.38

l

M T/100 g dw). Sam-

ples pre-dried to different moisture contents and then finish dried

at the same microwave power 360 W exhibited similar activity

that amounted to about 54.50

l

M T/100 g dw.

Those results could be affected by many complex factors. The

lowest antioxidant activity of samples dried by convection came

from intensive oxidation that occurred during their long exposition

to the hot air. The antioxidant activity of rosemary herb dried in

hot air was lower than for those dried by VM method (

). VMFD effectively limited this oxidation effect

mainly due to the lowered air pressure in the drying chamber.

The antioxidant activity of VMFD beetroot cubes was additionally

favoured by the relatively low temperature registered for the low-

est microwave power. However, application of higher microwave

Table 3

Values of the colour parameters L

*

, a

*

and b

*

of dehydrated beetroot samples.

Drying method

CPD level (kg/kg db)

MP (W)

M (kg/kg db)

L

*

a

*

b

*

CPD–VMFD

1.6

360

0.056

23.38 ± 0.45

a

y

30.51 ± 0.72

a

z

8.76 ± 0.12

a

y

0.058

20.01 ± 0.81

b

21.87 ± 0.78

b

4.62 ± 0.51

b

0.116

20.40 ± 0.37

b

23.76 ± 0.54

c

5.27 ± 0.15

b

0.6

240

0.066

25.42 ± 0.93

a

x

33.23 ± 0.84

a

wx

10.71 ± 0.67

a

x

0.069

21.80 ± 0.45

b

21.89 ± 0.25

b

4.82 ± 0.26

b

0.076

19.90 ± 0.58

c

22.75 ± 0.67

b

5.09 ± 0.37

b

0.108

20.45 ± 0.27

c

22.43 ± 0.17

b

5.55 ± 0.03

b

0.6

360

0.059

26.66 ± 0.67

a

wx

32.76 ± 0.98

a

xy

12.05 ± 0.76

a

w

0.060

20.17 ± 0.33

b

22.64 ± 0.84

b

5.94 ± 0.11

b

0.066

18.91 ± 0.18

c

21.54 ± 0.54

b

4.61 ± 0.13

c

0.113

20.12 ± 0.26

b

21.97 ± 0.51

b

5.18 ± 0.34

bc

0.6

480

0.059

26.52 ± 0.76

a

wx

31.45 ± 0.76

a

yz

11.64 ± 0.55

a

wx

0.060

24.74 ± 0.58

b

30.73 ± 1.10

a

10.83 ± 0.47

a

0.078

21.27 ± 1.02

c

21.68 ± 1.25

b

4.94 ± 0.36

b

0.118

19.70 ± 0.47

d

22.05 ± 1.02

b

5.01 ± 0.46

b

0.27

360

0.059

29.00 ± 0.94

a

u

33.80 ± 1.24

a

wx

14.16 ± 0.96

a

z

0.061

20.25 ± 0.50

b

22.08 ± 1.66

b

5.16 ± 0.45

b

0.098

21.01 ± 0.34

b

22.74 ± 0.39

b

5.20 ± 0.96

b

Convection

0.056

27.84 ± 0.81

a

uw

34.68 ± 0.73

a

uw

9.32 ± 0.23

a

y

0.058

22.31 ± 1.01

b

24.25 ± 0.83

b

5.31 ± 0.40

b

0.072

19.61 ± 0.75

c

22.57 ± 1.05

c

5.06 ± 0.25

b

0.095

19.95 ± 0.38

c

21.12 ± 0.58

c

4.14 ± 0.25

c

Freeze-drying

0.054

28.71 ± 0.16

u

35.53 ± 0.49

u

6.60 ± 0.15

u

CPD = convective pre-drying, VMFD = vacuum-microwave finish drying, MP = microwave power, M = moisture content.

Different superscripts (u, w, x, y, z) indicate significant differences between values obtained for the most dehydrated samples at particular drying conditions and different

subscripts (a, b, c) indicate significant differences between values obtained for the samples dehydrated at the same drying conditions (Duncan test, p < 0.05).

Fig. 9. Antioxidant activity measured by FRAP assay in fresh beetroot cubes and

those dehydrated by convection (Conv.), freeze-drying (FD) as well as the combined

method (CPD until moisture contents: 1.6 (A), 0.6 (B) or 0.27 (C) kg/kg db and VMFD

at microwave power 240, 360 or 480 W). Different letters (a, b, c) at bars indicate

significant differences between values (Duncan test, p < 0.05).

468

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

power decreased the time of VMFD and in this way could reduce

thermal degradation of the compounds responsible for antioxidant

activity of these cubes. The increase in microwave power during

VM drying of oregano increased the antioxidant activity of dried

product (

). Astonishingly high antioxidant

activity of VMFD beetroot cubes, in relation to FD ones, confirmed

by the result obtained when drying blueberries (

and strawberries (

), could be caused by the

Maillard reaction, which creates various products named Maillard

reaction products (MRPs), which have higher antioxidant power

than their precursors (

). Therefore, it can

be assumed that the high antioxidant activity of VMFD beetroot

cubes are attributed to MRPs. However,

claimed

that the increase in antioxidant capacity due to MRPs may not

compensate for the destruction of phenolic compounds. The mech-

anism of antioxidant activity alteration during combined drying of

beetroots needs yet more consideration.

4. Conclusions

The total time of combined drying of beetroot cubes can be con-

siderably shortened by an early introduction of VMFD at high

microwave wattage. However, the drying rate is enhanced not only

by increasing the microwave power, but also by lengthening the

CPD. The course of beetroot temperature during VMFD undergoes

a change at critical moisture content, exhibiting both increasing

and falling periods. The existence of a critical moisture content

might be explained by the thermal balance between the energy

generated by water dipoles and energy necessary for water evapo-

ration to the ambient of lower temperature. The decrease in the

amount of water has a decisive effect on the colour of beetroots

subjected to drying within the falling temperature period. Increas-

ing the microwave wattage and decreasing the time of CPD de-

creases both the shrinkage and breaking stress of beetroot cubes.

The rehydration potential of such cubes can be improved by appli-

cation of high microwave wattage. The CPD–VMFD method offers

product of high antioxidant activity comparable to that obtained

by FD. The final conclusion is that an early introduction of VMFD

at high microwave wattage during combined drying may guaran-

tee high quality of biological material dehydrated by the combined

method comparable with the quality ensured by FD.

Acknowledgements

This work was supported by the Polish Ministry of Science and

Higher Education under Grant No. N312 031 32/2036 in years

2007–2009.

References

Andres, A., Bilbao, K., Fito, P., 2004. Drying kinetics of apple cylinders under

combined hot air–microwave dehydration. Journal of Food Engineering 63, 71–

78.

Aro, A., Amaral, E., Kesteloot, H., Rimestad, A., Thamm, M., van Poppel, G., 1998.

Trans fatty acids in French fries, soups, and snacks from 14 European countries:

the transfair study. Journal of Food Composition and Analysis 11, 170–177.

Atamanova, A., Brezhneva, T.A., Slivkin, A.I., Nikolaevskii, V.A., Selemenev, V.F.,

Mironenko, N.V., 2005. Isolation of saponins from table beetroot and primary

evaluation of their pharmacological activity. Pharmaceutical Chemistry Journal

39 (12), 650–652.

Benzie, I.F.F., Strain, J.J., 1996. The ferric reducing ability of plasma (FRAP) as a

measure of ‘‘antioxidant power”: the FRAP assay. Analytical Biochemistry 239,

70–76.

Böhm, V., Kühnert, S., Rohm, H., Scholze, G., 2006. Improving the nutritional quality

of microwave-vacuum dried strawberries: a preliminary study. Food Science

and Technology International 12, 67–75.

Bondaruk, J., Markowski, M., Błaszczak, W., 2007. Effect of drying conditions on the

quality of vacuum-microwave dried potato cubes. Journal of Food Engineering

81, 306–312.

Chua, K.J., Mujumdar, A.S., Hawlader, M.N.A., Chou, S.K., Ho, J.C., 2001. Batch drying

of banana pieces – effect of stepwise change in drying air temperature on drying

kinetics and product colour. Food Research International 34, 721–731.

Cui, Z.W., Xu, S.Y., Sun, D.W., 2003. Dehydration of garlic slices by combined

microwave-vacuum and air drying. Drying Technology 21 (7), 1173–1184.

Cui, Z.W., Xu, S.Y., Sun, D.W., 2004. Microwave-vacuum drying kinetics of carrot

slices. Journal of Food Engineering 65, 154–164.

Delwiche, S.R., Pearson, J.L., Sanders, T.H., Wilson, D.M., Shupe, W.L., 1986.

Microwave vacuum drying effect on peanut quality. Peanut Science 13 (1),

21–27.

de Zwart, F.J., Slow, S., Payne, R.J., Lever, M., George, P.M., Gerrard, J.A., Chambers,

S.T., 2003. Glycine betaine and glycine betaine analogues in common foods.

Food Chemistry 83, 197–204.

Dias, M.G., Cam}

oes, M.F.G.F.C., Oliveira, L., 2009. Carotenoids in traditional

Portuguese fruits and vegetables. Food Chemistry 113, 808–815.

Drouzas, A.E., Schubert, H., 1996. Microwave application in vacuum drying of fruits.

Journal of Food Engineering 28, 203–209.

Durance, T.D., Wang, J.H., 2002. Energy consumption, density, and rehydration rate

of vacuum-microwave and hot-air convection-dehydrated tomatoes. Journal of

Food Science 67 (6), 2212–2216.

Figiel, A., 2006. Drying kinetics and drying shrinkage of garlic subjected to vacuum-

microwave dehydration. Acta Agrophysica 7 (1), 49–58.

Figiel, A., 2007. Dehydration of apples by a combination of convective and vacuum-

microwave drying. Polish Journal of Food and Nutrition Sciences 57 (4A), 131–

135.

Figiel, A., 2009. Drying kinetics and quality of vacuum-microwave dehydrated garlic

cloves and slices. Journal of Food Engineering 94, 98–104.

Figiel, A., Wojdyło, A., Juszczyk, P., Carbonell-Barrachina, A., 2008. Drying of pears

by a combination of convective and vacuum-microwave methods. In:

Proceedings of the 16th International Drying Symposium, Hyderabad, India.

Giri, S.K., Prasad, S., 2007. Drying kinetics and rehydration characteristics of

microwave-vacuum and convective hot-air dried mushrooms. Journal of Food

Engineering 78, 512–521.

Gutiérrez-Ortiz, A., Figiel, A., Wojdyło, A., Juszczyk, P., Vázquez-Araújo, L.,

Carbonell-Barrachina, A.A., 2008. Drying of rosemary herb by a combination

of convective and vacuum-microwave methods. In: Proceedings of the II

Congreso Iberoamericano Sobre Seguridad Alimentaria, Barcelona, Spain (in

Spanish).

Hu, Q.G., Zhang, M., Mujumdar, A.S., Xiao, G.N., Sun, J.C., 2006. Drying of edamames

by hot air and vacuum microwave combination. Journal of Food Engineering 77,

977–982.

Jałoszyn´ski, K., Figiel, A., Wojdyło, A., 2008. Drying kinetics and antioxidant activity

of oregano. Acta Agrophysica 11 (1), 81–90.

Jastrebova, J., Witthoft, C., Grahn, A., Svensson, U., Jagerstad, M., 2003. HPLC

determination of folates in raw and processed beetroots. Food Chemistry 80,

579–588.

Kamin´ski, W., Tomczak, E., Skorupska, E., 2004. Estimation of the effect of shape and

temperature on drying kinetics using MLP. Drying Technology 22 (1 and 2),

191–200.

Kapadia, G.J., Tokuda, H., Konoshima, T., Nishino, H., 1996. Chemoprevention of lung

and skin cancer by Beta vulgaris (beet) root extract. Cancer Letters 100, 211–

214.

Khraisheh, M.A.M., McMinn, W.A.M., Magee, T.R.A., 2004. Quality and structural

changes in starchy foods during microwave and convective drying. Food

Research International 37, 497–503.

Krejcova, A., Cernohorsky, T., Meixner, D., 2007. Elemental analysis of instant soups

and seasoning mixtures by ICP–OES. Food Chemistry 105, 242–247.

Krulis, M., Kuhnert, S., Leiker, M., Rohm, H., 2005. Influence of energy input and

initial

moisture

on

physical

properties

of

microwave-vacuum

dried

strawberries. European Food Research Technology 221, 803–808.

Le Loch-Bonazzi, C., Wolff, E., Gilbert, H., 1992. Quality of dehydrated cultivated

mushrooms (Agaricus bisporus): a comparison between different drying and

freeze-drying processes. Lebensmittel-Wissenschaft und -Technologie 25, 334–

339.

Lewicki, P.P., 1998. Some remarks on rehydration of dried foods. Journal of Food

Engineering 36, 81–87.

Lewicki, P.P., 2006. Design of hot air drying for better foods. Trends in Food Science

and Technology 17, 153–163.

Lewicki, P.P., Jakubczyk, E., 2004. Effect of hot air temperature on mechanical

properties of dried apples. Journal of Food Engineering 64, 307–314.

Lin, T.M., Durance, T.D., Scaman, C.H., 1998. Characterization of vacuum microwave,

air and freeze dried carrot slices. Food Research International 31 (2), 111–117.

Marfil, P.H.M., Santos, E.M., Telis, V.R.N., 2008. Ascorbic acid degradation kinetics in

tomatoes at different drying conditions. LWT-Food Science and Technology 41,

1642–1647.

Maskan, M., 2000. Microwave/air and microwave finish drying of banana. Journal of

Food Engineering 44, 71–78.

Maskan, M., 2001. Kinetics of colour change of kiwifruits during hot air and

microwave drying. Journal of Food Engineering 48, 169–175.

Mathlouthi, M., 2001. Water content, water activity, water structure and the

stability of foodstuffs. Food Control 12, 409–417.

Mayor, L., Sereno, A.M., 2004. Modeling shrinkage during convective drying of food

materials: a review. Journal of Food Engineering 61, 373–386.

Men’shutina, N.V., Gordienko, M.G., Voinovskii, A.A., Kudra, T., 2005. Dynamic

criteria for evaluating the energy consumption efficiency of drying equipment.

Theoretical Foundations of Chemical Engineering 39 (2), 158–162.

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

469

Mousa, N., Farid, M., 2002. Microwave vacuum drying of banana slices. Drying

Technology 20, 2055–2066.

Nawirska, A., Figiel, A., Kucharska, A.Z., Sokół-Łe˛towska, A., Biesiada, A., 2009.

Drying kinetics and quality parameters of pumpkin slices dehydrated using

different methods. Journal of Food Engineering 94, 14–20.

Patkai, G., Barta, J., Varsanyi, I., 1997. Decomposition of anticarcinogen factors of the

beetroot during juice and nectar production. Cancer Letters 114, 105–106.

Piga, A., Del Caro, A., Corda, G., 2003. From plums to prunes: influence of drying

parameters on polyphenols and antioxidant activity. Journal of Agricultural and

Food Chemistry 51, 3675–3681.

Prabhanjan, D.G., Ramaswamy, H.S., Raghavan, G.S.V., 1995. Microwave-assisted

convective air drying of thin layer carrots. Journal of Food Engineering 25, 283–

293.

Rahman, S., 1999. Handbook of Food Preservation. Marcel Dekker, New York, Basel.

Ressing, H., Ressing, M., Durance, T., 2007. Modeling the mechanisms of dough

puffing during vacuum microwave drying using the finite element method.

Journal of Food Engineering 82, 498–508.

Roberts, J.S., Tong, C.H., Lund, D.B., 2002. Drying kinetics and time–temperature

distribution of pregelatinized bread. Journal of Food Science 67 (3), 1080–1087.

Sham, P.W.Y., Scaman, C.H., Durance, T.D., 2001. Texture of vacuum microwave

dehydrated apple chips as affected by calcium pretreatment, vacuum level, and

apple variety. Journal of Food Science 66 (9), 1341–1347.

Sharma, G.P., Prasad, S., 2004. Effective moisture diffusivity of garlic cloves

undergoing microwave-convective drying. Journal of Food Engineering 65,

609–617.

Shynkaryk, M.V., Lebovka, N.I., Vorobiev, E., 2008. Pulsed electric fields and

temperature effects on drying and rehydration of red beetroots. Drying

Technology 26 (6), 695–704.

Sitkei, G., 1986. Mechanics of Agricultural Materials. Elsevier Applied Science,

Amsterdam, Oxford, New York, Tokyo.

Sjöholm, I., Gekas, V., 1995. Apple shrinkage upon drying. Journal of Food

Engineering 25, 123–130.

Soysal, Y., Ayhan, Z., Esturk, O., Arıkan, M.F., 2009. Intermittent microwave-

convective drying of red pepper: drying kinetics, physical (colour and texture)

and sensory quality. Biosystems Engineering 103, 446–455.

Sunjka, P.S., Rennie, T.J., Beaudry, C., Raghavan, G.S.V., 2004. Microwave-convective

and microwave-vacuum drying of cranberries: a comparative study. Drying

Technology 22 (5), 1217–1231.

Szarycz, M., 2001. Mathematical modelling of microwave-convection drying of

agricultural raw material on the example of apples. Zeszyty Naukowe Akademii

Rolniczej we Wrocławiu 420, 2–79 (in Polish).

Szczesniak, A.S., Kahn, E.L., 1971. Consumer awareness of attitudes to food texture:

adults. Journal of Texture Studies 2, 280–295.

Tang, J., 2005. Dielectric properties of foods. In: Schubert, H., Regier, M. (Eds.), The

Microwave Processing of Foods. CRC Press LLC, Boca Raton, Boston, New York,

Washington, DC, pp. 22–40.

Therdthai, N., Zhou, W., 2009. Characterization of microwave vacuum drying and

hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). Journal of Food

Engineering 91, 482–489.

Vaghri, Z., Scaman, C.H., Kitts, D.D, Durance, T.D., McArthur, D.A.J., 2000. Quality of

the vacuum microwave dried blueberries in terms of color, composition, and

antioxidant activity. In: Proceedings of the 12th International Drying

Symposium, Amsterdam, The Netherlands.

Váli, L., Stefanovits-Bányai, E., Szentmihályi, K., Fébel, H., Sárdi, E., Lugasi, A., Kocsis,

I., Blázovics, A., 2007. Liver-protecting effects of table beet (Beta vulgaris var.

Rubra) during ischemia-reperfusion. Nutrition 23, 172–178.

Wojdyło, A., Figiel, A., Oszmian´ski, J., 2009. Effect of drying methods with the

application of vacuum microwaves on the bioactive compounds, color and

antioxidant activity of strawberry fruits. Journal of Agricultural and Food

Chemistry 57, 1337–1343.

Yilmaz, Y., Toledo, R., 2005. Antioxidant activity of water-soluble Maillard reaction

products. Food Chemistry 93, 273–278.

Yongsawatdigul,

J.,

Gunasekaran,

S.,

1996.

Microwave-vacuum

drying

of

cranberries: part II. Quality evaluation. Journal of Food Processing and

Preservation 20, 145–156.

Zhang, J., Zhang, M., Shan, L., Fang, Z., 2007. Microwave-vacuum heating parameters

for processing savory crisp bighead carp (Hypophthalmichthys nobilis) slices.

Journal of Food Engineering 79, 885–891.

470

A. Figiel / Journal of Food Engineering 98 (2010) 461–470

Document Outline

- Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods

Wyszukiwarka

Podobne podstrony:

Drying kinetics and quality of vacuum microwave dehydrated garlic cloves and slices

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying kinetics and drying shrinkage of garlic subjected to vacuum microwave dehydration (Figiel)

Drying kinetics and quality of potato chips undergoing different drying techniques

Drying kinetics and rehydration characteristics of microwave vacuum and convective hot air dried mus

Dehydration of Carrots by a Combination of Freeze Drying, Microwave Heating and Air or Vacuum Drying

Experimental study of drying kinetics by forced convection of aromatic plants

Microwave Drying of Parsley Modelling, Kinetics, and Energy Aspects

Preparation of garlic powder with high allicin content by using combined microwave–vacuum and vacuum

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

Effect of Drying Techniques and Storage on Mulberry (Morus alba) Quality

Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit

Drying kinetics, water activity, shrinkage and texture of walnut kernels

Drying characteristics and drying quality of carrot using a two stage microwave process

Drying kinetics of apple cylinders under combined hot air–microwave dehydration

Desorption isotherm and heat pump drying kinetics of peas

Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying

Becker The quantity and quality of life and the evolution of world inequality

więcej podobnych podstron