Biosystems Engineering (2007) 96 (4), 495–502

doi:

10.1016/j.biosystemseng.2006.12.011

Energy Consumption and Colour Characteristics of Nettle Leaves during

Microwave, Vacuum and Convective Drying

Ilknur Alibas

Faculty of Agriculture, Department of Agricultural Machinery, Uludag University, 16059 Bursa, Turkey; e-mail:

(Received 27 March 2005; accepted in revised form 15 December 2006; published online 5 February 2007)

Nettle leaves (Urtica dioica L.) were dried from an initial moisture content of 441 to 01 (dry basis) by

involving microwave, convective and vacuum drying, respectively. Energy consumption and colour

parameters for the nettle leaves were compared at these different drying conditions. In particular, the

experiments were carried out at four different microwave power levels (500, 650, 750 and 850 W) and air

temperatures (50, 75, 100 and 125 1C) to investigate the effect of these factors on the microwave and

convective drying, respectively. Instead, under vacuum drying conditions both the influence of vacuum (20

and 50 mm [Hg]) and drying temperature (50 and 75 1C) were considered. Drying periods ranged from 4 to 6,

30 to 120 and 35 to 65 min for microwave, convective and vacuum drying, respectively. The semi-empirical

Page’s equation was able to reproduce the experimental drying curves at all operating conditions under

microwave, convective and vacuum drying. The optimum method with respect to the drying period, colour

and energy consumption was the microwave drying at 850 W.

r

2007 IAgrE. All rights reserved

Published by Elsevier Ltd

1. Introduction

Stinging nettle Urtica dioica L. belongs to the family

of Urticaceae. In the past few years, nettle has been

noted as a healing plant because of its considerable

effects on human health both in Turkey and in the other

countries all over the world (

). It is

considered to be a nutritive food. Nettle leaf has a long

history as an herbal remedy and nutritious addition to

the diet. The seeds and leaves of nettle contain minerals

(especially iron), vitamin C, pro-vitamin A (

), amino acids (

ascorbic acid (

Martinez-Para & Torija-Isasa, 1980

), rare

carbohydrates (

), and several

mineral elements (

). It is also known that

nettle has anti-oxidant, antimicrobial, anti-ulcer and

analgesic properties (

). Shoots of

nettle cooked as a potherb are added to soups and can

also be dried for winter use (

). Although the plants are used principally in

pottage, a tea made from the leaves has traditionally

been drunk (

).

Nettle is a vegetable which rapidly perishes after

harvest and which is currently consumed only in season.

Drying is the one of the storage methods, which has the

capability of extending the consumption period of

nettles, yet maintaining its nutrition content. Drying is

the process of removing the moisture in the product up

to certain threshold value by evaporation. In this way,

the product can be stored for a long period, since the

activities of the micro-organisms, enzymes or ferments

in the material are suppressed (

Different drying methods are used in the drying of

fruits and vegetables. Such as worsening of the taste,

colour and nutritional content of the product, decline in

the density and water absorbance capacity, as well as

shifting of the solutes from the internal part of the

drying material to the surface (

Yongsawatdigul & Gunesekaran, 1996

;

ARTICLE IN PRESS

1537-5110/$32.00

495

r

2007 IAgrE. All rights reserved

Published by Elsevier Ltd

;

).

The use of microwave rays in the drying of

agricultural products such as grains (

;

), vegetables (

;

and fruits (

;

;

) has become widespread

because it minimises the decline in food quality and

provides a rapid and an effective head distribution in the

material (

), which leads to energy

savings (

). Microwave drying creates an effect

for moisture transfer, leading to a water vapour pressure

gradient between the bulk and the surface of the

material, as in the convectional drying methods (

).

Microwave drying creates an effect for moisture

transfer, leading to a water vapour pressure gradient

between the bulk and the surface of the material, as in

the conventional drying methods (

Microwave energy applications in the drying of vege-

tables have several advantages including the shortening

of drying time, a homogenous energy distribution on the

material and, formation of suitable dry product

characteristics due to the increase in temperature in

the centre of the material. Among the other benefits of

using microwave drying are inhibition of high surface

temperatures, continuation of the product respiration,

lowered product temperatures when combined with

vacuum drying, reduction in the loss of water-soluble

components and energy savings (

).

Vacuum drying is a drying technique which is used for

drying of various products, retaining colour and vitamin

content (

). Vacuum enhances the

mass transfer because of an increased pressure gradient

between the inside and outside of the sample to dry and

maintains a low temperature level essential for thermo-

labile products (

). Better product

quality with respect to traits such as taste, flavour and

rehydration can be retained via high-degree vacuum

treatment (

). The key benefits

of vacuum drying include lower process temperatures,

less energy usage and hence greater energy efficiency,

improved drying rates, and in some cases, less shrinkage

of the product (

). Vacuum

drying has been successfully applied to many fruits and

vegetables and other heat-sensitive foods. Vacuum dried

materials are characterised by better quality retention of

nutrients and volatile aroma. However, the cost of the

process is high (

The objectives of this study were to: (i) evaluate the

efficacy of microwave, convective and vacuum drying

technique for nettle leaves; (ii) compare the measured

findings obtained during the drying of nettle with the

predicted values obtained with Page’s thin-layer drying

semi-empirical equation; (iii) determine the changes in

the colour values of the product after drying; and (iv)

determine the optimum drying method for the drying of

nettle, with respect to energy consumption, colour and

drying period.

2. Materials and methods

2.1. Drying experiments

The leaves used in the drying experiments were 25

(

7003) g in weight and were selected from healthy

plants of fresh nettle (Urtica dioica L.) provided from

Karacabey county of Bursa. All the samples were stored

at the temperature of 4

705 1C before being dried.

Fresh chard leaves were pre-treated in chamber of

steamy cooker (Raks Buharlim, Manisa, Turkey) before

drying to reduce enzymatic changes. In order to prevent

colour changes, the cooker was set to produce 100 1C

steam and the chard leaves were exposed to steam for

30 s.

Microwave and convective drying treatment was

performed in a domestic digital combine oven (Arcelik

MD 592, Turkey) with technical features of 230 V,

50 Hz and 2900 W. Microwave energy is capable of

polarising substances. The microwave oven has the

capability of operating at eight different microwave

stages, being 90, 160, 350, 500, 650, 750, 850 and

1000 W. The convective oven has the capability of

operating at nine different temperature stages, being 50,

75, 100, 125, 150, 175, 200, 225 and 250 1C at 1 m/s air

velocity. The area on which microwave and convective

drying is carried out was 327 mm by 370 mm by 207 mm

in size, and consisted of a rotating glass plate with

280 mm diameter at the base of the oven. Glass plate

rotates for 5 min

1

and the direction of 3601 rotation

can be changed by pressing the on/off button. Time

adjustment is done with the aid of a digital clock located

on the oven. The drying temperature of convective oven

can be reached after every weight measured within 5 s.

Vacuum drying treatment was performed in a

laboratory-type vacuum oven (Nuve EV 0180, Turkey)

with technical features of 220 V, 50 Hz, 35 A and

800 W. The temperature of vacuum oven has a

sensitivity of 1 1C, with a maximum temperature of

250 1C. The area on which vacuum drying is carried out

was 300 mm by 200 mm by 250 mm in size. An

analogous vacuum-meter which indicates the vacuum

value in terms of mm [Hg] exists on the vacuum oven.

Time adjustment is done with the aid of a program-

mable clock located on the oven.

ARTICLE IN PRESS

I. ALIBAS

496

Drying experiments were conducted using three

different drying methods, namely, microwave, convec-

tive and vacuum drying. Three different experimental

designs were performed for each method. Microwave

drying trial was carried out at four different microwave

generation powers being 850, 750, 650 and 500 W.

Convective drying trial was carried out at four different

temperatures being 50, 75, 100 and 125 1C. Four

different vacuum-temperature combinations were ob-

tained in vacuum trials by combining two different

vacuum levels i.e., 20 and 50 mm [Hg] and two different

temperature regimes at 50 and 75 1C, and the trials were

realised under the combinations of 50 1C–20 mm [Hg],

50 1C–50 mm [Hg], 75 1C–20 mm [Hg] and 75 1C–50 mm

[Hg]. A laboratory type greasy vacuum pump (Carpa-

nelli MMDE80B4, Italy) was used in the vacuum drying

with operating conditions were 220/240 V, 50/60 Hz

and 51/48 A. The vacuum pump is increased the least

vacuum value within 20 s.

All experiments were conducted at each drying

technique and the values obtained from these trials

were averaged and the drying parameters were deter-

mined. Dried nettle leaves which were being dried were

removed from the oven periodically (every 30 s for

microwave drying and every 5 min for vacuum and

convective drying) during the drying period, and the

moisture loss was determined by weighing the plate

using digital balance (Sartorious EX 2000A, Germany)

with 001 g precision (

). All

weighing processes were completed in 10 s during the

drying process. Energy consumption of microwave,

convective and vacuum oven with together vacuum

pump was determined using a digital electric counter

(Kaan, Type 101, Turkey) with 001 kW h precision.

Drying process continued until the moisture content of

nettle fell down to 01

70005 on dry basis.

2.2. Data analysis and empirical drying model

The following common semi-empirical Page’s equa-

tion [Eqn (1)] was used to describe the thin-layer drying

kinetics of nettle leaves (

M

R

¼

X X

e

X

0

X

e

¼

expððktÞ

n

Þ

,

(1)

where: M

R

is the moisture content ratio; X is the

moisture content at any drying time dry basis (db); X

e

is

the equilibrium moisture content % db; X

o

is the initial

moisture content in % db; t is the drying time in min; k

is the drying constant in min

1

; and n is the dimension-

less exponent.

2.3. Colour parameters

Leaf colour was determined by two readings on the

two different symmetrical faces of the leaf in each

replicate, using a Minolta CR 300 colorimeter (Konica-

Minolta, Osaka, Japan), calibrated with a white

standard

tile.

The

colour

brightness

coordinate

L measures the whiteness value of a colour and ranges

from black at 0 to white at 100. The chromaticity

coordinate a measures red when positive and green

when

negative,

and

the

chromaticity

coordinate

b measures yellow when positive and blue when

negative. Also, the chroma C [Eqn (2)] and hue angle

a [Eqn (3)] were calculated from the values for L, a, b

and used to describe the colour change during drying

(

):

C ¼

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

a

2

þ

b

2

p

(2)

a ¼ tan

1

ð

b=aÞ

(3)

2.4. Data analysis

The research was conducted using randomised plots

factorial experimental design. Determination of the

investigated components was carried out in three

replicates. Mean differences were tested for signifi-

cance by using an least significant difference (LSD)

(MSTATC) test at 1% level of significance.

Non-linear regression analysis was performed using

NLREG (NLREG version 63) to estimate the para-

meters k and n of semi-empirical Page’s equation [Eqn

(1)]. Regression results include the coefficients for the

equation and coefficient of determination R

2

.

3. Results and discussion

3.1. Drying curves

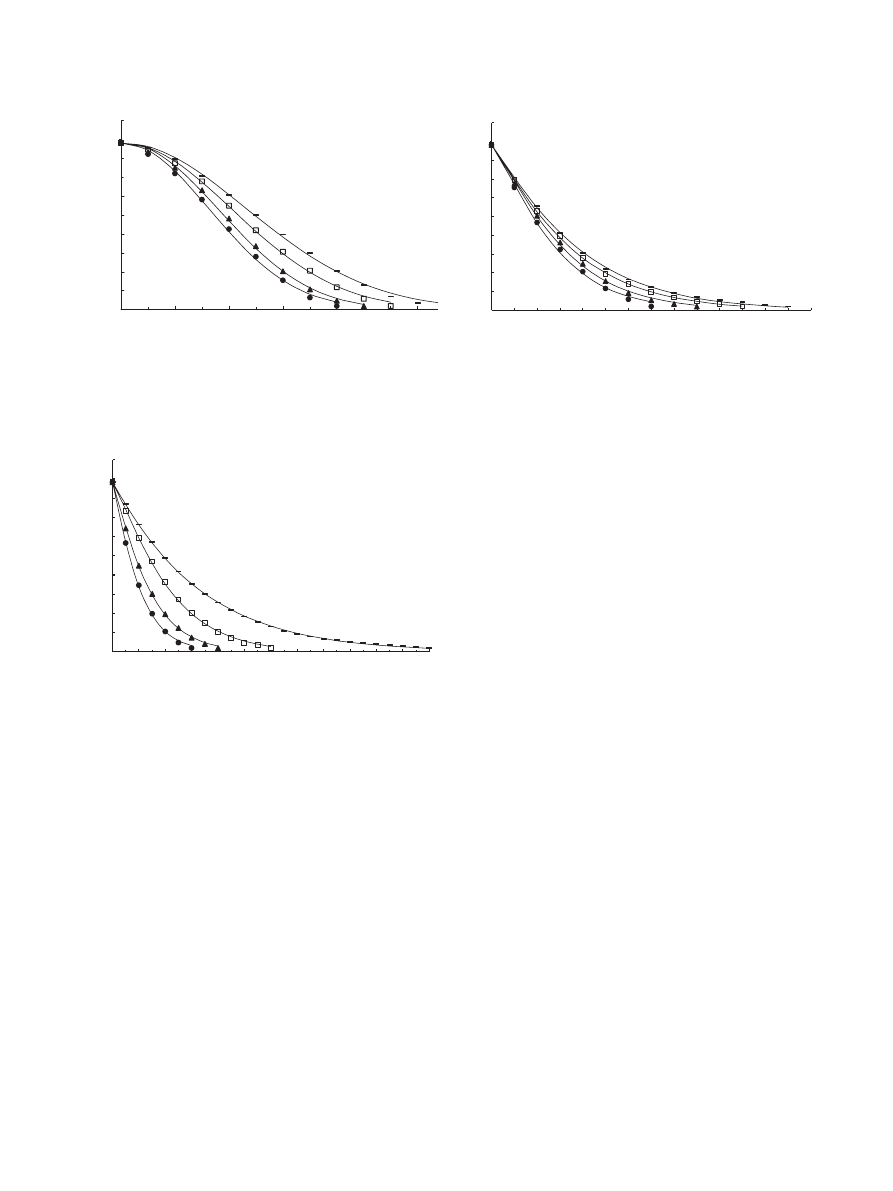

Moisture–time diagram of nettle along the drying

period on dry basis is given in

for microwave,

convective and vacuum drying, respectively.

A reduction in drying time occurred with increasing

the microwave power level. The time required for the

lowering of moisture content of nettle leaves to 01 from

441 on dry basis varied between 4 and 6 min depending

on the microwave power level. A marked decline was

noted in the drying period of leaves with the increasing

microwave power level (

). The required time for microwave drying

ARTICLE IN PRESS

ENERGY CONSUMPTION AND COLOUR CHARACTERISTICS OF NETTLE LEAVES

497

at 500 W was 15 times longer than that at 850 W. The

drying time reduced by 30 and 15 times in the drying

treatment realised at 50 and 75 1C temperatures and at 1

m/s air velocity compared with the drying treatment

realised at 850 W microwave powers. The moisture

content of the material was very high during the initial

phase of the drying which resulted in a higher

absorption of microwave power and higher drying rates

due to the higher moisture diffusion. As the drying

progressed, the loss of moisture in the product caused a

decrease in the absorption of microwave power and

resulted in a fall in the drying rate. Higher drying rates

were obtained at higher microwave output powers.

Thus, the microwave output power had a crucial effect

on the drying rate (

).

The convective drying process which reduced the

nettle leaves moisture contents from 441 db to moisture

content of 010 db took 30–120 min, depending on the

applied temperature. As the temperature was increased,

the drying time of leaves was significantly reduced

probability (P

o001) (

;

Mwithiga &

). By working at

125 1C instead of 50 1C, the drying time up to the

moisture content of 010 db could be shortened by 75%.

A marked decline was observed in the drying period

of nettle leaves with the increasing temperature level and

decreasing vacuum level (

).

Drying time at 50 1C temperature was found as 55 and

65 min for 20 and 50 mm [Hg], respectively, and at 75 1C,

it was found as 35 and 45 min for 20 and 50 mm [Hg]

vacuum values, respectively. Increase in temperature

level in vacuum drying had an important effect on the

reduction of drying time. The extent of drying realised at

50 1C temperature and 50 mm [Hg] vacuum value with

the longest drying period was 186 times higher

compared with the drying process realised at 75 1C and

20 mm [Hg], with the shortest drying period. When the

drying process realised at 50 1C temperature and 1m/s

air velocity without vacuum effect was compared with

the drying processes at 50 1C temperature and with 20

and 50 mm [Hg] vacuum values, the drying period was

shortened by 218 and 185 times, respectively, com-

pared with the drying without vacuum effect. Similarly,

when the drying applications realised at 75 1C with 20

and 50 mm [Hg] vacuum values were compared with

drying process without vacuum at 75 1C and 1m/s air

velocity, the drying period was reduced by 171 and 133

times, respectively, under vacuum.

ARTICLE IN PRESS

0

1

2

3

4

5

0

10

20

30

40

50

60

70

80

90 100 110 120

Convective drying time, min

M

o

isture content,

db

Fig. 2. The convective drying curve of nettle leaves on dry basis;

comparing experimental curve with the predicted one (-) through

semi-empirical Page’s equation [Eqn (1)] for nettle leaves at

various temperatures; K, 125 1C; m, 100 1C; &, 75 1C;—,

50 1C

0

1

2

3

4

5

0

1

2

3

4

5

Microwave drying time, min

Moisture content, db

Fig. 1. The microwave drying curve of nettle leaves on dry basis;

comparing experimental curve with the predicted one (-) through

semi-empirical Page’s equation [Eqn (1)] for nettle leaves at

various microwave levels; K, 850 W; m, 750 W; &, 650 W;—,

500 W

0

1

2

3

4

5

0

10

20

30

40

50

60

70

Vacuum drying time, min

Moisture content, db

Fig. 3. The vacuum drying curve of nettle leaves on dry basis;

comparing experimental curve with the predicted one (-)

through semi-empirical Page’s equation [Eqn (1)] for nettle

leaves at various vacuum and temperature combinations; K,

75 1C and 20 mm [Hg]; m, 75 1C and 50 mm [Hg]; &, 50 1C

and 20 mm [Hg];—, 50 1C and 50 mm [Hg]

I. ALIBAS

498

During the drying of 50 g nettle leaves at three

different drying methods, a total of 3987 g of weight

loss occurred from each drying sample.

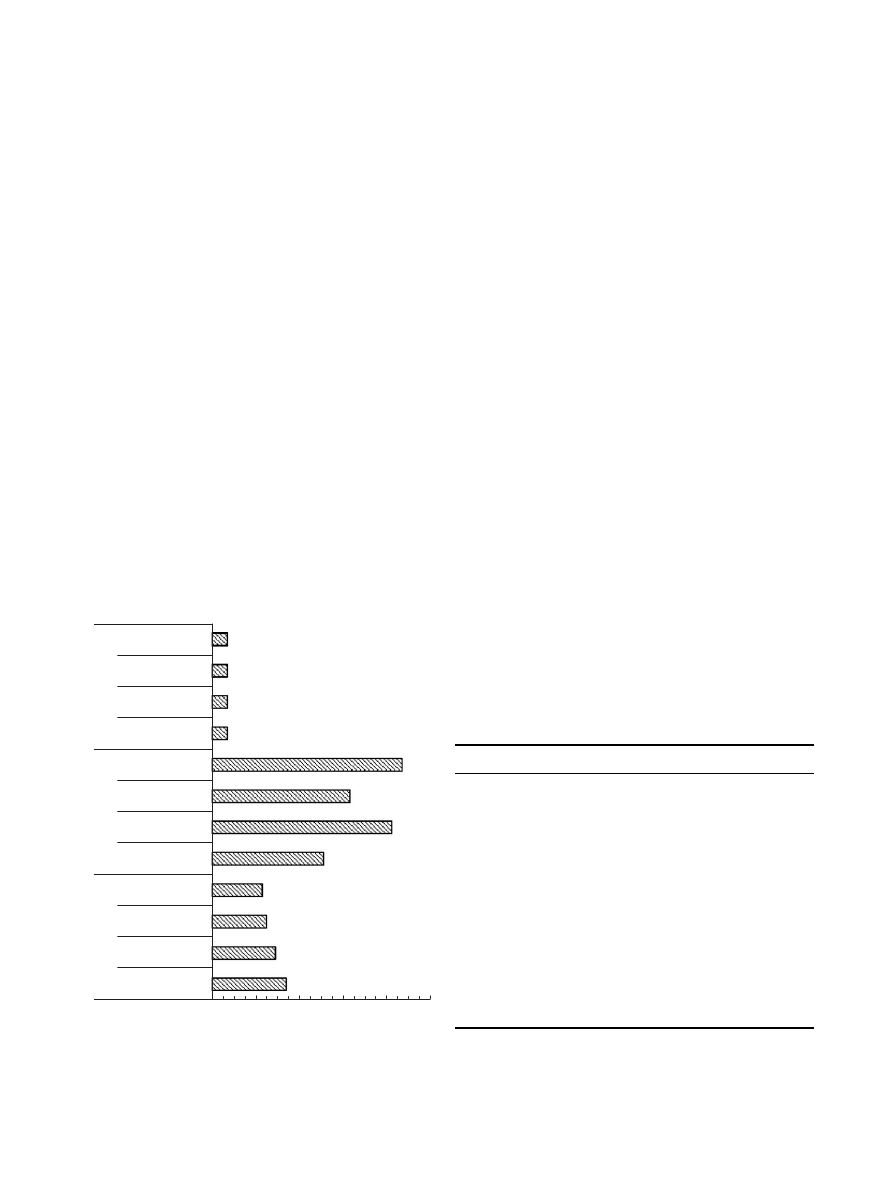

3.2. Energy consumption

The energy consumption values obtained during

microwave, convective and vacuum drying of nettle

leaves are given

. When the three drying methods

were compared with respect to energy consumption

values, it was noted that the lowest energy consumption

occurred in microwave drying method and this was

followed by convective- and vacuum- drying methods.

The best result with regard to energy consumption was

obtained from 850 W microwave levels among all drying

methods.

Energy

consumption

at

this

level

was

006 kW h. The highest value in all drying methods

regarding energy consumption was noted in vacuum

drying process consisting of 50 1C temperature and

50 mm [Hg] vacuuming rate, with 081 kW h. There was

a 135—fold difference between the highest (50 1C-

50 mm [Hg]) and the lowest (850 W) energy consump-

tion values.

3.3. Modelling drying data

The parameters k and n of a semi-empirical Page’s

thin layer drying equation [Eqn (1)] for a given

microwave, convective and vacuum drying condition

were estimated using non-linear regression technique

(

) and the fitness is illustrated in

respectively.

The model gave an excellent fit for all the experi-

mental data points with values for the coefficient of

determination of greater than 09982 at 850 W in

microwave drying, 09994 at 75 1C in convective drying

and 09976 (75 1C–20 mm [Hg]) in vacuum drying. It is

determined that the value of the drying constant k

increased with the increase in microwave power. This

data points out that following the increase in microwave

output power, drying curve becomes steeper, indicating

faster drying of the product. As a result, measured

moisture ratio values and predicted moisture ratio

values were found similar to each other (

). The drying constant k values

increased with the increasing temperature at all tem-

perature values but 75 1C (

The best coefficient of determination at 50 1C was 09999

at convective drying. The vacuum drying level estab-

lished by combining 50 1C temperature and 20 mm [Hg]

vacuuming rate gave the best result (09999) with respect

to coefficients of determination.

ARTICLE IN PRESS

0

0.8

0.6

0.4

0.2

1

50

°

C, 1 m/s

75

°

C, 1 m/s

100

°

C, 1 m/s

125

°

C, 1 m/s

20 mm[Hg], 75

°

C

20 mm[Hg], 50

°

C

50 mm[Hg], 75

°

C

50 mm[Hg], 50

°

C

500 W

650 W

750 W

850 W

Con

v

ecti

ve

V

acuum

Microw

ave

Energy consumption, kWh

Fig. 4. Energy consumption during the drying of nettle leaves at

three different drying methods

Table 1

Non-linear regression analysis results of semi-empirical Page’s

equation [Eqn (1)] for microwave, vacuum and convective drying

of nettle (

Urtica diocia L.) leaves; k, drying rate constant, min

1

;

n, exponent; SEE, standard error of estimate; R

2

, coefficient of

determination

Drying method

k

(NS)

n

SEE(

7)

(NS)

R

2(NS)

Microwave drying

850 W

01865

20276

001603

09982

750 W

01472

20911

001219

09990

650 W

01171

20335

001185

09990

500 W

00925

19988

001291

09988

Vacuum drying

75 1C–20 mm [Hg]

00373

12348

001721

09976

75 1C–50 mm [Hg]

00345

12155

001148

09989

50 1C–20 mm [Hg]

00368

11492

000396

09999

50 1C–50 mm [Hg]

00354

11302

000665

09996

Convective drying

50 1C

00697

11383

000841

09995

75 1C

00483

11520

000633

09997

100 1C

00251

12006

000826

09994

125 1C

00261

10446

000348

09999

Column mean values with different superscripts are significantly

different.

Probability Po001,

NS

not significant.

ENERGY CONSUMPTION AND COLOUR CHARACTERISTICS OF NETTLE LEAVES

499

3.4. Colour parameters

The colour parameters (L, a, b) formed in microwave,

convective and vacuum drying of nettle leaves are

compared in

The colour criteria obtained as a result of microwave

(500, 650, 750 and 850 W), convective (50, 75, 100 and

125 1C) and vacuum (50 1C–50 mm [Hg], 50 1C–20 mm

[Hg], 75 1C–50 mm [Hg] and 75 1C–20 mm [Hg]) drying

the nettle leaves, and the colour criteria obtained from

the fresh nettle leaves. An important loss was noted in

the values for L, a, and b of dried nettle leaves when

compared with fresh leaves.

The highest loss in brightness was determined in

500 W microwave power levels in microwave drying. A

higher value was obtained at 850 W in comparison with

the other power levels. Values similar to the results

obtained for L values were obtained with a, b values.

The colour values nearest to those of fresh nettle leaves

were reached in the drying applications made by using

850 W microwave powers. Similar results were obtained

by

. They examined the colour

change in carrot as influenced by 100, 300 and 500 W

microwave powers and determined the slightest colour

change in 500 W microwave output powers. According

to

, high moisture bio-products

undergoing microwave drying have the advantage.

Microwave drying removes the moisture on the surface

by converting it to water vapour; it results in drying

without causing surface overheating phenomena. There-

fore, in terms of surface colour degradation, preserva-

tion of the product colour was good. It is estimated that

the products are subjected to high temperature with the

increasing power levels during microwave drying (

). For this reason, the product colour is

also adversely affected, since the microwave drying

period is longer in the drying process realized at very

low microwave powers, and thus the product is

subjected to heat for a longer time (

). Also, in this study, the low values measured in L,

a, and b colour criteria measured at 500 W microwave

power are supported by the results in the previous

research given above.

The greatest loss in brightness was determined at 125 1C

temperature value in convective drying. Higher values

were obtained at 50 1C temperature compared with the

other treatments. Similar values were obtained also for a,

and b values. Colour values nearest to those of fresh nettle

leaves were reached with drying at 50 1C temperature.

examined the colour change in

red pepper at 50 and 60 1C; and determined the slightest

colour change at 50 1C temperature.

dried bay leaves at 40, 50 and 60 1C and obtained the best

colour value at 50 1C. The products are subjected to high

temperatures with the increasing temperature during

convective drying. Therefore, the product colour is

adversely affected by convective drying applications

realised at high temperatures.

ARTICLE IN PRESS

Table 2

Comparison between microwave, vacuum and convective drying methods for colour parameters during nettle leaves drying

(

L, brightness (+100)/ darkness (+0); a, redness (+50)/greenness (50) coordinate; b, yellowness (+50)/blueness (50)

coordinate;

C, chroma; a1, hue angle)

Drying method

Colour parameters

L

a

b

C

a1

Fresh

2764

a

(

70330)

686

a

(

70176)

967

a

(

70146)

1185

a

(

70216)

12535

ab

(

7037)

Microwave drying

850 W

2693

ab

(

70209)

665

a

(

70116)

919

ab

(

70180)

1134

ab

(

70210)

12588

a

(

7023)

750 W

2650

bcd

(

70227)

641

ab

(

70169)

898

bc

(

70068)

1103

bc

(

70153)

12553

a

(

7051)

650 W

2612

bcde

(

70087)

613

bc

(

70069)

874

bcd

(

70099)

1068

bcd

(

70120)

12507

ab

(

7006)

500 W

2571

de

(

70207)

586

cd

(

70144)

833

de

(

70197)

1019

de

(

70244)

12514

ab

(

7003)

Vacuum drying

75 1C–20 mm [Hg]

2659

bc

(

70217)

646

ab

(

70154)

899

bc

(

70076)

1107

bc

(

70152)

12570

a

(

7042)

75 1C–50 mm [Hg]

2606

cde

(

70030)

610

bc

(

70029)

866

cd

(

70032)

1059

cd

(

70043)

12515

ab

(

7003)

50 1C–20 mm [Hg]

2569

de

(

70155)

584

cd

(

70092)

832

de

(

70142)

1017

de

(

70170)

12506

ab

(

7003)

50 1C–50 mm [Hg]

2485

fg

(

70147)

546

de

(

70115)

783

ef

(

70104)

954

ef

(

70151)

12489

ab

(

7022)

Convective drying

50 1C

2544

ef

(

70121)

566

cd

(

70093)

808

e

(

70127)

986

e

(

70158)

12504

ab

(

7004)

75 1C

2418

g

(

70072)

502

e

(

70047)

745

f

(

70049)

899

f

(

70067)

12398

b

(

7008)

100 1C

2219

h

(

70199)

323

f

(

70177)

610

g

(

70139)

691

g

(

70205)

11788

c

(

7077)

125 1C

1963

i

(

70383)

200

g

(

70139)

508

h

(

70194)

556

h

(

70230)

11139

d

(

7067)

Probability Po001 Column mean values with different superscripts are significantly different.

I. ALIBAS

500

In vacuum drying, the greatest loss in brightness was

determined at 50 1C temperature and 50 mm [Hg]

vacuum combinations. Values nearest to the colour

values (L, a, and b) of fresh nettle leaves were obtained

with the combinations of 75 1C–20 mm [Hg] and

75 1C–50 mm [Hg].

In all drying methods, colour values closest to those

of fresh nettle leaves were obtained in microwave drying.

The brightness L value most approximate to those of

fresh nettle leaves was determined in 850 W microwave

power levels, while the most distant brightness L value

was found at 125 1C temperature.

4. Conclusion

The effects of three different drying methods on the

drying of nettle leaves were evaluated based on the

drying parameters such as the drying time, the moisture

content on dry basis, the drying rate, energy consump-

tion and colour criteria. The microwave drying period

was completed between 45 and 6 min at the microwave

powers between 750 and 500 W, while the energy

consumption was constant (007 kW h). The energy

consumption at 850 W microwave levels with the short-

est drying period (4 min) was determined as 006 kW h.

The most suitable methods after microwave drying

method with respect to energy consumption are

convective-drying and vacuum-drying methods, in

decreasing suitability order. Drying period lasted for

30–120 min in convective-drying method, depending on

temperature level (125–50 1C). The drying period in

vacuum drying method ranged from 35 to 65 min,

depending

on

vacuum-temperature

combination

(50 1C–50 mm [Hg] and 75 1C–20 mm [Hg]). Results

closest to those of fresh products with respect to colour

criteria were obtained from microwave drying method,

and this was followed by vacuum and convective drying

methods, in order. The best values of colour criteria,

drying time, energy consumption and drying rate were

obtained at 850 W microwave power levels.

References

Adu B; Otten L (1996). Diffusion characteristics of white beans

during microwave drying. Journal of Agricultural Engineer-

ing Research, 64(1), 61–69

Akgul A (1993) Spices Science and Technology. Association

Food Technology, Publ. No. 15. Ankara, Turkey

Alibas I (2006). Characteristics of chard leaves during

microwave, convective, and combined microwave-convec-

tive drying. Drying Technology, 24, 1425–1435

Alibas-Ozkan I; Akbudak B; Akbudak N (2005). Microwave

drying characteristics of spinach. Journal of Food Engineer-

ing, 78(2), 577–583

Allardice P (1993). A–Z of Companion Planting. Cassell

Publishers Ltd, London

Bouraout M; Richard R; Durance T (1994). Microwave and

convective drying of potato slides. Journal of Food Process

Engineering, 17, 353–363

Chevallier A (1996). The Encyclopedia of Medicinal Plants.

Dorling Kindersley, London

Chua J K; Chou K S (2005). A comparative study between

intermittent microwave and infrared drying of bioproducts.

International Journal of Food Science and Technology, 40,

23–39

Demir V; Gunhan T; Yagcioglu A K; Degirmencioglu A (2004).

Mathematical modelling and the determination of some

quality parameters of air-dried bay leaves. Biosystems

Engineering, 88, 325–335

Dı´az G R; Martı´nez-Monzo´ J; Fito P; Chiralt A (2003).

Modelling of dehydration-rehydration of orange slices in

combined microwave/air drying. Innovative Food Science &

Emerging Technologies, 4, 203–209

Doymaz I; Pala M (2002). Hot-air drying characteristics of red

pepper. Journal of Food Engineering, 55, 331–335

Drouzas A E; Schubert H (1996). Microwave application in

vacuum drying of fruits. Journal of Food Engineering, 28,

203–209

Drouzas A E; Tsami E; Saravacos G D (1999). Microwave/

vacuum drying of model fruit gels. Journal of Food

Engineering, 39, 117–122

Facciola S; Cornucopia A (1990). Source Book of Edible

Plants. Kampong Publications, Vista

Feng H (2002). Analysis of microwave assisted fluidized-bed

drying of particulate product with a simplified heat and

mass transfer model. International Communications in Heat

and Mass Transfer, 29, 1021–1028

Feng H; Tang J (1998). Microwave finish drying of diced apple

slices in a spouted bed. Journal of Food Science, 63,

679–683

Funebo T; Ohlsson T (1998). Microwave-assisted air dehydra-

tion of apple and mushroom. Journal of Food Engineering,

38, 353–367

Gulcin I; Kufrevioglu O I; Oktay M; Buyukokuroglu M E

(2004). Antioxidant, antimicrobial, antiulcer and analgesic

activities of nettle (Urtica dioica L). Journal of Ethnophar-

macology,, 90(2–3), 205–215

Kadlec P; Rubecova A; Hinkova A; Kaasova J; Bubnik Z; Pour

V (2001). Processing of yellow pea by germination,

microwave treatment and drying. Innovative Food Science

and Emerging Technologies, 2, 133–137

Lin T M; Durance T D; Seaman C H (1998). Characterization

of vacuum microwave air and freeze dried carrot slices.

Food Research International, 4, 111–117

Litvin S; Mannheim C H; Miltz J (1998). Dehydration of

carrots by a combination of freeze drying, microwave

heating and air or vacuum drying. Journal of Food

Engineering, 36, 103–111

Martı´nez-Para M C; Fidanza F; Torija-Isasa M E (1980a). La

ortiga en la alimentacio´n [English tradition IV] Fibra

alimentaria. Anales de Bromatologı´a, 32, 109–118

Martı´nez-Para M C; Fidanza F; Torija-Isasa M E (1980b). La

ortiga en la alimentacio´n [English tradition V] Estudio de la

proteı´na. Anales de Bromatologı´a, 32, 309–314

Martı´nez-Para M C; Torija-Isasa M E (1980). La ortiga en la

alimentacio´n [English tradition III] Ascorbic acid. Anales de

Bromatologı´a, 32, 295–298

ARTICLE IN PRESS

ENERGY CONSUMPTION AND COLOUR CHARACTERISTICS OF NETTLE LEAVES

501

Maskan M (2000). Microwave/air and microwave finish drying

of banana. Journal of Food Engineering, 44, 71–78

Maskan M (2001). Drying, shrinkage and rehydration

characteristics of kiwifruits during hot air and microwave

drying. Journal of Food Engineering, 48, 177–182

Menges O H; Ertekin C (2005). Mathematical modelling of

thin layer drying of Golden apples. Journal of Food

Engineering, 77(1), 119–125

Methakhup S; Chiewchan N; Devahastin S (2005). Effects of

drying methods and conditions on drying kinetics and

quality of Indian gooseberry flake. LWT—Food Science

and Technology, 38(6), 579–587

Montgomery S W; Goldschmidt V W; Franchek M A (1997).

Vacuum assisted drying of hydrophilic plates: static drying

experiments. International Journal of Heat Mass Transfer,

41, 735–744

Mwithiga G; Olwal J O (2005). The drying kinetics of kale

(Brassica oleracea) in a convective hot air dryer. Journal of

Food Engineering, 71, 373–378

Pere C; Rodier E (2002). Microwave vacuum drying of porous

media: experimental study and qualitative considerations of

internal transfers. Chemical Engineering and Processing, 41,

427–436

Prabhanjan D G; Ramaswamy H S; Raghavan G S V (1995).

Microwave assisted convective air drying of thin layer

carrots. Journal of Food Engineering, 25, 283–293

Schiffmann R F (1995) Microwave and dielectric drying. In:

Handbook of Industrial Drying (Mujumdar A S (ed), pp

345–372. New York, USA

Soysal Y (2004). Microwave drying characteristics of parsley.

Biosystems Engineering, 89, 167–173

Sumnu G; Turabi E; Oztop M (2005). Drying of carrots in

microwave and halogen lamp–microwave combination

ovens. LWT—Food Science and Technology, 38, 549–553

Torringa E; Esveld E; Scheewe I; van den Berg R; Bartels P

(2001). Osmotic dehydration as a pre-treatment before

combined microwave-hot-air drying of mushrooms. Journal

of Food Engineering, 49, 185–191

Tsami E; Krokida M K; Drouzas A E (1998). Effect of drying

method on the sorption characteristics of model fruit

powders. Journal of Food Engineering, 38, 381–392

Tulasidas T N; Ratti C; Raghavan G S V (1997). Modelling of

microwave drying of grapes. Canadian Agricultural En-

gineering, 39(1), 57–67

Walde S G; Balaswamy K; Velu V; Rao D G (2002). Microwave

drying and grinding characteristics of wheat (Triticum

aestivum). Journal of Food Engineering, 55, 271–276

Weiss R F (1988). Herbal Medicine. Beaconseld Publishers,

London

Yongsawatdigul J; Gunasekaran S (1996). Microwave-vacuum

drying of cranberries: part II, quality evaluation. Journal of

Food Processing and Preservation, 20, 145–156

ARTICLE IN PRESS

I. ALIBAS

502

Document Outline

Wyszukiwarka

Podobne podstrony:

Improving nutritional value of dried blueberries combining microwave vacuum, hot air drying and free

The energy consumption and economic costs of different vehicles used in transporting woodchips Włoch

Effective Moisture Diffusivity of Plain Yogurt Undergoing Microwave Vacuum Drying

Experimental study on drying of chilli in a combined Microwave vacuum rotary drum dryer (Weerachai K

Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opi

Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying

Improved Characterization of Nitromethane, Nitromethane Mixtures, and Shaped Charge Jet

Production and Characterisation of extracts

EFFECTS OF EATING AND NOT EATING ON ENERGY STORES AND BODY WEIGHT

Detection and Molecular Characterization of 9000 Year Old Mycobacterium tuberculosis from a Neolithi

38704314 SM01 Intro Conservation of Information Energy Entropy And Temperature

#1038 Types and Characteristics of Apartments

Mirlin Statistics of energy levels and eigenfunctions in disordered systems (PR326, p259, 2000)(124s

Corrosion behavior and surface characterization of titanium

2001 In vitro fermentation characteristics of native and processed cereal grains and potato

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

Bell locality and the nonlocal character of nature

Drying kinetics and rehydration characteristics of microwave vacuum and convective hot air dried mus

DIN 61400 21 (2002) [Wind turbine generator systems] [Part 21 Measurement and assessment of power qu

więcej podobnych podstron