27

Drying of Potato, Sweet Potato,

and Other Roots

Shyam S. Sablani and Arun S. Mujumdar

CONTENTS

27.1 INTRODUCTION

For many centuries potato, Solanum tubersum, has

served as the primary food source for people in

many parts of the world. The potato, with a total

production in excess of 300 million tons, is one of

the major food crops grown in a wide variety of soils

and climatic conditions. Many cultivars of potatoes

are grown, however, a few cultivars account for most

of the potatoes produced. These differ in time of

maturity, yield, appearance, disease resistance, mar-

keting, and processing quality. The majority of pota-

toes are used as table food these days, frequently

consumed in different forms of processed potato

ß

2006 by Taylor & Francis Group, LLC.

produc ts. In developed cou ntries, mo re than 50%

of potatoe s produced are consumed as process ed

produc ts. The process ed produ cts may be in the

form of chips, granule s, fla kes, power , dice, strips,

powder , etc. [1].

The chemi cal comp osition of potato de pends on

many fact ors includin g genetic features, age and ma-

turity, as well as en vironm ental co ndition s, i.e., cli-

matic an d soil conditio ns, weather and growing

conditi ons, such as fertil ization, pe sticides, diseas es,

etc. Tabl e 27.1 shows the chemi cal c omposi tion of

potato tuber. The potatoe s are a consider ably richer

source of nutri ent than energy. Starch is the basic

compon ent of pot ato dry matter, con tributing the

major amount of energy obt ained by potato con -

sumpt ion. Potato co ntains some nonstar ch polysac -

charide s, which con stitute dieta ry fibe r. Potato protein

is of superi or importance among all the nutri ents

because of its high biologi cal value. Potato also co n-

tains valuabl e miner als, such as iron and magnes ium,

and essential vitamins, such as vitamin C and several

of B vitamins [2]. The levels of calories, protein, min-

erals, and vitamins in raw and processed potato

produc ts are sho wn in

27.2 PREPROCESSING

27.2.1 P

EELING

Peeling is one of the most important steps in potato

processing. The yield of finished product depends on

effectiveness, efficiency, and method of peeling. In

recent years, waste disposal problems have become

acute in the processed industries including potato pro-

cessing. Because the peeling process generates more

waste than all of the other potato-processing operations

combined, it is important when designing and selecting

peeling systems to give proper considerations [3].

The potatoes must be thoroughly washed to re-

move all mud, dirt, and sand. Potatoes are often

washed in machines fitted with cylinder brushes or

studded rubber rolls that vigorously scrub the pota-

toes as they are tumbled and sprayed with water.

Washing also assists in sprout removal. Equipment

using large amounts of water for washing is now a

concern to processors because of the need to recycle

the water to meet required water pollution controls.

Generally, brush washers use much less water than

barrel washers or deepwater washers.

Potatoes are peeled by the use of heat, chemicals,

and mechanical abrasive methods. The most common

industrial processes are caustic (lye) peeling, steam

peeling, and abrasive peeling. The selection of method

depends upon the type and variety of products to be

produced and the anticipated capacity of the plant.

Abrasive peeling is commonly used in the potato chip

industry, where minimal peeling is required, and in

the canned potato industry, where abrasive action is

utilized to shape the potatoes. Abrasive peelers are

available either as batch-type units or continuous

machines. In steam peeling, potatoes are subjected

to steam pressure to rapidly heat and soften the peel

and underlying surface tissue. The steam pressure is

then suddenly released, causing vaporization of

moisture in the heated surface tissue, which further

loosens the peel. The peel is then removed either with

barrel-type washers or by dry scrubbers. Steam

peelers are available in both batch and continuous

types. Caustic or lye peeling of potatoes combines

the chemical and thermal effects for peeling. In this

process, washed potatoes come in contact with hot

dilute lye solution followed by washing with high-

pressure water sprays. Sometimes combination of lye

and steam peeling is also used for peeling of pota-

toes. The efficiency of lye peeling method can further

be improved using an infrared heating treatment

of potatoes after potatoes are immersed in more

dilute caustic solution. The potato surfaces are ex-

posed to infrared radiation at 9008C for 90 s. This

accelerates the chemical activity, thereby utilizing

TABLE 27.1

Chemical Composition of Potato Tubers

Component

Content (%)

Average

Range

Dry matter

23.7

13.1–36.8

Starch

17.5

8.0–29.4

Reducing sugars

0.3

0.0–5.0

Total sugars

0.5

0.05–8.0

Crude fiber

0.71

0.17–3.48

Pectic substances

—

0.2–1.5

Total nitrogen

0.32

0.11–0.74

Crude protein

2.00

0.69–4.63

Amide nitrogen

—

0.029–0.052

Amino acid nitrogen

—

0.065–0.098

Nitrates

—

0.0–0.05

Lipids

0.12

0.02–0.2

Ash

1.1

0.44–1.87

Organic acids

0.6

0.4–1.0

Ascorbic acid and dehydroascorbic

acid (mg/100 g)

10–25

1–54

Glycoalkaloids (mg/100 g)

3–10

0.2–41

Phenolic compounds

—

5–30

Source: From Leszczynski, W., in: Potato Science and Technology,

Lisinska, G. and Leszczynski, W., Eds., Elsevier Science Publishing

Co., Inc., New York, 1989, pp. 11–128.

ß

2006 by Taylor & Francis Group, LLC.

TABLE 27.2

Composition of Potatoes and Potato Products per 100 g Edible Portion

Product Type

Water

(%)

Food

Energy (cal)

Protein

(g)

Fat

(g)

Carbohydrate

(g)

Calcium

(mg)

Iron

(mg)

Thiamin

(mg)

Riboflavin

(mg)

Niacin

(mg)

Ascorbic

acid (mg)

Raw

79.8

76

2.1

0.1

17.1

7

0.6

0.10

0.04

1.5

20

Baked in skin

75.1

93

2.6

0.1

21.1

9

0.7

0.10

0.04

1.7

20

Boiled in skin

79.8

76

2.1

0.1

17.1

7

0.6

0.09

0.04

1.5

16

French-fried

44.7

274

4.3

13.2

36.0

15

1.3

0.13

0.08

3.1

21

Fried from raw

46.9

268

4.0

14.2

32.6

15

1.1

0.12

0.07

2.8

19

Hash-brown after holding night

54.2

229

3.1

11.7

29.1

12

0.9

0.08

0.05

2.1

9

Mashed, milk and fat added

79.8

94

2.1

4.3

12.3

24

0.4

0.08

0.05

1.0

9

Canned, solids and liquid

88.5

44

1.1

0.2

9.8

–

0.3

0.04

0.02

0.6

13

Dehydrated mashed, granules,

water, milk, fat

78.6

96

2.0

3.6

14.4

32

0.5

0.04

0.05

0.7

3

Frozen, cooked, hash-browned

56.1

224

2.0

11.5

29.0

18

1.2

0.07

0.02

1.0

8

Frozen, french-fried, heated

52.9

220

3.6

8.4

33.7

9

1.8

0.14

0.02

2.6

21

Frozen, mashed, heated

78.3

93

1.8

2.8

15.7

25

0.6

0.06

0.04

0.7

4

Potato chips

1.8

568

5.3

39.8

50.0

40

1.8

0.21

0.07

4.8

16

Potato flour

7.6

351

8.0

0.8

79.9

33

17.2

0.42

0.14

3.4

19

Source: From McCay, C.M., McCay, J.B., and Smith, O., in: Potato Processing, 4th ed., Talburt, W.F. and Smith, O., Eds., An AVI Book by Van Nostrand Reinhold Company, Inc., New York,

1987, pp. 287–332.

ß

2006

by

Taylor

&

Francis

Group,

LLC.

the caustic more completely and reducing caustic

consumption [3].

27.2.2 B

LANCHING

Peeled potatoes are cut in the form of slices, dices,

and strips before blanching. After potatoes are cut in

desirable form, they are blanched by heating, either in

steam or hot water (93 to 1008C). Blanching destroys

or inactivates enzymes; otherwise, potatoes may

darken during dehydration and develop off-flavors

and off-odors during storage. Blanching also serves

to reduce microbial contaminations and affects the

way the dehydrated product reconstitutes. Degree of

blanching has a very marked effect on the texture and

appearance of finished product as well as on the way

the potato tissue dehydrates and reconstitutes. The

potatoes are sulfided immediately after blanching

using sodium sulfite, sodium bisulfite, sodium meta-

bisulfite, or combinations. Sulfite protects the product

from nonenzymatic browning or scorching during de-

hydration and increases the storage life of the product

under adverse temperature conditions.

27.3 DATA ON USEFUL PROPERTIES

Data on physical, thermal, and thermodynamic pro-

perties of potato, sweet potato, and other roots are

presented in Table 27.3 through

. Such pro-

perty data are required in product development, process

design, and quality control. The data are presented in

tabular form. Various prediction models are also

compiled for different processing conditions.

27.4 DRYING METHODS AND

CONDITIONS

Dehydration of potato dates back to as early as 200

AD

when it was cultivated in the mountainous areas of

Peru [1]. Today the drying process is considered one

of the most important unit operations in the produc-

tion of a variety of commercial potato products in-

cluding granules, flakes, diced dehydrated potatoes,

and potato starch and flour. The drying process in

potato processing can be the end-stage operation (for

dehydrated slices, dices, strips, flakes, starch, flour,

etc.), accompany-end-stage operation (for granulates,

instant products), or mid-stage operation (for chips

and fresh fries as predrying before frying in modern

technologies). Various drying methods are employed

to achieve desired product. In this section, different

drying methods and operating conditions used in the

processing of potatoes are described. Details on the

drying equipment can be found in other chapters of

this handbook.

TABLE 27.3

Moisture Diffusivity and Activation Energy for Moisture Diffusivity

Drying

Methods

Moisture Content

(Dry Basis kg/kg)

Temperature

(8C)

Moisture

Diffusivity 3 10

10

(m

2

/s)

Activation

Energy (kJ/mol)

Ref.

Potato

Air-drying

0.15

65

2.0

40

Air-drying

—

65

14

41

Air-drying

—

60–80

2.4–2.6

42

Air-drying

—

65

9.0

16.3

43

Air-drying

0.03–5.0

60–100

2.8–53

17.0

44

Air-drying

—

31

0.6–1.6

45

Air-drying

0.05–1.50

30–70

0.2–4.2

30–108

46

Air-drying

—

30–90

1.1–4.5

47

Air-drying

—

40

8.8–12

48

Air-drying

0.10–1.00

65

4.4

52.2

49

Air-drying

—

60

1.8

50

Infrared drying

3.39–4.96

23.5–55

0.6–17.3

18

Air-drying

—

30

0.03–0.2

51

Freeze-drying

—

30

1.3–3.2

51

Freeze-drying

0.01–0.10

30

0.083

52

Puff drying

—

30

0.20–0.70

51

Sweet potato

Air-drying

0.10–3.5

328

3.7–4.35

53

ß

2006 by Taylor & Francis Group, LLC.

27.4.1 C

ONVENTIONAL

D

RYING

Cabinet, tunnel, rotary, drum, or conveyor dryers

have normally been used at the industrial scale to

produce various potato products. The following

description of potato drying is based on the type of

dried product.

27.4.1.1 Diced Potatoes

Practically all diced potatoes are produced on con-

veyor (or apron) dryers, although a few tray and

tunnel dryers still are in use. Due to ease of automa-

tion in conveyor dryers, the material handling costs

are reduced significantly. The conveyor dryer is

designed appropriately in stages so that the condi-

tions of the air (i.e., temperature, humidity, quantity,

and speed) can be adjusted in a desirable manner as to

result in the highest quality of dried product. The most

TABLE 27.4

Relationships Showing Moisture Diffusivity as a

Function of Temperature and Moisture Content

for Potato

Parametric Model

Ref.

D(m,T)

¼ a

0

exp

ð

a

1

m

exp

a

2

T

44

a

0

¼ 1.29 10

6

, a

1

¼ 7.25 10

2

,

a

2

¼ 2044

0.03 < m < 5.0, 333 < T < 373

D(m,T)

¼ a

0

(m) exp

ð

a

1

exp (

a

2

m)

þ a

3

T

46

a

1

¼ 168, a

2

¼ 15.4, a

3

¼ 30

D(m, T, L)

¼ a

0

þ a

1

m

þ a

2

T

þ a

3

L

18

a

0

¼ 7.015 10

11

, a

1

¼ 2.11 10

10

,

a

2

¼ 2.57 10

11

, a

3

¼ 7.96 10

11

0.3 < m < 3.39, 296 < T < 328, 2.2 < L < 11.0 (L in mm)

TABLE 27.5

BET and GAB Monolayer Values

Product

T (8C)

M

K

Y

A/D

Ref.

Potato

19.5

0.075

D

54

20.0

0.074

A

25.0

0.052

A

30.0

0.057

A

40.0

0.061

A

60.0

0.048

A

80.0

0.037

A

Potato

0.051–0.078

55

Potato starch

0.066

Potato dice

0.060

56

Potato (freeze-dried)

20

0.066

0.849

19.10

A

57

Potato sliced

25

0.083

0.774

8.50

A

Potato vacuum dried

25

0.130

0.700

1.39

A

Potato vacuum dried

25

0.091

0.725

8.62

D

Potato

40

0.052

0.830

13.73

A

58

50

0.048

0.820

13.41

A

60

0.036

0.860

21.18

A

70

0.029

0.900

17.75

A

40

0.059

0.840

12.52

D

50

0.061

0.820

8.89

D

60

0.053

0.840

8.57

D

70

0.057

0.800

4.37

D

Potato (Pentland Dell)

30

0.061

999.7

0.86

A

59

45

0.068

10.2

0.77

A

60

0.031

990.1

0.88

A

30

0.089

14.45

0.78

D

45

0.074

15.68

0.81

D

60

0.046

19.99

0.84

D

Mushroom

25

0.058

A

54

ß

2006 by Taylor & Francis Group, LLC.

common dryer for diced potato is the two-stage dryer.

The first stage of the dryer is divided into two sec-

tions. Potato dice bed height and the size of diced

potato srongly influence the drying rates. The bed

height is maintained constant along the conveyor for

proper distribution of drying air and good product

quality. Typical bed height is in the range of 7.5 to 15

cm. The temperature of the drying air in the first

section of the first stage is in the range 93–1278C, in

the second section of first stage 71–1058C, and in the

second stage 55–828C. The moisture content of 6–7%

(wb) for dried potato is sufficient for proper storage.

A further extension of the storage time will require

reduction of moisture content to 3–4% (wb), which

can be achieved by long-time sorption drying using

sorption agents such as calcium oxide.

A belt-trough dryer has been used to produce

very high-quality diced potato [4,5]. Only vacuum

drying or freeze-drying can produce a more porous

product than products dried using a belt-trough

dryer. The dryer consists of an endless, closely

TABLE 27.6

Sorption Data (Average) of Different Peanut

Varieties at 258C

a

w

Moisture Content (% db)

Flour

Rummer

Tobaldo

Colorado

Roata

0.577

5.6

6.0

5.8

5.5

0.751

8.8

9.0

8.8

8.8

0.803

10.6

10.6

10.7

10.0

0.842

12.9

13.0

12.8

12.6

0.903

17.6

18.2

18.0

17.4

Source: From Bianco, A.M., Boente, G., Pollio, M.L., and Resnik,

S.L., J. Food Eng., 47, 327, 2001.

TABLE 27.7

Net Heat of Sorption

Product

M

w

T Range (8C)

A/D

Q (kJ/kg)

Ref.

Potato

0.05

10–80

A

562.3

61

0.10

10–80

A

310.5

0.15

10–80

A

166.8

0.060

10–80

D

1933.3

Potato

0.080

30–60

D

1555.6

62

0.100

30–60

D

1283.3

0.120

30–60

D

883.3

0.140

30–60

D

644.4

0.160

30–60

D

527.8

0.180

30–60

D

461.1

TABLE 27.8

Data and Prediction Model for Thermal Conductivity

Product

X

w

(% wb)

Apparent Density

(kg/m

3

)

T (8C)

Thermal

Conductivity

(W/mK)

Ref.

Potato variety

Katahdin

81.4

1040

25.5

0.533

63

Russet burbank

82.9

1040

24.8

0.571

Kennebec

82.4

1050

25.0

0.549

Monona

83.6

1040

24.6

0.547

Norchip

81.2

1050

25.9

0.533

Potato

83.5

—

25.0

0.563

64

83.5

—

75.0

0.622

83.5

—

105.0

0.639

83.5

—

130.0

0.641

k

¼ 0.1445 þ 0.389X

w

W/mK; T

¼ 30; 0 < X

w

<

1.0

65

Potato variety: Bintje

k

¼ 0.624 þ 1.19 10

3

T W/mK; 293 < T < 358; X

w

¼ 79.8%

66

Potato variety: Bintje

Sweet potato

Beauregard

—

995

25

0.481

67

Hernandez

—

996

25

0.536

Jewel

—

1003

25

0.597

ß

2006 by Taylor & Francis Group, LLC.

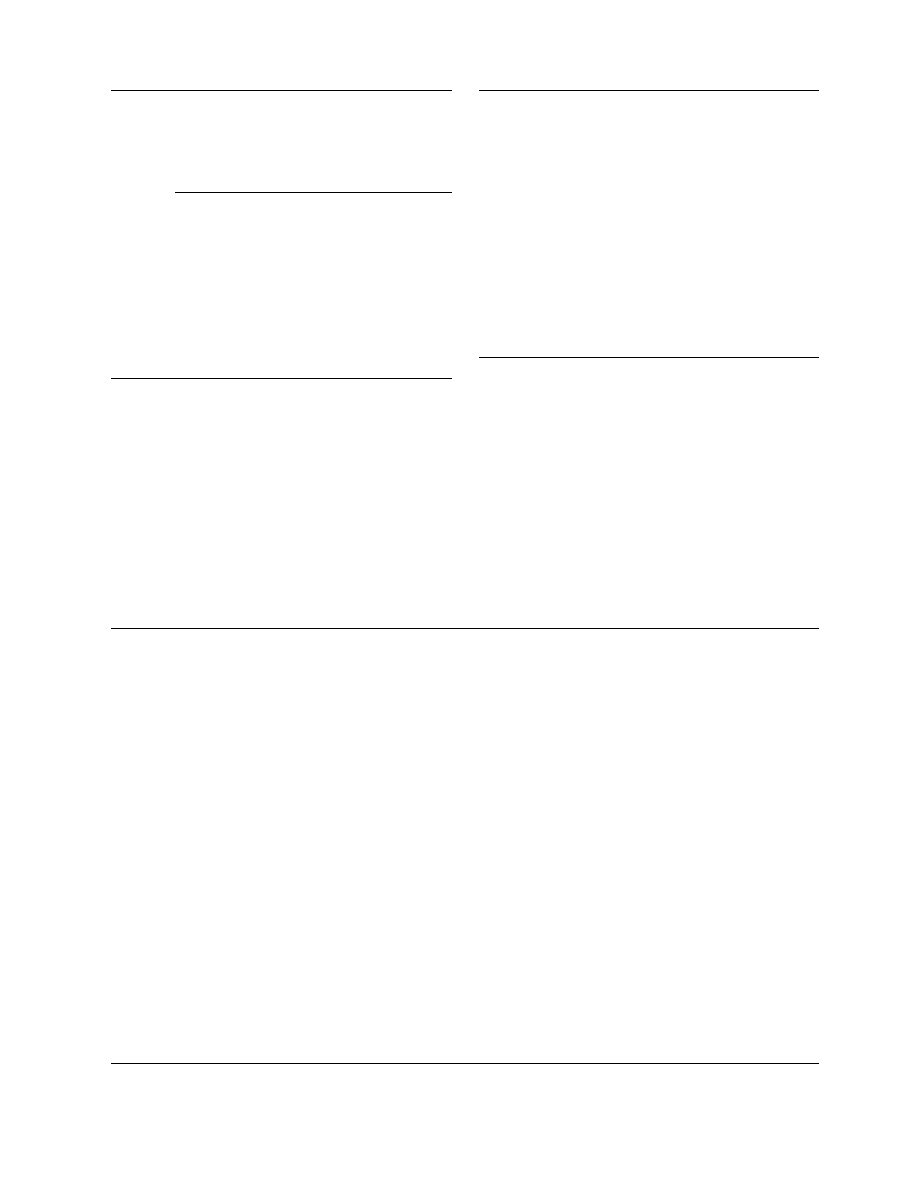

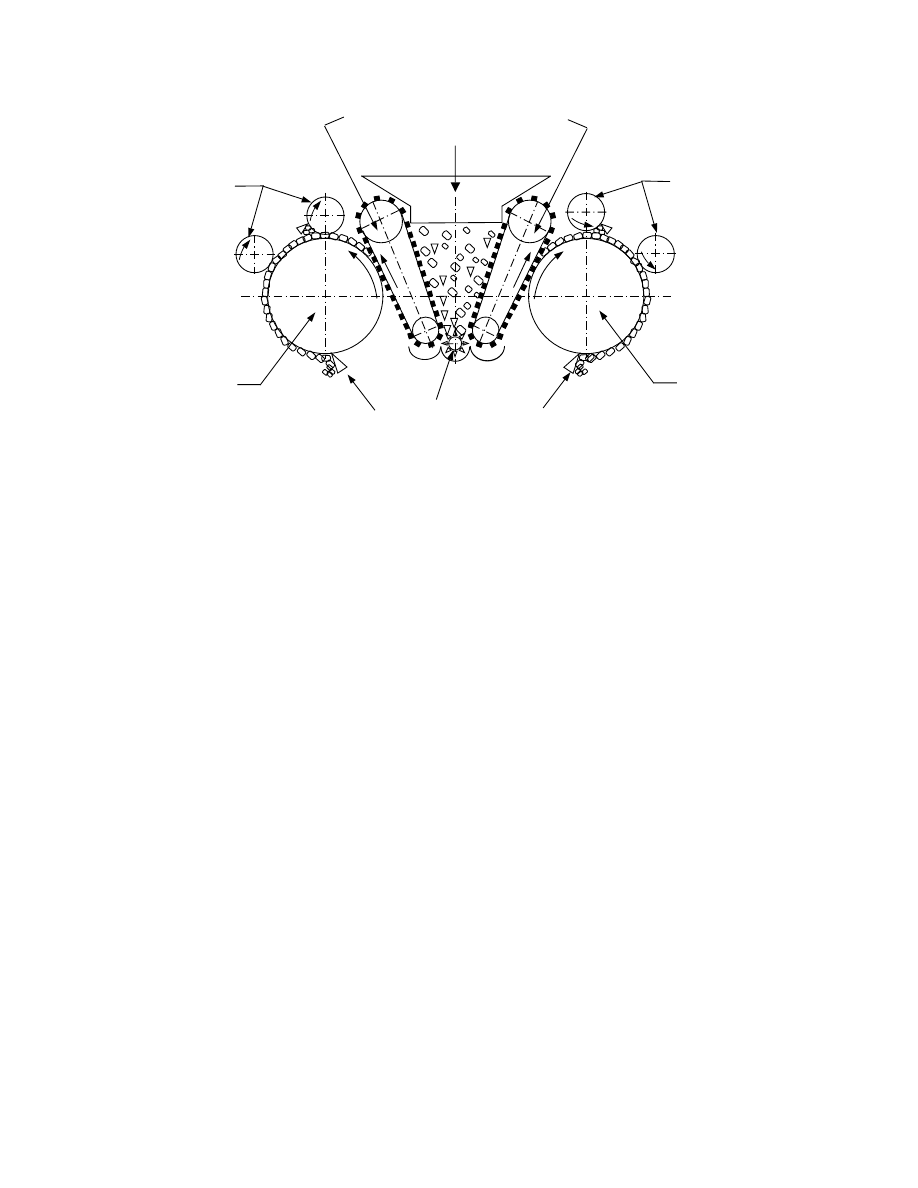

woven meta l-mesh conveyo r belt supp orted between

two hor izontal roll s with a great deal of slack so that

it han gs freely (

). The potato pieces are

turned and agit ated as they trave l wher eas hot a ir is

blown up throu gh the bed . The airflow pr ovides an

air cushion to potato pieces but doe s bot fluidized

them. The standar d be lt-troug h dr yer, which has a

bed 1.2 m wid e and 3 m long, evaporat es 450 kg of

moisture per hour [4]. In this dryer, the moisture level

achieve d in individ ual diced potato is nea rly the same.

The belt-tr ough dryer has proven to be capable of

making dehyd rated potato of better qua lity than

those produced by con vention al air-d ryers.

27.4.1 .2 Pot ato Strip s

Potato strip s are usuall y dried in con current rotary

dryers of 1 to 3 m diame ter an d 5 to 15 m lengt h.

The inlet and outlet air tempe ratures are ab out 500

and 100 8 C, respect ively. The fresh potato strips are

prepared by the slicer simila r to one used in the sug ar

indust ry. The potato strips are dried to a final mois -

ture content of 1 2% (w b). A signifi cant portion of the

dried potato strip is util ized as livestock feed since it is

the most economic al method of pr eserving pot ato.

The detai ls of rotary dryer can be found in Kell y [6].

27.4.1 .3 Pot ato Flake s

Potato fla kes are de hydrate d using drum dryers . Be-

fore drying, the potatoe s go through was hing, peel-

ing, sli cing, precoo king, co oling, and mashi ng [7].

Mashed potatoe s are then mixe d wi th severa l addi-

tives (emulsifier, chelating agent, milk solids, anti-

oxidants, and sulfur dioxide) to improve the texture

and extend the shelf life of the products; they also

influence the drying process.

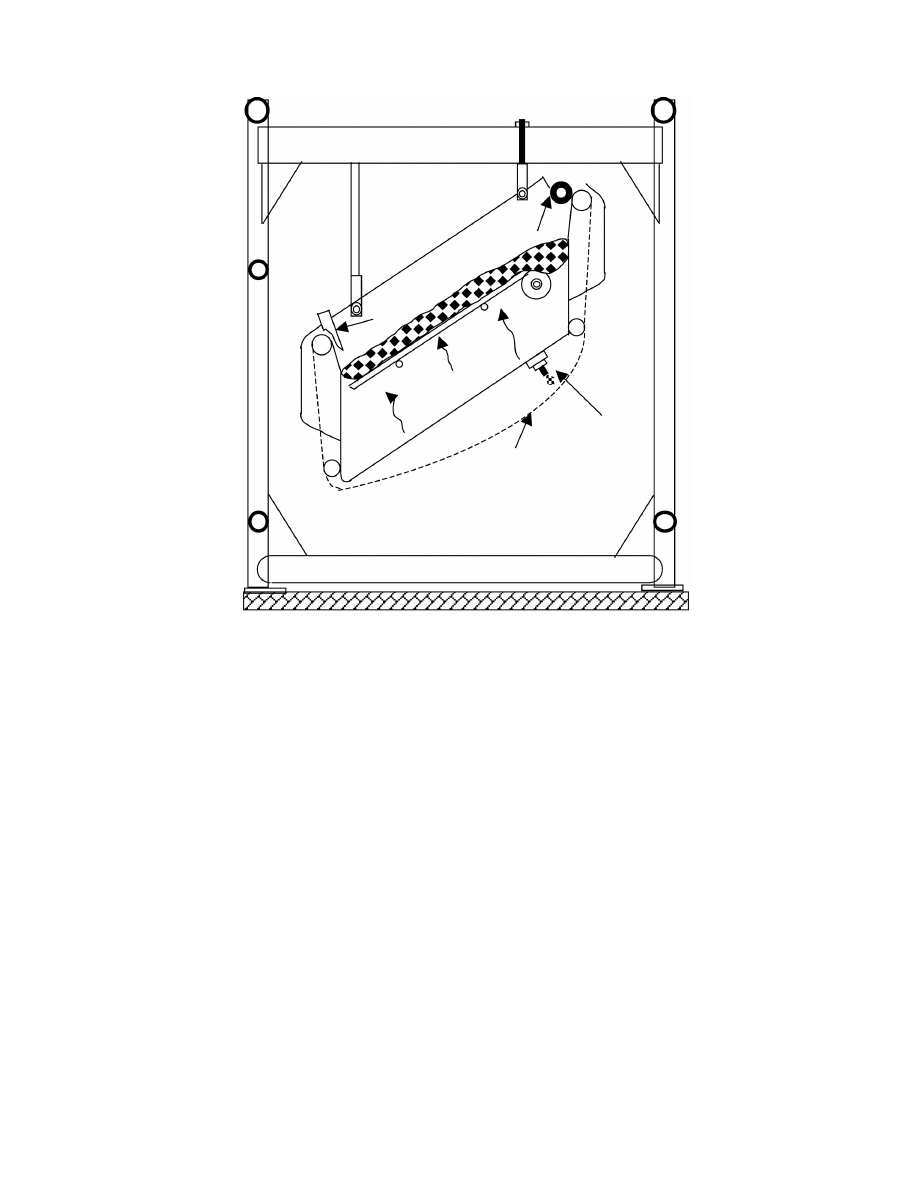

Generally, single-drum and double-drum dryers

are used to produce pot ato fla kes (

). The

most frequently used cylinders are 0.6–1.25 m in diam-

eter and 0.9–2.2 m in length (double drums), or 2.2–3.2

m in length (single drum). All drum dryers are

equipped with several (up to 6) applicator rolls. The

space between the applicator rolls allows steam to

escape and accumulate mash in the trough between

the roll and the dryer drum surface. The temperature

of the cylinders reaches 1408C. Saturated steam is used

as a heating medium. Mineral oil or gas is used as a

heating medium to achieve higher temperatures in the

range of 2508C. Such a high temperature allows higher

drum speeds, which are typically in the range 2 to 8

rpm. The dry product output is directly proportional

to drum speed but inversely proportional to potato

sheet density. The moisture content of dry potato

flake is in the range 6–7% (wb). Infrared radiation or

impinging jets may be used to enhance drying rates.

TABLE 27.9

Freezing Point

Product

X

w

T

f

(8C)

Ref.

Potato (white)

0.778

1.70

68

Sweet potato

0.685

1.90

68

T

¼ 14.46 þ 49.19X

w

37.07X

w

2

69

TABLE 27.10

Specific Heat

Product

X

w

Specific

Heat (kJ/kg K)

Ref.

Potato (raw)

0.75

3.515

70

Potato (boiled)

0.80

3.640

Potato (dried)

0.061 (27–608C)

1.715

71

Potato(dried)

0.080

1.925

Mushroom (fresh)

0.90

3.933

70

Mushroom (dried)

0.30

2.343

Cp

¼ 4.180 0.406 þ 1.46 10

3

T

þ 0.203M

w

2.49 10

2

M

w

2

72

0 < M

w

<

4.13 and 40 < T < 70; Desiree variety of potato

Sweet potato

Beauregard

995

a

3.726

67

Hernandez

996

a

3.677

Jewel

1003

a

3.499

Sweet potato (dried)

0.076

2.050

71

a

Apparent density (kg/m

3

).

TABLE 27.11

Thermal Diffusivity

Product

T (8C)

Thermal

Diffusivity

10

7

(m

2

/s)

Ref.

Potato (whole)

6 to 26

1.77

73

Potato (flesh)

20

1.48

74

Potato (Excel)

24 to 91

1.17

75

Potato (Irish)

18 to 27

1.23

Potato (Pungo)

—

1.31

Potato (several)

25

1.70

Sweet potato

Beauregard

25

1.30

67

Hernandez

25

1.46

Jewel

25

1.65

ß

2006 by Taylor & Francis Group, LLC.

Drum dryers are economical in operation, usually

requiring a maximum of 1.3 and a minimum of 1.1 kg

of steam per kilogram of evaporated water (76 to 90%

efficiency). Technical data on drum dryers applicable

in potato flake manufacturing have been presented by

Moore [8]. Many improvements have been made by

the manufacturers of potato flake dryers over the years.

For example, internal pressure has been increased from

100 to 125 psig to achieve increased production rate.

Internal design of the drying cylinder has been im-

proved to extend uniform heat transfer to the edge of

the dryer. Hydraulic dampers have been installed to

reduce wear and improve smoothness of operation.

Rod and handwheel devices to control end-board

tension have been replaced with air cylinders [7].

27.4.1.4 Potato Starch

The manufacture of potato starch is a simple and easy

process based on thorough comminution of potato

tubers, separation of starch from potato pulp, its

purification and dehydration. All the processing

steps before drying have been described in detail by

Lisinska and Leszczynski [9] and Treadway [10].

Starch milk obtained in the last stage of refining in

hydrocyclones or centrifuges dewatered by continu-

ous rotary vacuum filters. Extraction of water under

vacuum results in 36–38% water content of the starch.

After dewatering, starch is transported to the drying

section in which moisture level is reduced to 18–20%

by supplying hot dry air. The finished product con-

sists of 98–98.5% starch on dry basis. Since moist

starch granules begin to swell (gelatinize) at 458C,

the temperatures of moist starch are maintained

below 358C during drying. The final drying of moist

starch is carried out in flash (pneumatic) dryers. Such

dryers consist of a system of vertical pipes (large in

diameter) whereby starch is dried and transported by

the air supplied. The air with a velocity of 10 to 20 m/s

and temperatures of 160–1658C is mixed with starch.

Mixing is more efficient due to the extension of the

pipe. Water from the wet starch rapidly evaporates in

contact with the hot air. Due to the high evaporation

heat of the water removed from the starch, starch

Water spray

Endless wire-

mesh belt

Hot-air duct

Feed chute

Rotary

brush

FIGURE 27.1 Schematic cross section of belt-trough dryer. (From Sokhansanj, S. and Jayas, D.S., in: Handbook of Industrial

Drying, Mujumdar, A.S., Ed., Marcel Dekker, New York, 1987.)

ß

2006 by Taylor & Francis Group, LLC.

granule s are not heated to tempe ratur es higher than

40 8 C. The e ntire process of starch drying takes 2 to 5 s.

One of the important parts in potato starch techno-

logy is utilization of secondary products such as

extracted potato pulp (pomace) and the soluble con-

stituents of the protein water (fruit water). Potato pulp,

after dewatered mechanically to a dry matter content of

about 25%, is dried in drum or flash dryer using com-

bustion gases at 500–6008C. The dry product of rela-

tive ly high-fee ding value c ontai ns a bout 13 % o f w ate r.

Also fruit w a ter afte r va rious proc ess es w ith c en trifuging

at the end ca n b e drie d by on e o f the above-m entioned

met hods o r by s on ic or TorusDisc d ry ing [1 1].

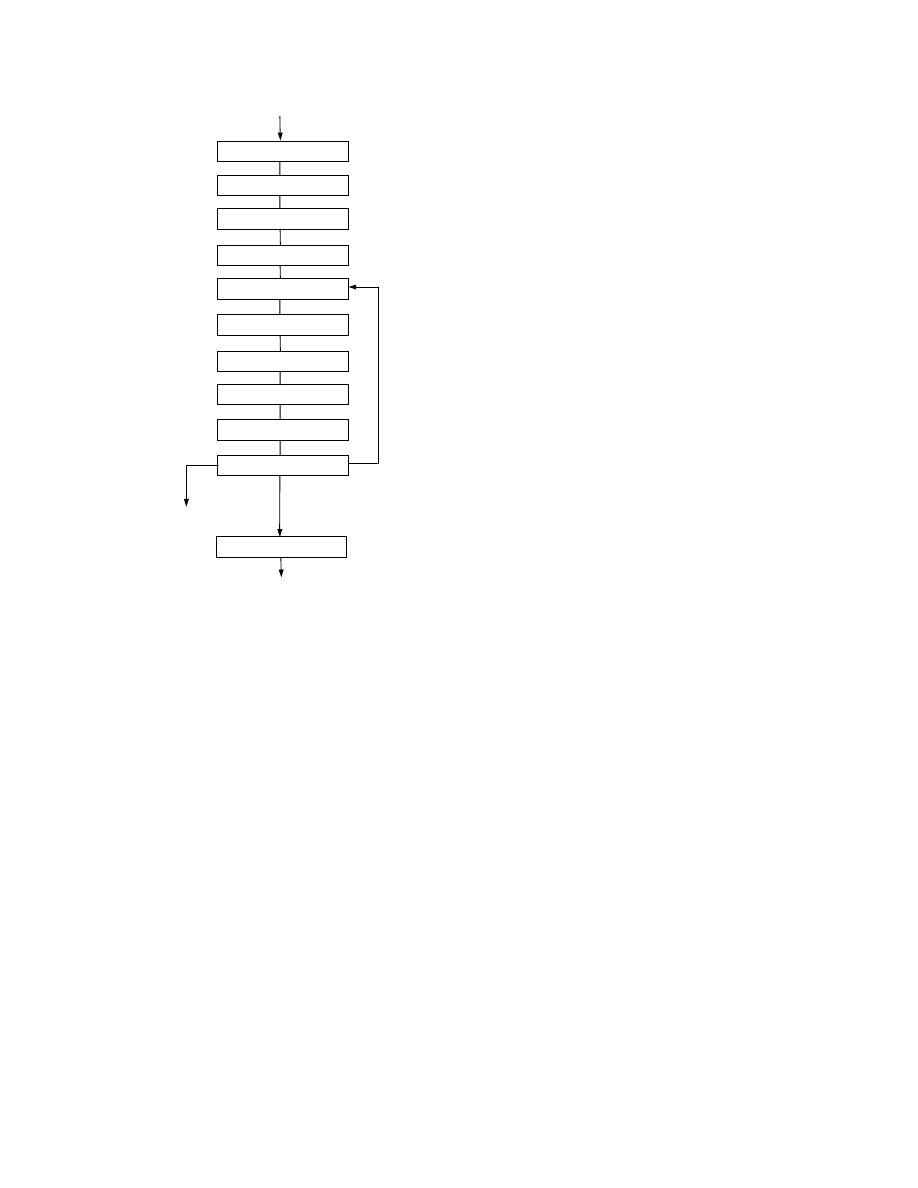

27.4.1 .5 Pot ato Gra nules

Potato granule s are de hydrate d and single cell s or

aggrega tes of cell s of pota to are dried to abo ut 6–

7% (w b) mois ture c ontent. The standar d commer cial

procedu re used for the produ ction of pot ato granule s

is know n as ‘‘add-back ’’ process (

). In this

process , coo ked potatoe s are partiall y dried by add ing

back enough previous ly dried granu les to give a mois t

mix, whi ch after holding can be satisfa ctorily gran u-

lated to a fine powder . In the manu facturing of pot ato

granule s, precaut ions are taken to (1) minimiz e ru p-

ture of the potato cells an d (2) produce satisfa ctory

granula tion. Hence all man ufacturing ope rations are

carried out as gently as possible.

Dryi ng of granula ted mois t mix is performed in

one or two stages to a bout 1 2–13% (wb ) mois ture

content . Airlift dryers are used in a singl e-stage op-

eration. The dryer co nsists of a verti cal tube with

upwar d flow of hot air. The moist feed en ters at the

bottom and drying occurs as the product is rising in

the tube. The airlift dryer ope rates at relative ly low

air velocitie s (7.5–10 m/s), with mini mum damage to

the potato cells. The two-stage dehyd ration of pota to

granule s is accompl ished in a pne umatic dryer (to

remove surfa ce moisture) follo wed by a fluidized

bed dryer–c ooler. The tempe ratures of inlet and out-

let air in the pne umatic dryer are 175 and 80 8 C,

respectivel y. The prod uct leaves pneu matic dryer at

moisture content of ab out 17–19 % (wb ). A two -

chamber fluidized bed (with drying in the first cham-

ber and cooling in the secon d chamber) is used in the

second stage to dry potato granule s up to 10–12%

(wb) mois ture content . The tempe ratur e of the pro d-

uct leavin g the secon d chamb er is obtaine d in the

range of 32–43 8 C.

The dried granule s of 10–12% (wb) mois ture co n-

tent are screened using meshes of diff erent sizes: 6 , 40,

and 105 mesh. The largest pa rticle fract ion from 6

mesh goes for stock feed and small particle fraction

passed from 105 mesh undergoes the final step of

rehydration. In between particle fraction is utilized

at add-back step and also for stock feed.

The drying of fine potato granules is carried out in

a fluidized bed dryer–cooler where the moisture con-

tent is reduced to 6–8% (wb). A multichamber fluid-

ized bed (or a vibrofluidized bed) or continuous-type

fluidized bed dryer is used in the final drying of potato

Drum

Drum

Shuttering potato mash spreader

Shredder

Impression

rollers

Impression

rollers

Doctor

knife

Doctor

knife

FIGURE 27.2 Scheme of Foerster double-drum potato flakes dryer. (From Lisinska, G. and Leszczynski, W., Potato Science

and Technology, Elsevier Science Publishing Co., Inc., New York, 1989, pp. 281–346.)

ß

2006 by Taylor & Francis Group, LLC.

granules. The residence time of potato granules in this

dryer is about 10 to 30 min.

27.4.1.6 Potato Chips and French Fries

In potato chips manufacturing, raw sliced potatoes

are partially dried before frying to reduce the frying

time and oil uptake. The raw sliced potatoes are dried

on a perforated, revolving drum, on a vibrating mesh

belt. The excess surface moisture of about 4% is

removed during drying.

In some chips manufacturing, drying process is

the finishing step or an alternative frying method.

For this, raw sliced potatoes may be partially fried

and then subjected to tunnel heat (at 1218C). to re-

move the excess moisture. The procedure results in

lighter colored chips. Finish drying time depends up

on the frying time; for drying in hot air at 1208C it is

about 1 min (frying time 1 min 40 s) or 4 min (frying

time 1 min 20 s).

In the production of frozen French fries, the sur-

face moisture of blanched potato strips is usually

removed before frying by blowing warm air over

them. This is done to reduce the load on the fryer

and to minimize the rate of hydrolytic breakdown of

the fat.

27.4.2 O

SMOTIC

D

EHYDRATION

Osmotic dehydration does not allow a product of low

moisture content to be considered shelf stable. Con-

sequently, an osmotically treated product is further

processed by air, vacuum, or freeze-drying methods.

Osmotic preconcentration followed by fluidized bed

drying of potato pieces to produce dehydrated quick-

cooking potato was studied by Ravindra and Chatto-

padhay [12]. They found that a solution of 50% sugar

and 10% salt at 478C for 4 h was optimum for osmotic

preconcentration. The moisture content of potato

cubes was reduced from 84 to 60% (wb). Drying at

1408C for 10 min at 5.3 m/s followed by thin-layer

drying at 50–608C and 0.75 m/s for about 7 h was

found to be optimal. Fluidized bed drying lowered the

moisture content to 30% (wb) and it was further

reduced to 5% (wb) during thin-layer drying.

27.4.3 V

ACUUM

, F

REEZE

,

AND

H

EAT

P

UMP

D

RYING

Vacuum drying involves subjecting food material to a

low pressure and a heating source. The vacuum al-

lows the water to vaporize at a lower temperature and

thus foods can be dried without exposure to high

temperature. Freeze-drying utilizes a high vacuum to

remove water from a solid phase (ice) to a vapor phase

without going through a liquid phase. Since the ma-

terial remains frozen and drying takes place at low

temperature, no heat damage occurs. Heat pumps are

known to be energy efficient when used in conjunction

with drying. Heat pump dryers can employ a wide

range of drying conditions (temperature

20 to

1008C and relative humidity 15 to 80%) to produce

better quality dried products [13]. Although product

quality obtained by vacuum or freeze-drying is super-

ior, both methods are expensive and they are not used

on industrial scale for potato products. Heat pump

drying is also not applied as widely as it should or

could be due to higher initial and operating costs.

27.4.4 M

ICROWAVE AND

I

NFRARED

D

RYING

The use of microwave energy has been of growing

interest in recent years. The interest is due to short

start-up times, volumetric heating, and reduced pro-

cessing times, making microwave an attractive source

of thermal energy. Although numerous studies on

Washing

Peeling and trimming

Slicing

Cooking

Mash-mixing

Cooling

Conditioning

Mixing

Drying

Screening

Final drying

Potato granules

Stock

feed

Coarse

Fine

powder

Intermediate size

Add-back granules

Raw potato tubers

FIGURE 27.3 Scheme of the add-back (solid back-mixing)

process for manufacture of potato granules. (From Talburt,

W.F., in: Potato Processing, 4th ed., Talburt, W.F. and

Smith, O., Eds., an AVI Book by Van Nostrand Reinhold

Company, Inc., New York, 1987, pp. 1–9.)

ß

2006 by Taylor & Francis Group, LLC.

microwave drying of potato have been reported in the

literature, microwave drying has not been employed

extensively on industrial scale. Microwave drying has

been evaluated for final stages of drying (between 30

and 6%) of different potato products. For example,

raw potato slices of 0.21 mm thick can be dried to

2–3% final moisture content within about 4 min in a

microwave field. Increasing the thickness of raw slices

to 0.32 mm leads to cooking effects and also a reduc-

tion in the drying rate [14]. Simultaneous air and

microwave drying of potato slices can overcome this

disadvantage but this type of potato-processing

equipment needs further industrial development to

make it cost-effective.

Microwave finish drying of potato chips has

found practical industrial application [14]. A 25-kW

oven can process about 320 kg/h of chips. The quality

of the product (color, texture, etc.) is reported to be

good whereas oil absorption was about 5% less com-

pared to conventionally processed chips. Similar

quality advantages have been reported in other stud-

ies [15,16]. This suggests that application of micro-

wave energy to finish drying process of potato chips

seems to have potential for use.

Far infrared (FIR) drying also has several advan-

tages over conventional drying [17]. Afzal and Abe

[18] studied FIR drying of potato slabs with radiation

intensity varying from 0.125 to 0.500 W/cm

2

. They

observed that drying rates increased with increasing

thickness of potato slab due to a lower activation

energy for moisture desorption. Later they demon-

strated that FIR drying of potato is a falling rate

process and drying rates were dependent on the radi-

ation intensity level [19].

27.5 QUALITY OF DRIED PRODUCTS

Potato is sensitive to heat and mechanical stress; thus

thermal degradation of potato products leads to losses

in quality (color, structure, shape, etc.) as well as nu-

trient content (nutrient value, vitamins, protein dam-

age, etc.). The quality of dried potatoes is not only

affected by drying methods and conditions but also

by preprocessing steps such as peeling, blanching, etc.

The losses in quality of dried potato products can be

minimized by both pretreatment (adding some chem-

icals) before drying as well as optimizing the drying

conditions. Most of the information related to quality

of dried potato available in the literature is based on

the experiments carried out at the laboratory scale.

27.5.1 O

PTICAL

P

ROPERTY

Color (as an optical property) is a very important

quality attribute of dried potato products and is

subjected to appreciable changes during drying. One

of the most serious color problems is darkening that

occurs in potatoes during the production of dehy-

drated potato products. Enzymatic oxidation and

nonenzymatic (Maillard or browning) reaction are

most frequent causes for discoloration. The manifest-

ations in dehydrated potato dice are reddish-brown

discolored pieces in the dry state and dark discolored

soggy brown centers in the reconstituted state. It is a

limiting factor in determining maximum piece size

and drying rate. It has been shown that the rate

of color change increases as temperature increases

and air humidity decreases during conventional and

vacuum drying [20]. Most industries involved in the

manufacturing of dehydrated potato products use

sodium bisulfite as a source of sulfur dioxide to pre-

vent nonenzymatic browning in dehydrated potatoes.

Addition of sodium acid pyrophosphate (at a level of

0.1% based on potato solid) before drying prevents

discoloration in potato flakes.

The use of time-varying air temperature profiles

(sinusoidal and square wave) during drying of potato

pieces in a two-stage heat pump has shown to reduce

color change. Choy and coworkers [13] observed that

the overall color change in potato was minimum

when subjected to a higher varying dry temperature

(square waveform 358C, amplitude 58C, peak to val-

ley 108C, cycle time 60 min, drying time about 300

min). Other drying conditions were relative humidity

18.9%, absolute humidity 0.0087 kg/kg dry air, and

air velocity 2.4 m/s. The percentage reduction in over-

all color change for potato was 87%. The study sug-

gested that time-varying temperature drying in a heat

pump dryer process has potential for drying potato

products. Krokida et al. [21] studied the effect of

microwave drying on some quality properties of de-

hydrated potato. The study showed that microwave

and microwave–vacuum drying of potato resulted in

reduced color change compared to air-drying. The

color change of potato during drying can be minimized

by various types of pretreatments. Sulfite treatment,

blanching, osmotic and microwave pretreatments

have shown to reduce the color change significantly

during convectional drying of potato [22].

27.5.2 P

HYSICAL

P

ROPERTIES

Drying methods and conditions, sample size, and

shape have been shown to influence various physical

characteristics including structure, density, porosity,

shrinkage, and rehydration of dried potato products.

These are important properties characterizing the tex-

ture and the quality of the dried potato product.

Light microscopic studies of potato slabs (4.5

2.0

1.0 cm) during air-drying have revealed that

ß

2006 by Taylor & Francis Group, LLC.

shrinkage occurs first at the surface and then grad-

ually moves to the bottom with increase in drying

time. The cell walls become elongated. The degree of

shrinkage at a low drying temperature (408C) was

greater than at high temperature (708C). The surface

structure of potato slab is damaged in 1 h drying,

whereas the inner structure is apparently intact. As

drying proceeds, cracks are formed in the inner struc-

ture. When the interior structure finally dries and

shrinks, the internal stresses pull the tissue apart. The

dry material then contains numerous holes. Shrinkage

affects the density and porosity of dried potato. The

density at a given moisture content decreases with

increasing drying temperature [23].

McMinn and Magee [24] studied the air tunnel

drying (temperature 30 to 608C, velocity 1.5 m/s) of

potato. The results of their study indicated that in-

ternal porosity of potato cylinders first decreased with

drying time then it increased up to 10% at the end of

drying. The volume shrinkage exhibited a linear cor-

relation with respect to moisture content. The rate of

shrinkage during low-temperature drying was greater

than at high temperature and coefficient of rehydra-

tion increased to about 4% with increasing drying

temperature from 30 to 608C.

27.5.3 N

UTRITIONAL

P

ROPERTIES

Dehydrated potato products contain the same chem-

ical constituents as fresh potatoes, though their

amounts vary. The amount of dextrins in the dehy-

drated products is larger than in fresh potatoes. The

amount of sugars is less in dehydrated products than

that in the dry matter of fresh potato. The level of

cellulose decreases in the dehydrated products, by

100% on average, as compared to its content in the

dry matter of fresh potato. The total number of pectic

constituents changes slightly during processing.

A small amount of fat in fresh potato disappears

completely from dehydrated products. The protein

content in dehydrated products decreases as com-

pared to the dry matter content of fresh potato

tubers. The ash content in the dehydrated products

is also lower than that in raw potato. The vitamin

content in dehydrated potato products is very low in

comparison with fresh potato (Table 27.12).

27.6 SWEET POTATO AND OTHER ROOTS

Sweet potato is an important crop in many parts of

the world and is cultivated in more than 100 coun-

tries. As a world crop with 119 million tonnes pro-

duction per year, it ranks seventh from the viewpoint

of total production. It is fifth on the list of the devel-

oping countries as the most valuable food crops and

in monetary terms, it ranks 13th globally in the pro-

duction value of agricultural commodities. Like other

roots and tubers, the sweet potato has a high moisture

content of about 70%. The dry matter in sweet potato

consists of average 70% starch, 10% total sugars, 5%

total protein, l% lipid, 3% ash, 10% total fiber and rest

1% vitamins, organic acids, and other components.

Sweet potatoes are not only a moderately good en-

ergy source, but also contain significant quantities of

water-soluble vitamins ascorbic acid and thiamin, be-

sides supplying part of the daily requirement for ribo-

flavin and niacin. They also contain relatively higher

amounts of pyridoxine, folic acid, and pantothenic

acid [25].

27.6.1 D

RYING OF

S

WEET

P

OTATO

In traditional practice, the roots, which may or may

not be peeled, are sometimes cooked but more often

directly cut into pieces and spread out in the sun

to dry. The dried chips or slices may be only an

TABLE 27.12

Changes in Chemical Composition of Potato (Russet

burbank) after Processing

Constituents

a

Potato Products

Raw

Granule

b

Flake

b

Total solids (g)

20.8

14.2 (68)

16.9 (81)

Starch (g)

15.0

11.8 (79)

15.2 (101)

Total sugar (mg)

350

170 (49)

169 (48)

Reducing sugars (mg)

108

54.0 (50)

42 (37)

Total nitrogen (mg)

295

180.8 (61)

203 (69)

Protein (N

6.25) (g)

1.84

1.13 (61)

1.26 (3.5)

Free amino acid (mg)

12.5

7.1 (57)

6.8 (54)

Ascorbic acid (mg)

10.3

3.2 (31)

2.94 (29)

Riboflavin (mg)

0.014

0.006 (43)

0.003 (21)

Niacin (mg)

1.44

0.59 (41)

0.57 (40)

Thiamine (mg)

0.080

0.004 (5)

0.018 (23)

Magnesium (mg)

21.8

11.6 (53)

11.2 (51)

Calcium (mg)

9.4

7.1 (76)

5.4 (57)

Potassium (mg)

443

216 (49)

166 (37)

Sodium (mg)

16.9

17.8 (107)

28.4 (71)

Copper (mg)

0.11

0.03 (43)

0.04 (57)

Manganese (mg)

0.15

0.06 (40)

0.06 (40)

Zinc (mg)

0.19

0.14 (79)

0.15 (79)

Iron (mg)

0.37

0.22 (59)

0.30 (81)

a

100 g serving of each product.

b

Values in parentheses are the percentage of the constituents in raw

potato.

Source: From Lisinska, G., in: Potato Science and Technology,

Lisinska, G., Leszczynski, W., Eds., Elsevier Science Publishing

Co., Inc, New York, 1989, pp. 234–280.

ß

2006 by Taylor & Francis Group, LLC.

intermediate stage in the final production of other

products such as flour, snacks, starch, or alcohol. In

some cases, fresh sweet potatoes are soaked in 8–10%

salt solution for an hour before cutting and drying.

This practice is reported to inhibit microbial growth

during drying [26]. On a laboratory or commercial

scale, sweet potatoes are often treated with a solution

of sodium metabisulfite to inhibit enzymic browning,

discoloring finished product.

27.6.1.1 Sun and Solar Drying

In many countries including China and India, thou-

sands of tonnes of sweet potatoes are dried every year

in the form of chips or slivers by traditional sundry-

ing. The major part of this dried product is then sent

on to starch or alcohol factories for further process-

ing. Sundrying has various drawbacks including poor

control of energy input and product quality, as well as

frequent contamination by microorganisms, dust, and

insects. Methodology for the improvement of trad-

itional sundrying to produce a higher quality product

has been developed. Solar dryers with temperature

control, airflow regulation, and other technical innov-

ations have been designed to minimize the effects of

climatic changes, increase sundrying efficiency, and

improve product quality. A solar dryer, developed

by the International Potato Center, Lima, Peru, can

reduce the moisture content of cooked and shredded

sweet potatoes by about 45% in 18 h. Reorientation

to direct sunlight the following day dries the product

to about 10% moisture. A similar type of solar dryer

has been developed by the University of Hawaii,

Manoa, which can function directly with sunlight,

indirectly with solar-heated air, or in a combined

direct and indirect mode. The unit can also make

use of biogas during temporary unfavorable climatic

conditions. May and Chi [27] suggested partial drying

of sweet potato slices by immersion in a recirculating

concentrated sugar solution of 60–65% for several

hours before they are solar-dried.

27.6.1.2 Conventional Drying

Natural convectional dryer has been used in Philip-

pines to produce dried sweet potato. These dryers

utilize heat from burning the wastes. About 50 kg of

sweet potato chips of high quality are dried for 7–8 h.

Another form in which sweet potato is dried and

eaten as a dessert or snack is as an edible leather

also known as fruit roll or crush. In this preparation,

the flesh of sweet potato is cooked, mashed, and

sieved, mixed with 0.5% (w/w) carboxymethyl cellu-

lose (a binder), 200 ppm sodium bisulfite, and 7%

(w/w) sugar and formed into a sheet 1-mm thick,

which is oven-dried at 55 to 758C and 10–17% mois-

ture level. Samples dried at 758C were chewier than

those dried at lower temperatures. Samples were

crisper and crunchier when dried at 55 or 658C.

A

laboratory-scale

high-temperature

short-time

(HTST) pneumatic dryer has been fabricated in

India for the pretreatment before conventional drying

of sweet potato cubes [28]. Dried cubes produced by

this technique were of high quality in terms of poros-

ity, texture, and rehydration characteristics. Peeled,

cubed, and blanched sweet potatoes were subjected to

HTST pneumatic drying followed by conventional

cabinet drying to 5% moisture.

27.6.1.3 Industrial Drying

The production of high-quality flakes and other dried

sweet potato products may entail many unit oper-

ations at preprocessing and drying stages. Preheating

at preprocessing stage reduces enzyme discoloration

(polyphenolic oxidation) and peeling time. Steam

peeling is often used for removal of the skin. Peeling

with lye involves a 5–6 min exposure to 20% lye

solution for cured roots, and 3–6 min exposure to a

10% solution for freshly harvested roots, at 1048C

[29]. Peeling with superheated steam followed by

flash cooling by direct injection of cold water into

the peeler chamber increases the yields of peeled

sweet potato.

Flakes: After preprocessing, the roots are steamed,

crushed, and fed directly to a single-drum dryer heated

to 1208C. The dry film is then broken up into flakes. In

the United States, the preprocessed roots are pureed in

a pulper and screened through 0.8 mm mesh to remove

fibrous material. The puree is heated to 74–858C using

steam injection to gelatinize the starch and activate

amylolytic enzymes. This processing step results in a

consistently textured final product. Flash heating sub-

sequently inactivates the enzymes and completes the

cooking. The puree is then dried to 2–3% moisture on

steam-heated drum. Sodium acid pyrophosphate or

citric acid may be added to the puree before drying to

control nonenzymic browning to reduce discoloration

tendency of the reconstituted flakes.

Granules: In Japan, sweet potato granules are pro-

duced by the add-back process similar to that of

potato granules. In this process, roots are peeled,

steamed, crushed (moisture content 68%), dry gran-

ules added back (moisture content reduced to 35–

45%), conditioned, granulated, and flash-dried. The

granules can be used in croquettes or snack foods [25].

Diced, slices, or strips: The sweet potatoes are cut

into the requisite shapes and sizes. The cut pieces are

then blanched and dried into cabinet or tunnel dryers

at 40–708C with co- or countercurrent air circulation.

ß

2006 by Taylor & Francis Group, LLC.

Chips: For the manufacture of chips, sweet pota-

toes are peeled, boiled, or steamed for 30 min, mashed,

mixed with pea or cornstarch, salt, and monosodium

glutamate; mixture is pressed into paste and trans-

formed into rectangular shape. The strips are boiled

or steamed to gelatinize the starch, cooled, and cut into

slices of 1–2 mm thick. The slices are then dried and

packed as semifinished product. The semifinished

dried chips are fried before consumption.

Starch: Sweet potato has the advantage of remain-

ing as a high starch-producing crop with 30 and 49%

greater starch yield than rice, corn, or wheat, respect-

ively, under the same conditions. In China, at the

former level process, sweet potatoes are cut up by

hand, crushed by machine, and sieved to remove waster

such as peel and fiber. The starch is left to settle in a tank

and then removed. Water is added to the starch, which

is once more sieved and settled. Wet starch is trans-

ferred to jute bags and allowed to drip-dry for 1 d,

and air-dried outside at ambient temperatures [25].

27.6.1.4 Quality Changes

Sweet potato contains highly unsaturated lipids,

which are susceptible to oxidation. Sweet potato

flakes stored in air leads to strong hay-like off-odor,

loss of color, and undesirable decline in nutritional

value. The highly unsaturated nature of beta-carotene

and other carotenoids leads to their rapid oxidation

and consequent partial loss in flakes unless they are

stored in a reduced oxygen environment. The long

storage of dried sweet potato products will require

packaging in material, which excludes oxygen as well

as moisture. Darkening of uncooked slices and exces-

sive browning during frying results in discoloration in

the chips made from some cultivar. Blanching, in boil-

ing water or steam or in a solution of sodium acid

pyrophosphate, or dipping in sulfite solution helps to

prevent chip discoloration.

27.6.2 D

RYING OF

M

USHROOMS

Among the cultivated mushrooms, shiitake mush-

room (Lentinus edodes) is mainly dried and consumed

mostly by Orientals. The common mushroom (Agar-

icus) is mainly canned and consumed by Western

people. In Japan, consumption of dried shiitake is

always 20% higher than that of fresh shiitake. The

Japanese consumption of shiitake per capita is about

the same as that of Agaricus in European or North

American countries [30].

Sun and conventional drying: Some mushrooms

(Boletus luteus in Chile) are predried in Sun to about

15–20% moisture, held for a short time in temporary

warehouses, and then taken to a central drying plant.

The mushrooms are then fumigated, cleaned, and

sorted to remove dirt and foreign materials. The mush-

rooms are sliced, spread on tray, and tunnel dried. The

drying starts at low air temperature of 498C, which is

gradually increased to a final drying temperature of

718C and moisture is reduced to 10% [30].

White jelly fungus (Tremella fusiformis) grown in

China are dried and consumed as a drug or precious

food. Drying is usually done only by sun or by hot

air. The hot air-drying process takes up to 8 h and the

temperature is first held at 508C, then gradually de-

creased until it reaches 408C. Control of temperature

and a strong airflow are very important for the qual-

ity of dried product. The dried white jelly mushrooms

weigh only about 6–8% as much as fresh ones.

Industrial drying: Commercial drying of mush-

room involves soaking of mushroom in 0.05–0.1%

NaHSO

3

for 5–10 min before cutting into slices to

retard discoloration. Unblanched mushroom slices

dried at 40–508C result in light-colored products.

Drying temperature above this could cause browning

of the product. Light-colored dried mushroom can

also be obtained by drying at 40–458C at the begin-

ning and then raising the temperature gradually to

about 60–708C for 10 to 12 h. The most suitable

moisture content of mushroom for storage at room

temperature is in the range 6–8%. Freshly harvested

shiitake are dried in cabinet dryers to maintain good

flavor and the luster of the cap. The mushrooms are

dehydrated starting at 308C and the temperature is

then increased to 28C/h until a temperature of about

508C is reached (usually in 12–13 h). Finally they are

heated to 608C and held for 1 h to enhance the flavor

and bring out the luster of the cap [30].

Combined microwave and hot air drying experi-

ments have shown to greatly improve the structure

and bulk volume of dried mushrooms. However, the

geometry and dielectric properties of mushrooms are

such that potential for overheating of the center ham-

pers the application of this technology [31]. This was

overcome by osmotic pretreatment with sodium chlor-

ide solution and subsequently dried by application of

combined microwave and hot air drying. The results

showed that the mushrooms were heated more homo-

geneously. The rehydration properties and porosity of

dried mushrooms were also improved.

Quality and nutritional values: Mushrooms con-

tain large amounts of flavor and aroma producing

5’-ribonucleotides. Common mushroom (Agaricus)

contains about 50 mol and fresh shiitake mushroom

from 182 to 235 mol of 5’-nucleotides per 100 g fresh

weight as compared to vegetables, which contain 1 to

10 mol of these compounds per 100 g fresh weight.

The process of drying not only increases the shelf life

of mushrooms but also enhances the flavor with a

ß

2006 by Taylor & Francis Group, LLC.

unique taste. Guanylic acid has been identified as the

main constituent of the good taste of shiitake extract.

The increase of guanylic acid content is due to the

decomposition of ribonucleic acids by ribonuclease

during cooking at 60 to 708C. Lenthionine (C

2

H

4

S

5

)

has been identified in the aroma of shiitake mush-

rooms [30]. Studies have shown that the drying tem-

perature and time affected the retention of lenthionine

[32]. They proposed two-stage mechanism of forma-

tion and destruction of lenthionine during drying.

The first stage was formation of lenthionine and

other substances simultaneously; then lenthionine

was changed to other derivatives. At the second

stage, the mechanism that produced other substances

was terminated but the mechanisms that produced

lenthionine and the one that changed lenthionine to

other derivatives were continued. It was found that

the optimal condition was maintained at 708C and 9 h

and it retained the maximum amount of lenthionine

whereas the moisture content of dried mushrooms

was 13% (db). The Chinese believe that shiitake is

effective in the preservation of cerebral hemorrhage.

The Japanese researchers found that shiitake has abil-

ity to remove serum cholesterol and it has antitumor

activities [30].

Loch-Bonazzi et al. [33] evaluated the quality of

mushrooms dried by various processes such as hot

air, vacuum, freeze-drying in an adsorbent fluidized

bed and vacuum freeze-drying. Results of their study

indicated that vacuum freeze-dried products were of

superior quality in terms of density, rehydration cap-

acity, and color. They also reported that most flavor

compounds disappear during preparation and freez-

ing steps. Microwave–vacuum drying of mushroom

has been explored by Pappas et al. [34]. Their experi-

mental results indicated that microwave–vacuum dry-

ing exhibits superior drying performance as well as

improved rehydration characteristics.

27.6.3 D

RYING OF

P

EANUTS

Moisture content is the most critical factor in harvest-

ing, drying, storing, and marketing of peanuts. Pea-

nuts are normally between 35 and 50% moisture

content at digging. Molds that produce aflatoxin

grow best in peanuts between 12 and 35% moisture

content and between 26 and 388C. Peanuts are artifi-

cially dried to a moisture content to reach a safe

storage level of 7–8%. For marketing, the desired

moisture content of shelled peanuts is about 7.5%.

Some producers field-dry peanuts to 9% moisture to

avoid mechanical drying. This practice is unprofitable

because of the higher losses associated with dry vines,

stems, and pods. In Oklahoma, farmers have used

solar dryers (3 m wide, 1.8 m deep, 7.8 m long) for

peanut drying. The dryers constructed with wire mesh

sides and bottoms (0.9 m from ground) allowed the

air to circulate through entire load. The drying time

was 2–3 days for a batch of about 500 kg of freshly

harvested peanuts [35].

Mechanical drying of preanuts is usually carried

out in bin dryers. Peanuts are spread evenly over the

drying bin. The optimal drying air temperature for

peanuts is 358C. The relative humidity of drying air

should not be less than 55%. Higher capacity fan is

employed to ensure an airflow rate of approximately

900 m

3

air/h/m

2

drying area. Increasing temperature

to 438C increases the shelling operation. In case pea-

nuts are harvested above 35% moisture content, the

height of peanuts bed is kept around 0.6 m. The

moisture content of peanuts is frequently checked

during drying as peanuts approach the 12% moisture

level. This can be done by electronic moisture meters.

The heat is cut off when the peanuts reach 10–10.5%

moisture but fan is operated continuously until pea-

nuts are cooled, since drying will continue until an

equilibrium is reached between the kernel and shells.

No portion of batch should dry less than 7% and

more than 10% [35].

Quality considerations: In order to produce good

quality peanuts, the moisture removal rate is main-

tained at 0.5% per hour. Peanuts dried too rapidly or

stored at low moisture content will have a high per-

centage of split and bald kernels when shelled whereas

peanuts dried too slowly or stored at high moisture

content are more subjected to mold growth and afla-

toxin production. High-temperature drying is the

major cause of bad flavors in peanuts [35].

27.6.4 D

RYING OF

G

INSENG

Ginseng is a herbaceous perennial plant in the Aralia-

ceae family, which has been used for thousands of

years to cure or prevent a large number of ailments.

One of its most recognized roles is as an adaptogen, a

herb that strengthens body’s defences against stress.

Ginseng is native to China, Korea, Russia, and some

areas of North America. It contains vitamins A, B-6,

and the mineral zinc, which is claimed to help in the

production of thymic hormones necessary for proper

functioning of the defence system. The primary active

ingredients of ginseng are more than 25 saponin glyco-

sides called ‘‘ginsenosides.’’ It is noteworthy that the

American ginseng is different from the Asian variety in

both physical and chemical characteristics.

The principal measures of quality of ginseng root

are the contents of ginsenosides and polysaccharides,

which are a mixture of complex sugars. The quality of

the root depends on the production practices followed

by the growers as well as postharvest processing,

ß

2006 by Taylor & Francis Group, LLC.

e.g., drying of the root [36]. Root age as well as size

and shape are said to affect the ginsenoside content.

The quality is said to be best at the root age of 6–7

years for Korean ginseng. There are also some var-

ieties of the Korean ginseng, e.g., white and red gin-

seng. According to Chang et al. [37], red ginseng is

among one of the most expensive agricultural prod-

ucts, fetching some US$3000 for a 600 g package of

ten red ginseng roots for the premium heaven grade

to just under US$400 for the low end ‘‘good’’ grade in

Korea (figures for 2000).

Raw ginseng upon harvesting must be processed

and dried in a short time to prevent spoilage. The

postharvest-processing steps include cleaning, trim-

ming of small lateral roots, washing, peeling (op-

tional), drying, grading, and packaging. The market

value depends on color, size, maturity, and shape.

It is important to dry the roots carefully to obtain

high-value-added ginseng.

The initial moisture content of ginseng is about

70–80% wet basis. The optimal final moisture content

for storage is about 12–13% wet basis [37]. Diametral

shrinkage of about 20–30% has been reported as a

result of drying. Typically the roots are dried in con-

vectional dryers using air temperatures of 32 to 388C.

Park et al. [38] proposed a new combined infrared

(IR) and convectional dryer for ginseng roots and

found that the presence of infrared affected the

color of the root but did not affect the final quality

of the product in terms of its chemical content.

Freeze-dried root gives the highest quality but it is a

slow and expensive process. The ginsenoside content

may be reduced by over 25% by drying the root using

448C air instead of 388C. Internal color also darkens

with increase in drying air temperature. As all the

moisture is internal and hence in the falling drying

rate period it is not necessary to use high airflow rates

in the dryer. It is important to expose all drying

surfaces uniformly to the drying medium to avoid

over- or underdrying of the roots in the batch.

27.7 SUMMARY

An overview is provided for commercial drying prac-

tices used in the manufacturing of various potato-based

products. Drying practices for other roots such as sweet

potato, mushroom, peanuts, ginseng, and tobacco have

also been mentioned briefly. In general, the technology

related to convectional drying is well established

whereas other methods are still under investigation.

Microwave drying is used mostly as finish drying oper-

ation. Osmotic drying may find its place as a pretrea-

ment method for reducing drying load on conventional

dryers and for improving color of final product.

REFERENCES

1. WF Talburt, in: Potato Processing, 4th ed., WF

Talburt, O Smith, Eds., An AVI Book by Van

Nostrand Reinhold Company, Inc., New York, 1987,

pp. 1–9.

2. CM McCay, JB McCay, O Smith, in: Potato Process-

ing, 4th ed., WF Talburt, O Smith, Eds., an AVI Book

by Van Nostrand Reinhold Company, Inc., New York,

1987, pp. 287–332.

3. TG Smith, CC Huxsoll, in: Potato Processing, 4th ed.,

WF Talburt, O Smith, Eds., an AVI Book by Van

Nostrand Reinhold Company, Inc., New York, 1987,

pp. 333–369.

4. BS Luh, JG Woodroof, Commercial Vegetable Process-

ing, The AVI Publishing Company, Inc., Westport,

CT, 1975.

5. JL Heid, MA Joslyn, Fundamental of Food Processing

Operations, The AVI Publishing Company, Westport,

CT, 1967.

6. JJ Kelly, in: Handbook of Industrial Drying, AS Mujum-

dar, Ed., Marcel Dekker, New York, 1987.

7. MJ Willard, VM Hix, G Kluge, in: Potato Processing,

4th ed., WF Talburt, O Smith, Eds., an AVI Book by

Van Nostrand Reinhold Company, Inc., New York,

1987, pp. 557–612.

8. JG Moore, in: Handbook of Industrial Drying, AS

Mujumdar, Ed., Marcel Dekker, New York, 1987.

9. G Lisinska, W Leszczynski, Potato Science and Tech-

nology, Elsevier Science Publishing Co., Inc., New

York, 1989, pp. 281–346.

10. RH Treadway, in: Potato Processing, 4th ed., WF

Talburt, O Smith, Eds., an AVI Book by Van Nostrand

Reinhold Company, Inc., New York, 1987, pp. 647–

663.

11. S Grabowski, AS Mujumdar, in: Drying of Solids,

International Science Publisher, New York, 1992,

pp. 303–325.

12. MR Ravindra, PK Chattopadhay, J Food Eng 44: 5–11,

2000.

13. CK Jon, AS Mujumdar, CS Kiang, HJ Choy, MNA

Hawaldar, in: Drying Technology on Agriculture and

Food Science, AS Mujumdar, Ed., Science Publishing,

Inc., Enfield, NH, 2000, pp. 213–251.

14. O Smith, in: Potato Processing, 4th ed., WF Talburt,

O Smith, Eds., an AVI Book by Van Nostrand Rein-

hold Company, Inc., New York, 1987, pp. 371–489.

15. R Blau, M Powell, JE Gerling, Proc Prod Tech Div

Meetings, Potato Chip Inst Intern, 1965, pp. 1–8.

16. CM Olsen, CL Drake, in: Proc Prod Tech Div Meetings,

Potato Chip Inst Intern, 1966, pp. 51–54.

17. C Ratti, AS Mujumdar, in: Handbook of Industrial

Drying, AS Mujumdar, Ed., Marcel Dekker, New

York, 1995, pp. 567–588.

18. TM Afzal, T Abe, J Food Eng 37: 353–365, 1998.

19. TM Afzal, T Abe, Drying Technol 17(1&2): 137–155,

1999.

20. MK Krokida, VT Karathanos, ZB Maroulis, J Food

Eng 35: 369–380, 1998.

ß

2006 by Taylor & Francis Group, LLC.

21. MK Krokida, CT Kiranoudis, ZB Maroulis, J Food

Eng 40: 269–277, 1999.

22. M Krokida, Z Maroulis, in: Drying Technology on

Agriculture and Food Science , AS Mujumdar, Ed., Sci-

ence Publishing, Inc., Enfield, NH, 2000, pp. 61–105.

23. N Wang, JG Brennan, J Food Eng 24: 61–76, 1995.

24. WAM McMinn, TRA Magee, J Food Eng 33: 37–48,

1997.

25. JA Woolfe, in: Sweet Potato, An Untapped Food Re-

source, Cambridge University Press, Cambridge, 1992.

26. FG Winaro, in: Proceedings of the First International

Symposium, RL Villareal, TD Griggs, Eds., AVRDC,

Shanhua, Tainan, 1982, pp. 373–384.

27. JH May, SPS Chi, in: Sweet Potato: Proceedings of the

First International Symposium , RL Villareal, TD Griggs,

Eds., AVRDC, Shanhua, Tainan, 1982, pp. 429–437.

28. KS Jayaraman, VK Gopinathan, P Pitchamuthu, PK

Vijayaraghavan, J Food Technol 17(6): 669–678, 1982.

29. SJ Kays, in: Sweet Potato Products: A Natural Resource

for the Tropics, CRC Press, Boca Raton, FL, 1985,

pp. 205–218.

30. BK Wu, in: Encyclopedia of Food Science and Technol-

ogy, Vol. 3, YH Hui, Ed., John Wiley & Sons, New

York, 1992, pp. 1844–1848.

31. E Torringa, E Esveld, I Scheewe, RVD Berg, P Bartels,

J. of Food Engineering 49: 185-191, 2001.

3 2 . N R attanasomboon, S Bhumiratana, T Yoo vidhya,

km utt.ac.th/organization/ Engine ering/ Food/t014 y94

, 1994.

33. CL Loch-Bonazzi, E Wolff, H Gilbert, Food Sci Tech-

nol (LWT), 25: 334–339, 1992.

34. C Pappas, E Tsami, D Marinos-Kouris, Drying Technol

17(1–2): 157–174, 1999.

35. JG Woodroof, in: Peanuts: Production, Processing,

Products, 3rd ed., JG Woodroof, Ed., AVI Publishing

Company, Inc., Connecticut, 1982, pp: 91–119.

36. JA Duke, Ginseng: A Concise Handbook, Reference

Publications, Inc., Algonac, MI, 1989, pp. 103.

37. DI Chang, SH Bahng, YH Chang, HY Kang, Devel-

opment of a new model drying system for high yield og

heaven grade ginseng, in: Proceedings of 3rd Inter-

national Conference on Agricultural Machinery Engin-

eering, Vol. II, Seoul, Korea, 2000, pp. 370–377.

38. SJ Park, SM Kim, MH Kim, CS Kim, CH Lee, Quality

of Korean ginseng dried with a continuous proto-type

continuous flow dryer using far infrared and heated air,

Proceedings of 3rd International Conference on Agricul-

tural Machinery Engineering, Vol. II, Seoul, Korea,

2000, pp. 388–395.

39. W Leszczynski, in: Potato Science and Technology,

G Lisinska, W Leszczynski, Eds., Elsevier Science Pub-

lishing Co., Inc, New York, 1989, pp. 11–128.

40. JM Aguilra, J Chirife, JM Flink, M Karel, Lebensm

Wissen und-Technol 8: 128, 1975.

41. S Alzamora, Thesis, Universedad de Buenos Aires,

Argentina, 1979.

42. V Gekas, I Lamberg, J Food Eng 14: 317–326, 1991.

43. MN Islam, JM Flink, J Food Technol 17: 373–385, 1982.

44. CT Kiranoudis, ZB Maroulis, D Marinos-Kouris, Int J

Heat Mass Trans, 38: 463–480, 1995.

45. JC Lawrence, RP Scott, Nature 210: 301–303, 1966.

46. KCAM Luyben, JJ Olieman, S Bruin, Drying ’80, Vol.

2, AS Mujumdar, Ed., 1980, pp. 233–243.

47. A Mulet, J Food Eng 22: 329–348, 1994.

48. T Ronald, A Magee, PD Wilkinson, Int J Heat Mass

Trans 27: 541–549, 1992.

49. GD Saravacos, SE Charm, Food Technol 16(1): 78–81,

1962.

50. CO Rovedo, C Suarez, P Viollaz, J Food Eng 36:

211–231, 1998.

51. GD Saravacos, J Food Sci 32: 81–84, 1967.

52. GD Saravacos, R Stinchfield, J Food Sci 30: 779–786,

1965.

53. RN Biswal, LR Wilhelm, A Rojas, JR Mount, Trans

ASAE 40: 1383–1390, 1997.

54. HA Iglesias, J Chirife, Food Sci Technol 9: 107–113,

1976.

55. TP Labuza, in: Moisture Sorptions: Practical Aspects of

Isotherm Measurement and Use, American Association

of Cereal Chemists, St. Paul, MN, 1984.

56. M Karel, in: Water Relations of Foods, RB Duckworth,

Ed., Academic Press, New York, 1975.

57. CJ Lomauro, AS Bakshi, TP Labuza, Food Sci Technol

18: 118–124, 1985.

58. N Wang, JG Brennan, J Food Eng 14: 269–287, 1991.

59. CP McLaughlin, TRA Magee, J Food Eng 35: 267–280,

1998.

60. AM Bianco, G Boente, ML Pollio, SL Resnik, J Food

Eng 47: 327–331, 2001.

61. HA Iglesias, J Chirife, in: Handbook of Isotherms, Aca-

demic Press, New York, 1982.

62. CT Kiranoudis, ZB Maroulis, E Tsami, D Marinos-

Kouris, J Food Eng 20: 55–74, 1993.

63. MA Rao, J Barnard, JF Kenny, Trans ASAE 18(6):

1189–1192, 1975.

64. JP Gratzek, RT Toledo, J Food Sci 58: 908, 1993.

65. G Donsi, G Ferrari, R Nigro, J Food Eng 30: 263–268,

1996.

66. I Lamberg, B Hallstrom, J Food Technol 21: 577–585,

1986.

67. HE Stewart, BE Farkas, SM Blankenship, MD Boy-

ette, Int J Food Prop 3: 433–457, 2000.

68. ASHARE, in: Fundamentals Handbook, An American

Society of Heating, Air conditioning and Refrigeration

Engineers, New York, 1967.

69. HD Chang, LC Tao, J Food Sci 46: 1493–1497, 1981.

70. WO Ordinanz, Food Ind 18: 101, 1946.

71. F Stitt, EK Kennedy, Food Res 10: 426–436, 1945.

72. N Wang, JG Brennan, J Food Eng 19: 303–310, 1993.

73. K Hayakawa, J Succar, Food Sci Technol 16: 373–375,

1983.

74. J Andrieu, E Gonnet, M Laurent, in: Food Engineering

and Process Applications, Vol. I, M Le Maguer, P Jelen,

Eds., Elsevier Applied Sciences, London, 1985.

75. JJ Gaffney, CD Baird, WD Eshleman, ASHRAE Trans

86: 261–280, 1980.

76. G Lisinska, in: Potato Science and Technology,

G Lisinska, W Leszczynski, Eds., Elsevier Science Pub-

lishing Co., Inc, New York, 1989, pp. 234–280.

77. S Sokhansanj, DS Jayas, in: Handbook of Industrial

Drying, AS Mujumdar, Ed., Marcel Dekker, New

York, 1987.

ß

2006 by Taylor & Francis Group, LLC.

Document Outline

- Table of Contents

- Chapter 027: Drying of Potato, Sweet Potato, and Other Roots

Wyszukiwarka

Podobne podstrony:

Microwave drying characteristics of potato and the effect of different microwave powers on the dried

[Mises org]Mises,Ludwig von The Causes of The Economic Crisis And Other Essays Before And Aft