2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Winckelmann-Feier 2004

Am 02. 12. 2004 fand erstmals seit langer Zeit

wieder eine Winckelmann-Feier des Deutschen

Archa¨ologischen Instituts in der Residenz des

deutschen Botschafters in Teheran statt. Damit

knu¨pfen wir an eine Tradition an, die seit der

Gru¨ndung der Abteilung Teheran 1961 bestand

und bis 1982 fortdauerte. Die Winckelmann-Feier

erinnert an Johann Joachim Winckelmann, einen

der Gru¨ndervater der klassischen Archa¨ologie,

und findet anla¨sslich seines Geburtstags am

9. Dezember 1717 statt.

Der Anstoß zur Wiederaufnahme dieser Tradi-

tion ging vom deutschen Botschafter, Paul Freiherr

von Maltzahn, aus. Es war auch sein Vorschlag,

die Winckelmannf-Feier in den Ra¨umlichkeiten

der deutschen Residenz stattfinden zu lassen,

die einen festlichen Rahmen fu¨r diese Veranstal-

tung bietet.

Die Winckelmann-Feier soll auch in Zukunft

ein Schaufenster auf die Arbeiten deutscher

Forscher in Iran bieten. Zum Auftakt wurde mit

dem

diesja¨hrigen

Festvortrag

von

Barbara

Helwing die deutsch-iranischen Ausgrabungen

in Arisma¯n, der ersten Ausgrabung mit Beteili-

gung ausla¨ndischer Forscher seit 1979, vorge-

stellt.

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Early mining and metallurgy on the western Iranian Plateau:

First results of the Iranian – German archaeological

research at Arisma¯n, 2000–2004

By Barbara Helwing

The detection of metal is no doubt one of the cru-

cial steps in human history. Metal is a malleable

material that can easily be shaped into different

forms. Metal artifacts are flexible and tough.

Blades and working edges can be resharpened

continuously. And when eventually a metal tool

breaks, the object can be remelted and the mate-

rial recycled. Hence, metal enabled man for the

first time to produce tools and weapons with an

efficiency unknown until then.

Christian Jurgensen Thomsen was the first to

recognize the importance of the material metal

as early as the 1830’s. Based on the major mate-

rial used for the production of cutting tools, he

proposed a classification system for the archaeo-

logical collection of the Copenhagen Museum in

1836. It is, hence, to him that we owe the classic

division of human history into three major peri-

ods: the Stone, Bronze and Iron Age

1

.

More than one and a half centuries of archae-

ological research have passed since the days of

Thomsen. Cultures and civilizations have been

brought to light. Cities with palaces and temples

have been unearthed. Written documents have

been discovered, deciphered and read so that

regional histories could be written. Therefore, we

now possess a much better knowledge of prehis-

tory than Thomsen did in his days.

And yet, the invention of metalworking still

marks a critical point in culture history. As,

amongst many others, another pioneer of prehis-

toric research, Vere Gordon Childe, pointed out

in many of his writings

2

, the invention of metal

working is directly linked to the development of

complex societies with administration, labor divi-

sion and long distance trade networks, to name

only a few. Therefore, the origins of metallurgy

have long been – and still are – one of the top

priority research topics worldwide.

In Mesopotamia, often called the “cradle of civi-

lization”

3

or the “heartland of cities”

4

, the emer-

gence of a complex metallurgy is attested during

the 4

th

–3

rd

millennium BC. But where and how

did these early steps in the development of me-

tallurgy take place? Where were the sources that

provided an emerging industry with the necessary

raw materials? How was that material extracted,

processed and – last but not least – circulated?

And what were the repercussions of the develop-

ment of a professional metal industry on the com-

munities involved?

The lack of natural resources in the Mesopota-

mian heartland is a well-known fact

5

. Besides

many other resources, metal ores are absent in

the alluvial plain. Hence, the quest for raw mater-

ials has long been seen as one of the major trig-

gers for the development of long distance con-

tacts by trade or colonization. Metal ores are,

however, abundant in the mountain ranges that

surround the lowland to the Northeast and West.

Those mountain chains, the Taurus and Za¯gros

ranges, are part of the much larger Alpidic forma-

tion that stretches from the Alps in Europe to the

Himalayas in southern Asia. Extensive erosion,

enhanced by the location at the transition be-

tween arid and humid environments, volcanism

and continuous tectonic activity have helped here

to expose rich ore mineralizations. The subse-

quent weathering of the ore bodies has yielded

highly attractive colored copper ores such as ma-

lachite that can be detected easily. It is only nat-

ural that experiments with new materials should

have been carried out in close proximity to the

place where they originate.

Over the past decades, several research pro-

jects have been conducted that are aimed at the

understanding of early metallurgy in Greater Me-

sopotamia. Among them are the Mesopotamian

Metals Project conducted at the University of

Pennsylvania

6

, the restudy of the Susa objects

combined with scientific analysis at the Louvre

Museum

7

, The Early Metals in Mesopotamia pro-

ject based at Heidelberg

8

, different projects car-

ried out by the German Mining Museum (Bochum)

in the Levant

9

and on the Arabian Peninsula

10

,

geological and mining archaeological prospecting

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

1

Thomsen 1837.

2

Childe 1944; Childe 1948 (1936).

3

Kramer 1967.

4

Adams 1981.

5

Algaze 1993.

6

Stech 1999.

7

Tallon 1987.

8

H. Hauptmann/Pernicka 2004.

9

Weisgerber/A. Hauptmann 1988; A. Hauptmann 2000.

10

Weisgerber 1980; Weisgerber 1981.

by the Max-Planck-Institute for Nuclear Physics

in Anatolia

11

and the excavations carried out by

the Oriental Institute Chicago at Kestel in Tur-

key

12

.

These projects approach the topic of metal-

lurgy from three different angles: The first is the

analysis of the archaeological metal objects prop-

er, distinguishing their basic metals and trace ele-

ments and details of their technology. A second

possibility is the documentation of ore deposits

and traces of mining activities combined with an

analysis of metallurgical finds. And as a third ap-

proach excavations are carried out in ancient

mines and miners’ settlements.

Thus far, this research has covered mainly Tur-

key, Iraq, the Levant and the Arabian Peninsula,

so that we are sufficiently well informed about ore

deposits, mines and artifacts from these areas.

However, one large and important area is almost

completely missing – Mesopotamia’s nearest

neighbor, Iran. The Iranian highlands possess

one of the largest concentrations of metal ore de-

posits both of copper and of silver and lead

13

,

and, thus, it is not surprising that these have

been exploited from early times onwards. Some

of the earliest metal artifacts known to date origi-

nate from Neolithic sites on the Iranian plateau.

Among the earliest are beads made from cold-

worked, rolled copper sheet found at Neolithic Ali

Kosh

14

and copper awls and copper prills from

Tepe Zagheh

15

and Choga Sefid. From the follow-

ing Chalcolithic period, metal artifacts were found

in Tappe Hesar

16

, Tappe Sialk

17

and Susa

18

. And

even metallurgical workshops are known, for ex-

ample from the early 4

th

millennium BC Tappe

Qabresta¯n

19

, where crucibles, moulds for casting,

and artifacts were excavated. All of these finds

are amongst the earliest of their kind. It seems

indeed that Iran, or more precisely the Iranian

highlands, played a crucial role in the develop-

ment of one of the most important technologies

of mankind.

Early steps into archaeometallurgical research

in the Iranian highlands were undertaken by some

of the pioneers of the discipline. An initial field ex-

pedition was led by Theodore Wertime in the

1960s to investigate ancient mining sites in the

central and southeastern part of the country

20

.

Copper mines were also documented in the vici-

nity of Vesˇna¯ve, close to Qom

21

, and in particular

the mining district of Nakhlak-Anarak was visited

by various researchers

22

. Analysis of the metal

finds from Susa was carried out in the 1970s by

Thierry Bertoud, who suggests that the raw mate-

rial most probably stems from a source on the

Iranian plateau, possibly from Anarak

23

. How-

ever, these early steps in research could not be

followed up by more detailed programs.

Answers to the questions on the Where and

How of early metallurgy are now being sought by

a new multi-disciplinary research project that fo-

cuses on metallurgical activities in the western

part of the Central Iranian Plateau. This project,

entitled Early Mining and Metallurgy on the

Central Iranian Plateau, is designed as a joint

project by the Iranian Cultural Heritage and Tour-

ism Organization (ICHTO), the German Archae-

ological Institute, the Geological Survey of Iran,

the German Mining Museum in Bochum and the

Department of Archaeometry of Freiberg Univer-

sity and is intended to cover all aspects of metal-

lurgy throughout prehistory.

The study area comprises the western part of

the Iranian Plateau, delimited by the Za¯gros Moun-

tains to the southwest and the Alborz Mountains to

the north. Work concentrates on a wide corridor

that extends in northwest-southeast direction,

north of the northernmost Zagros chain, the Karkas

(vulture) Mountains, and runs parallel with these.

Within this area, the best known archaeological

site is Tappe Sialk in Ka¯sˇa¯n, which was investi-

gated during the 1930s by a French mission di-

rected by Roman Ghirshman

24

and is again un-

der investigation under the direction of Dr. Malek

Shahmirzadi since 2001

25

. The prehistoric site of

Arisma¯n

26

, the focus of this lecture, is located about

60 km southeast of Ka¯sˇa¯n and Tappe Sialk.

The study program of the interdisciplinary re-

search project comprises a series of related lines

of inquiries. These are:

– geological prospections for metal ore deposits

in western Central Iran

– chemical analysis of the metal ores and their

geochemical “fingerprinting”

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

11

Wagner/ztunalı 2000.

12

Yener et al. 1989;Yener/Vandiver 1993.

13

Momenzadeh 2004.

14

Smith 1969.

15

Negahban 1977; Sto¨llner et al. 2004, 601 Kat. No. 88.

16

Pigott 1989.

17

Ghirshman 1938; Smith 1968.

18

Tallon 1987.

19

Majidzadeh 1979.

20

Smith et al. 1967; Wertime 1967; Wertime 1968.

21

Holzer/Momenzadeh 1971.

22

Bazin/Hu¨bner 1969.

23

Berthoud et al. 1976; His analysis have been carried out

with methods that today are outdated and would urgently re-

quire a reconsideration.

24

Ghirshman 1938.

25

Malek Shahmirzadi 2002; Malek Shahmirzadi 2003; Malek

Shahmirzadi 2004.

26

Chegini et al. 2000;Chegini et al. 2004.

Barbara Helwing

426

– mineralogical analysis of the metal ores

– the investigation of ancient mining traces and

the excavation of exemplary Bronze Age cop-

per mines at Vesˇna¯ve near Qom

– archaeological surveying around the mining

and industrial sites in order to understand the

regional settlement system

– the exemplary excavation of a metal producing

center of industrial scale, dating to the 4

th

to

3

rd

millennium B.C. at Arisma¯n near Ka¯sˇa¯n,

close to the famous prehistoric site of Tappe

Sialk

– the geochemical analysis of copper slags and

of copper artifacts from these new excavations

in order to understand their composition and to

match them with the sources of raw materials

– palaeoenvironmental studies in order to recon-

struct the ancient vegetation cover and climate

as well as the impact of metallurgical activities

on the environment; metallurgical smelting re-

quires enormous amounts of fuel that had to

be procured in the vicinity

– archaeo- and anthropological investigations

into the transformation of society that must

have necessarily occurred in connection with

the development of industrial scale metallurgy

– tracing marketing places and trade routes to

better understand the regional settlement sys-

tem and the integration of the industrial centers

into a system of long distance exchange

By combining the results of these different lines

of investigation, it will become possible to provide

new insight into the complex interrelationship of

mining sites, metal processing workshops and

trading centers.

As part of the Research Project on Early

Mining and Metallurgy on the Central Iranian

Plateau, the Iranian Cultural Heritage and Tour-

ism Organization and the German Archaeological

Institute began archaeological excavations in

Arisma¯n in 2000.

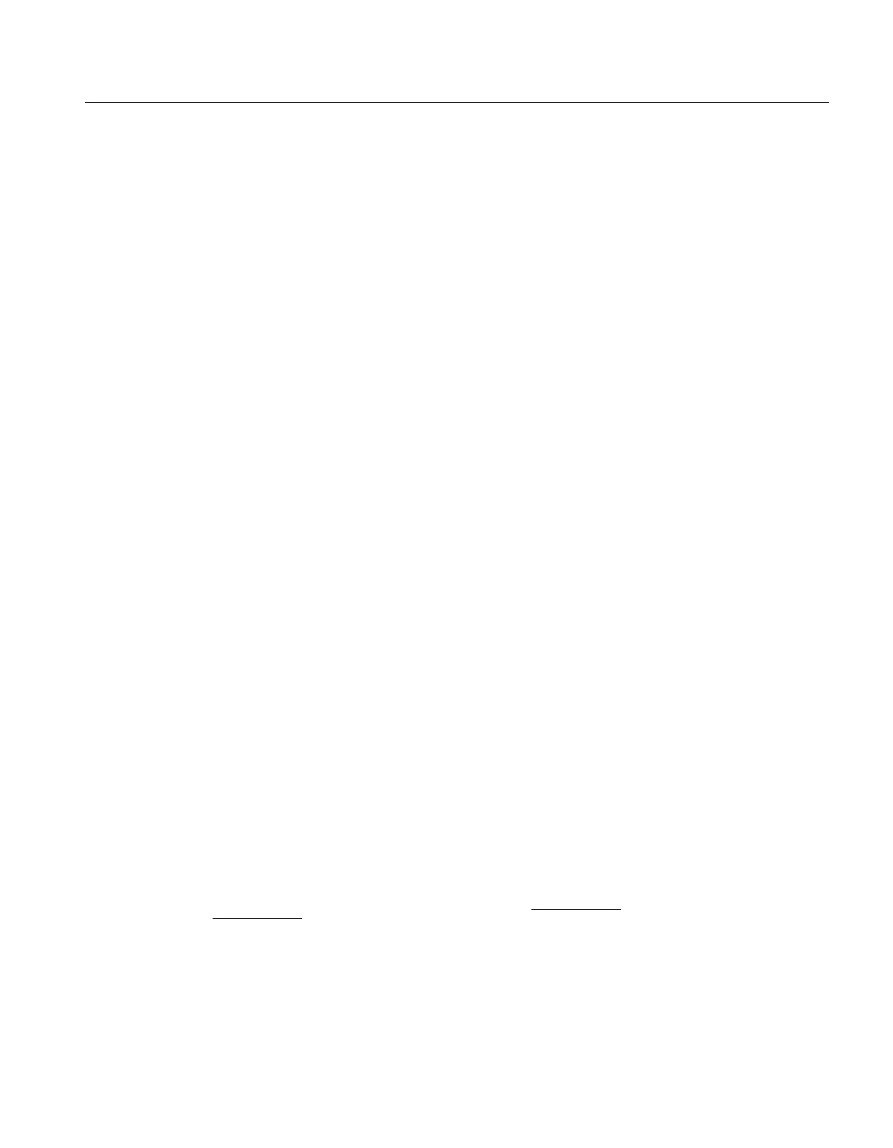

The site (Fig. 1; 2) is located on the lowermost

slopes of the 4000 m high Karkas mountains, at

the transition from the slopes to the plain, at an

elevation of 1000 m asl. On the immediate fringe

of the Dasˇt-e Kavir the environment is arid with

about 500 mm of precipitation in normal years.

The site was discovered due to an enormous

accumulation of blackish slag fragments on the

surface, associated with prehistoric pottery that

can be compared to the period III–IV material

from Tappe Sialk. Traces of prehistoric occupation

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Fig. 1

Arisma¯n. View of the

site from the north,

Karkas mountains

are visible in the

background.

Early mining and metallurgy on the Western Iranian Plateau

427

extend over an area of more than one square

kilometer. Three major occupation areas could be

distinguished, designated Arisma¯n 1–3 subse-

quently. Occupation during the 5

th

to 3

rd

millennia

is attested in Arisma¯n 1 and 3, while Arisma¯n 2

yielded mainly grey polished ware of the later 2

nd

millennium. In Arisma¯n 1, cultural layers do not

exceed 1.60 m, making a regular shifting of the

settlement highly probable. Three huge slag

heaps of c. 25 m diameter form part of the site.

Excavations have been carried out in five

areas: in two of the slag heaps in areas A and D,

remains of late 4

th

to early 3

rd

millennium BC

(Sialk IV) metallurgical activities were found,

while the third, much smaller slag heap E yielded

no structural remains related to metallurgy. Area

B in the southern part of the site revealed Sialk

III (mid 4

th

millennium BC) pottery workshop

areas. A domestic quarter with integrated work-

shops contemporary to the slag heaps was un-

covered in the northern part of the site in area C.

In area B, four trenches of 9 by 9 m extension

have been excavated so far. The earliest settle-

ment layers that were reached consist of a do-

mestic house of the late Sialk III culture. This

house is constructed of pise´ and has a floor

made of beaten earth. The house is fully equipped

with ovens and kitchen facilities and some pottery

was found in situ next to the oven – apparently

some kitchen ware and quite archaic in appear-

ance. The surface of the base of one of the large

vessels is completely covered with finger impres-

sions – possibly a means to increase the overall

surface of the vessel.

At a later stage of Sialk III, this area was

turned into a professional pottery workshop area.

Pottery kilns were dug into the settlement re-

mains, and an ash layer corresponding to the kiln

phase yielded several hundreds of similar ves-

sels, probably belonging to one charge of a kiln.

Two different types of ovens have been found:

one type is represented by large ovens with a

key-hole shaped outline and a central pillar. This

key-hole shaped oven is embedded about 1 m

into the ground. The walls were plastered and

must have experienced high temperatures, since

the wall plaster is partly slagged. One single ves-

sel – a small stemmed jar with geometric painted

design – was found inside the kiln.

Concerning the kiln’s reconstruction

27

, it is

highly probable that flat clay slabs were placed in

a radial arrangement on top of the central pillar.

Fragments of flat clay slabs have been found.

They have a straight outer edge, but no right an-

gles, indicating that the original form was subrec-

tangular. Free space left between the clay slabs

would then have allowed the heat from the fire

below to enter the firing chamber. The upper part

of the kilns is not preserved, but must probably

be reconstructed as a vault. This may have been

a temporary construction that needed rebuilding

for every single firing.

The second type of pottery kiln is represented

by two examples in area B 35, kilns 23 and 26.

These kilns (Fig. 3) are approximately oval and

smaller, measuring about 90 cm in diameter.

They do not rely upon a central support, instead

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

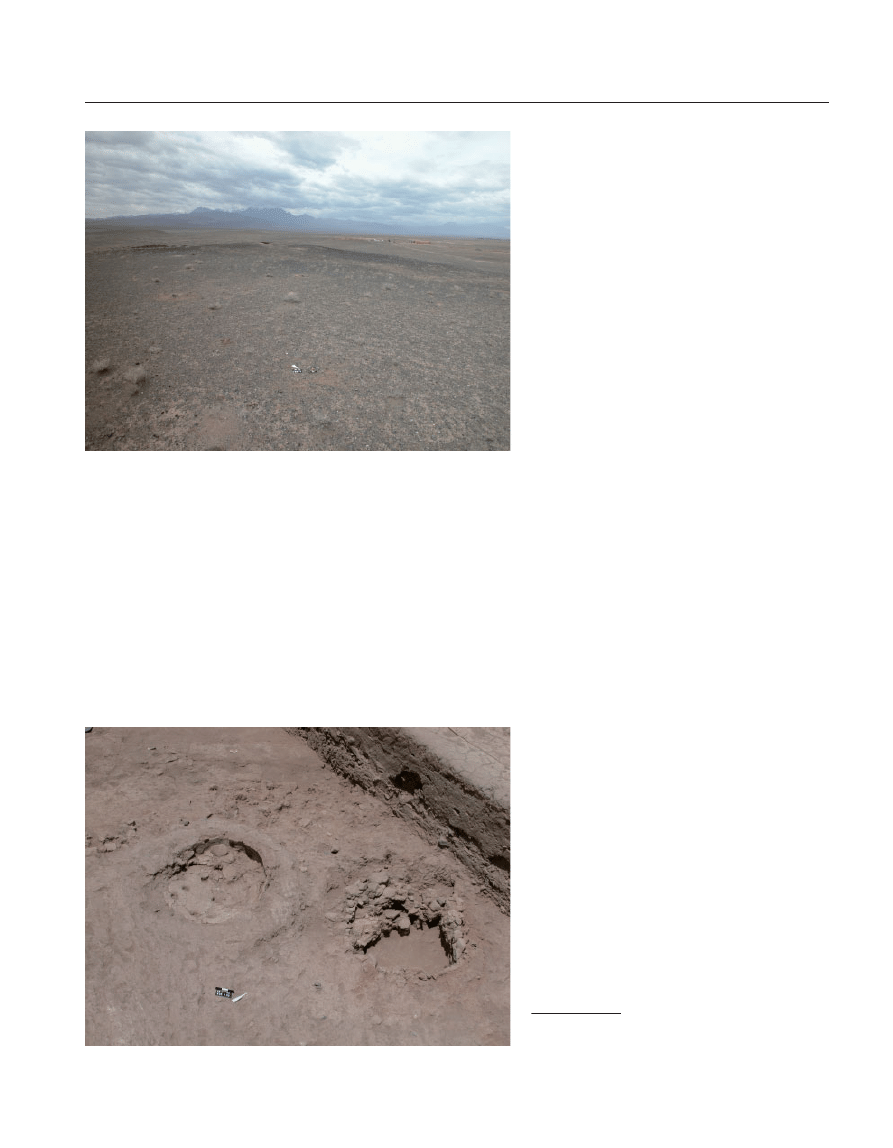

Fig. 2

Arisma¯n. Black slag

heap in area D.

Fig. 3

Arisma¯n.

Area B, pottery kilns

of Sialk III period

(mid 4

th

mill. BC).

27

A comprehensive discussion and reconstruction is proposed

by N. Boroffka/Becker 2004.

Barbara Helwing

428

the bottom is formed by a flat clay slab with holes

at regular intervals. This slab rests upon small

buttresses around the wall of the kiln.

Similar kilns have been found in Tappe Sialk in

layer III,1

28

. These kilns were fired from below

and the heat would enter the firing chamber

through the holes in the clay slab. According to

Abbas Alizadeh

29

, the upper part of the kiln must

again be reconstructed as a vault.

Pottery

30

was found in large quantities in a

layer of debris with pottery production wasters,

thus allowing for a general classification of the

material: vessels are mainly produced from a fine

mineral clay that turns mostly buff, or sometimes

greenish or reddish when fired. Brown paint is

applied to this light ground, mostly in geometric

patterns. Characteristic shapes comprise beakers

and chalices, mostly with a stemmed base, and

also large vessels. The large number of similar

vessels found in Arisma¯n area B is a good indica-

tor of the scale and professionality of pottery pro-

duction at the site. The firing of pottery took place

under close surveillance, which demonstrates the

high level of pyrotechnology – the use of fire to

produce high temperatures in order to alternate

the chemical properties of material –, as well as

an attentiveness that is no doubt one of the pre-

conditions for the development of a prospering

metal production.

Zoomorphic and anthropomorphic motifs also

appear on pottery, but less frequently. All kinds of

animals with horns – stags, goats, cattle and

deer – are depicted, as are waterfowl and, rarely,

humans. These depictions provide some clues

about the ancient environment at Arisman; the in-

habitants were clearly familiar with these animals.

According to the faunal analysis, wild hemiones

respectively onagers, wild gazelle, wild sheep

and goat, and wild camel are attested among the

bones. However, the Arisma¯n population relied

largely upon domesticated animals, mainly sheep

and goat and, to a much lesser extent, cattle

31

.

The Arisma¯n ceramic material can closely be

compared with the pottery from Tappe Sialk. In

both sites, it seems, the animals depicted belong

mostly to wild species that figure only rarely in

the faunal record.

The same layer of industrial wasters also

yielded many indicators of metallurgical activities:

Fragments of litharge – a residue of silver pro-

duction –, broken furnaces of the Qabresta¯n type

and moulds were found alongside tools from the

metal production, such as hammer and anvil

stones. These together with pieces of copper

slag, copper prills and occasional copper artifacts

indicate that a workshop for metalworking must

have been in the vicinity; however, it has not

been uncovered yet.

Silver and lead usually occur in one ore to-

gether. Producing silver therefore requires a re-

finement process that is called “cupellation”, in

which silver is separated from lead. Litharge is a

residue of this silver production and appears in

large quantities in Arisman

32

. Fortunately for the

purpose of scientific analysis, lead occurs in dif-

ferent isotope varieties, and the ratio of different

lead isotopes is characteristic for specific ore

sources. An analysis of lead isotope ratios can

therefore provide evidence for the provenience of

the ore. Such an analysis has been carried out on

litharge samples from Arisman and has proven

that the silver ore processed in Arisma¯n quite likely

originated from Nak

¯

lak-Anarak, about 200 km from

Arisma¯n.

Lead isotope analysis can also be carried out

on copper samples, since copper usually con-

tains small amounts of lead as well. The analy-

sis

33

shows that Nak

¯

lak/Anarak may also have

been the source for some of the Arisma¯n copper,

while several copper ore deposits in the vicinity

of Arisma¯n, in the Karkas mountains, could be

excluded as a possible source.

Evidence for late 4

th

millennium BC metallurgy

is more favorable. Located about half a kilometer

north of area B, the walk of a mere 500 m to area

A takes us through almost half a millennium.

Everything began in area A, at least this is true

for the Arisma¯n project. Area A is the location of

one of the three large slag heaps in Arisman,

about 25 m in diameter and more than 1 m in

height.

In area A, a modern irrigation channel cut

through the slag heap. During an international

conference on archaeometry held in Tehran in

1997, a busload of archaeologists went to visit

the site that Davoud Hassanalian, a local teacher

and trained geomorphologist, had reported shortly

before to ICHTO. On this occasion they stopped

at the large slag heap. A radiocarbon sample

was taken from the artificial section and could be

dated to the turn from the 4

th

to the 3

rd

millen-

nium BC.

This was indeed the starting point for the ar-

chaeological project at Arisman. During the first

season in 2000, a trench located right in the middle

of the slag heap was opened that struck upon a

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

28

Ghirshman 1938.

29

Alizadeh 1985.

30

For a full study of the Sialk III pottery production, see R. Bo-

roffka/Parzinger in prep.

31

Pers. comm. Norbert Benecke; Benecke in prep.

32

Pernicka 2004 a; Pernicka 2004 b.

33

Pernicka 2004 a; Pernicka 2004 b.

Early mining and metallurgy on the Western Iranian Plateau

429

copper smelting furnace. The round furnace

stands atop and partly embedded into a mudbrick

platform. In the lower part is a deep, U-shaped

hollow. The upper walls of the kiln are plastered

with mud and strongly slagged. The lower part

does not show slagged walls; probably because

crucibles had been placed there to accommodate

the smelted copper. The front side of the furnace

is destroyed, apparently in order to extract the

smelted metal and the slag accumulated above.

This slag was then removed, resulting in the for-

mation of the enormous slag heap still visible on

the surface. The upper part of the furnace can

most likely be reconstructed as a vaulted struc-

ture. For every new smelting process, the furnace

walls had to be rebuilt. In total, this furnace was

rebuilt 33 times, so that 33 smelting processes

must have taken place in this kiln.

Further investigations on metallurgical activities

at Arisma¯n were aimed at the second large sla-

gheap, area D. Geomagnetic mapping in the cen-

tral part of Arisma¯n 1

34

revealed concentrations

of round spot magnetic anomalies on the eastern

part of the site, stretching north from the large

slagheap in area D. These point to the use of high

temperatures in restricted areas – possibly kilns.

Two trenches were opened in area D: the first

was located immediately in the centre of the slag-

heap in order to find another kiln, but this attempt

was in vain. Besides successive layers of slag,

no feature or structure related with metallurgical

processes was found. The second trench was

therefore placed in an area that had produced

seven magnetic anomalies – kilns?

Subsequent excavations in that area D82 led

to the discovery of large pits that had been dug

into the natural gypsum ground. The walls of

these pits were plastered; the fire inside the pits

must have been intense, as the plaster is fired to

a red color and the gypsum underground is partly

reddish. The fill of the pits contained slag frag-

ments, fragments of moulds and furnaces, a few

eroded pottery fragments of Sialk IV, but no com-

plete artifacts. The function of these pits is not

yet fully understood. At the beginning, we dis-

missed every idea that these pits might have

been related to the smelting of copper. They are

too large to obtain the temperatures necessary to

smelt copper. However, during the last season of

excavation we detected several – smaller – pits

that are, besides their size, very similar to these

large pits in area D and that are clearly linked to

the casting of copper artifacts.

The further processing of the metal smelted in

this industrial area next to the slag heaps took

place in small workshops located within the set-

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

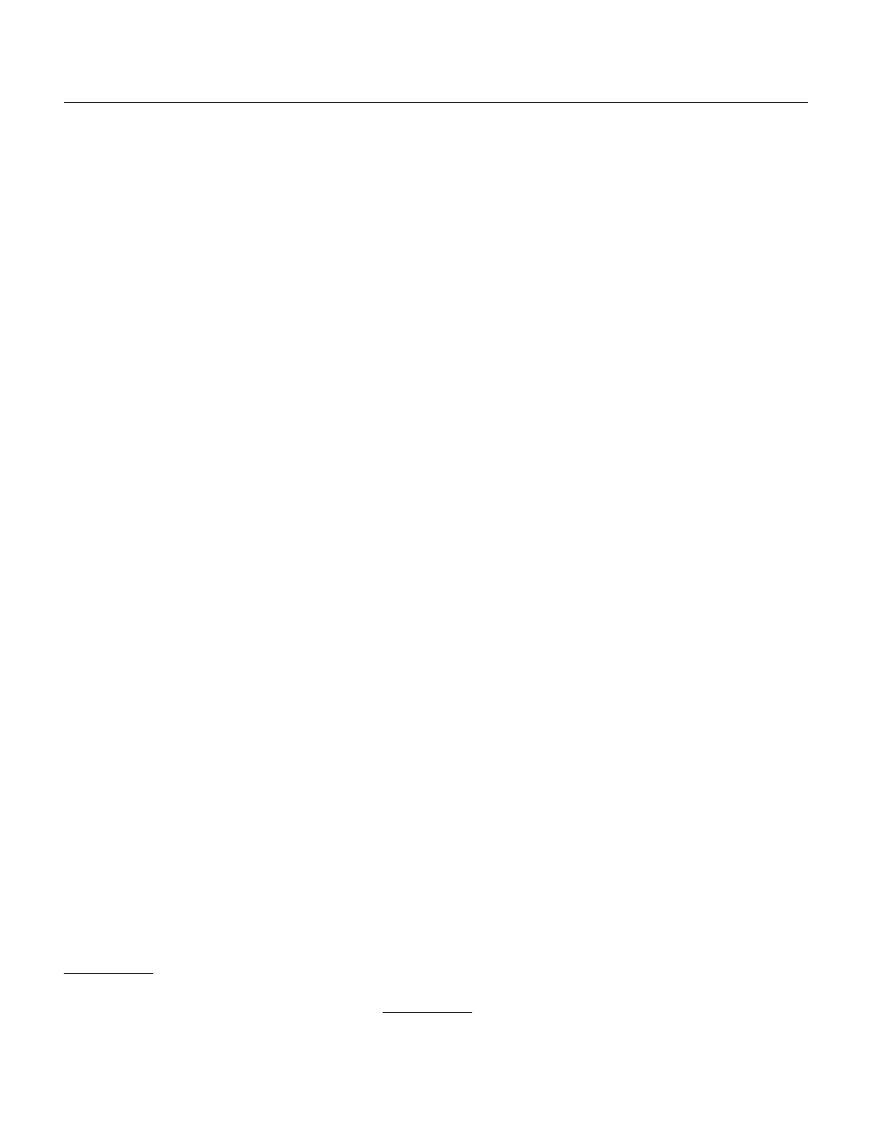

Fig. 4

Arisma¯n. Area C,

settlement of Sialk IV

period (c. 3000 BC).

34

Becker et al. in prep.

Barbara Helwing

430

tlement of the Sialk IV period in area C, which I

shall now introduce in detail. Area C (Fig. 4) con-

sists of large domestic houses with integrated

workshops that were in use over a considerable

stretch of time. The houses extend along both

sides of a street and are arranged in a fairly reg-

ular, urban layout.

At the end of the 2004 season, completed only

three weeks ago, a total of five trenches with a

surface area of almost 400 square meters has

been opened and the sequence of building

phases has been fully deconstructed. In an ex-

emplary way, the archaeological process of de-

construction in square C56 can be followed here:

After removing several fill levels and some floor

layers, installations belonging to the earlier build-

ing phases became visible, such as a vaulted

hearth and a plastered bin next to it. When the

bin was removed, two mould fragments and a

piece of litharge were found behind the wall lin-

ing. Further removal of these installations and of

floor layers allowed us to uncover the lowermost

phase above virgin soil, which yielded further in-

stallations: One is a pit with a plastered and burnt

wall lining filled with charcoal and crucible frag-

ments. Copper residues were also observed. This

pit most probably served as a small furnace for

the smelting and casting of the raw copper that

had been produced in the large furnaces discov-

ered under the slag heaps.

In another room, the lowermost floor held two

plastered pits next to fire platforms, and a piece

of litharge was found next to a platform. Some

other pits that had been dug later contained bur-

ials of children inside large vessels that were cov-

ered with a bowl.

Room fills contain slag, litharge (Fig. 5) and

mould fragments as well as tools for crushing and

grinding ore and slag, and metal artifacts (Fig. 6).

Among the more spectacular finds is a product of

the silver industry: a small silver pendant found

next to the animal style seal. This pendant is

composed of a flat silver sheet onto which small

compartments were added by soldering. These

are filled with stone and metal inlays – marble,

alabaster, hematite and fine gold sheets.

Comparisons for this spectacular silver pendant

are rare. A very simple pendant was found in a bur-

ial at Tappe Sialk

35

, and closely comparable is a

set of silver pendants from Susa

36

, all currently on

display in the German Mining Museum Bochum.

The connection with Susa already points to the

direction of relations that the Arisman site main-

tained during the 4

th

millennium B.C. Apparently,

the materials produced in Arisman were collected

and packed for trade in the workshops within the

site. For the packing, cylinder seals were used to

seal the packages, as is indicated by three cylinder

seals, two of which were found in one single small

room next to a large hearth platform, while the third

was discovered inside a wall of the same building.

Two of these seals are in a local Proto-Elamite

style. The third cylinder seal (Fig. 7) is cut from

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Fig. 5

Arisma¯n. Litharge

from settlement layers

of area C.

Fig. 6

Arisma¯n. Finds related

to metallurgy, Sialk III

and Sialk IV period.

Fig. 7

Arisma¯n. Cylinder

seal, Piedmont

Jamdat Nasr style

(c. 3000 BC).

35

Sto¨llner et al. 2004, 619 Kat. No. 134.

36

Sto¨llner et al. 2004, 656 Kat. No. 245.

Early mining and metallurgy on the Western Iranian Plateau

431

glazed steatite and shows a ladder motif ar-

ranged in a zigzag pattern. The spandrel is filled

with a schematic floral pattern, one leaf once,

and three leaves on the other side. This seal be-

longs to a large stylistic group of seals known as

the “Jemdet Nasr piedmont style” or the “glazed

steatite style”

37

. They are found foremost at sites

in the Za¯gros-Taurus foothills, hence the name,

and are characteristic of the turn of the 4

th

to the

3

rd

millennium BC.

The three seals discovered to date in Arisma¯n

clearly attest the application of seals in the site,

probably for the closing and signing of containers,

and proves that the Arisma¯n population was fa-

miliar with the significance and the codes of seal-

ing. Interestingly, no seal impressions have yet

come to light. In other contemporary sites, for ex-

ample in Sialk period IV

38

or Godin VI/V

39

and

others, the number of seal impressions usually

exceeds by far the number of original seals. One

possible reason for this may be that the sealed

containers were not used within the settlement,

but were sent away. The use of seals in Arisma¯n

can therefore be interpreted as an indicator for

the integration of the site into a larger system of

trading and exchange.

One trigger for the establishment of a long dis-

tance trade network during the 4

th

millennium

BC was the quest for prestigious items that cir-

culated among the elites of the world’s emerging

first states: the Uruk culture in the lowlands of

Mesopotamia and Susiana. The existence of such

a network is beyond doubt. However, current

theories

40

assume that such a network implied at

the same time a cultural dependency, or even a

political dominance of the lowland states over the

highland polities.

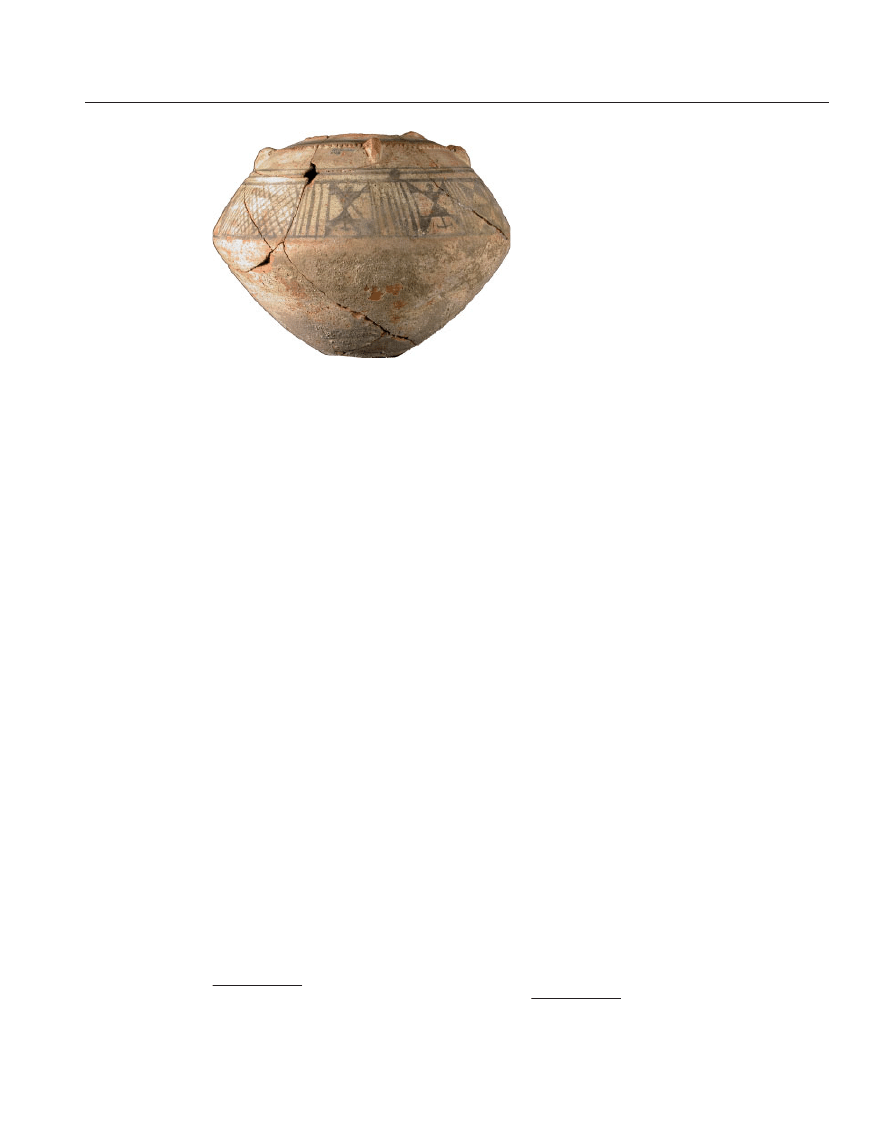

A look at the material culture of daily life, such

as pottery (Fig. 8) can, however, challenge this

theory. The material from Arisma¯n area C shares

only some general forms with the Late Uruk cul-

ture, the alleged exchange partner, but instead

fully matches the assemblages found in the Ker-

ma¯n region and in Fars, where the Proto-Elamite

culture emerged around that time. A region of

shared traditions of pottery manufacture in the

south Iranian highlands is evident here, mirroring

the distribution of the Proto-Elamite culture of

which the Arisma¯n area C occupation was a part.

The origin of the Proto-Elamite culture is so far

not fully understood due to the lack of archaeolo-

gical evidence for the early phases of its exis-

tence

41

. Most popular is the view that the Proto-

Elamite is a secondary state formation in the

windfall of the Mesopotamian Late Uruk culture.

The Arisma¯n material, however, indicates local

pottery traditions and transitional stages between

the mid 4

th

millennium late Sialk III and the Sialk

IV period

42

.

Due to the nature of Arisma¯n as a shifting set-

tlement it is not possible to investigate the transi-

tion between the two periods at that site itself. It

is therefore a fortunate opportunity that Dr. Malek

Shahmirzadi, director of the Sialk Reconsidera-

tion Project, has invited us to investigate these

questions on the very key site for the Central Ira-

nian Plateau – at Tappe Sialk proper. Tappe

Sialk has recently also yielded evidence for cop-

per and silver working

43

, and layers of the Sialk

III and the Sialk IV period exist in immediate stra-

tigraphic superposition. The next season that has

begun just this week will hopefully allow us to

document a sequence of relevant layers on the

southern mound.

Acknowledgements

The Arisman excavations as part of the research

project on Early Mining and Metallurgy on the

Central Iran Plateau have now completed their

fourth season. We gratefully acknowledge the

generous support of the head of ICHTO, Mr. Said

Mohammad Beheshti, and of the directors of the

diverse sections, Dr. Rasool Vatandoust, Dr. Mas-

soud Azarnoush and Mr. Jalil Golshan. Dr. Vatan-

doust together with Prof. Dr. Hermann Parzinger

act as directors of the research project. Excava-

tions at Arisma¯n were directed by Nasir Chegini

and Hamid Fahimi for ICHTO, and by Hermann

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Fig. 8

Arisma¯n. Nose-lug jar,

Sialk III period

(c. 3000 BC).

37

Pittman 1994.

38

Ghirshman 1938.

39

Weiss/Young 1975.

40

Algaze 1993.

41

Helwing 2004.

42

For a detailed discussion of the issue, Helwing 2005.

43

Pernicka 2004 b; Nezafati/Pernicka 2006 (1384).

Barbara Helwing

432

Parzinger and myself for the German Archaeolo-

gical Institute (DAI). The success of the project is

based upon the fruitful and trusting cooperation

of all members of the Iranian and the German

teams. We are greatly indebted to every single

one of them, who made working there such an

exciting and pleasant experience, and I wish to

express my sincere thanks to all.

Bibliography

Adams 1981

R. M. Adams, Heartland of cities: surveys of ancient

settlement and land use on the central floodplain of

the Euphrates (Chicago 1981).

Algaze 1993

G. Algaze, The Uruk World System. The dynamics of

expansion of early Mesopotamian civilization (Chi-

cago 1993).

Alizadeh 1985

A. Alizadeh, A protoliterate pottery kiln from Choga

Mish. Iran 23, 1985, 39–50.

Bazin/Hu¨bner 1969

D. Bazin/H. Hu¨bner, Copper deposits in Iran. Report

13 (Tehran 1969).

H. Becker/Fassbinder/Schlosser in prep.

H. Becker/J. Fassbinder/M. Schlosser, Magnetic pro-

spections in Arisma¯n. In: Nasir Norouzadeh Chegini/

Barbara Helwing/Hermann Parzinger/Thomas Sto¨llner/

Morteza Momenzadeh/Abdulrasool Vatandoust (Eds.),

Early mining and metallurgy on the Central Iranian

Plateau. Report on the first five years of research of

the Joint Iranian-German Research Project, Archa¨olo-

gie in Iran und Turan (Mainz am Rhein in prep.)

Benecke in prep.

N. Benecke, Faunal remains from Arisma¯n. In: Nasir

Norouzadeh Chegini/Barbara Helwing/Hermann Par-

zinger/Thomas Sto¨llner/Morteza Momenzadeh/Abdul-

rasool Vatandoust (Eds.), Early mining and metallurgy

on the Central Iranian Plateau. Report on the first five

years of research of the Joint Iranian-German Re-

search Project, Archa¨ologie in Iran und Turan (Mainz

am Rhein in prep.)

Berthoud et al. 1976

T. Berthoud/R. Besenval/S. Cleuziou/J. Francaix/J. Lis-

zak-Hours, Les anciennes mines de cuivre en Iran.

Recherche cooperative sur programme 442. Unite´ de

recherche arche´ologique 7 (Paris 1976).

N. Boroffka/J. Becker 2004

N. Boroffka/J. Becker, To¨pfero¨fen in Arisman. In: Tho-

mas Sto¨llner/Rainer Slotta/Abdulrasool Vatandoust

(Eds.), Persiens antike Pracht (Bochum 2004) 218–

221.

R. Boroffka/Parzinger in prep.

R. Boroffka/H. Parzinger, Pottery of the Sialk III peri-

od. In: Nasir Norouzadeh Chegini/Barbara Helwing/

Hermann Parzinger/Thomas Sto¨llner/Morteza Momen-

zadeh/Abdulrasool Vatandoust (Eds.), Early mining

and metallurgy on the Central Iranian Plateau. Report

on the first five years of research of the Joint Iranian-

German Research Project, Archa¨ologie in Iran und

Turan (Mainz am Rhein in prep.)

Chegini et al. 2004

N. N. Chegini/B. Helwing/H. Parzinger/A. Vatandoust,

Eine pra¨historische Industriesiedlung auf dem irani-

schen Plateau-Forschungen in Arisman. In: Thomas

Sto¨llner/Rainer Slotta/Abdulrasool Vatandoust (Eds.),

Persiens antike Pracht (Bochum 2004) 210–216.

Chegini et al. 2000

N. N. Chegini/M. Momenzadeh/H. Parzinger/E. Per-

nicka/T. Sto¨llner/R. Vatandoust/G. Weisgerber, Preli-

minary Report on archaeometallurgical investigations

around the prehistoric site of Arisman near Kashan,

western Central Iran. Archa¨ologische Mitteilungen

aus Iran und Turan 32, 2000, 281–318.

Childe 1944

V. G. Childe, Archaeological ages as technological

stages. The Journal of the Royal Anthropological In-

stitute of Great Britain and Ireland 74, 1944, 1–2, 7–

24 and pl. 1–2.

Childe 1948 (1936)

V. G. Childe, Man makes himself. The Thinker’s Li-

brary 87 (London 1948 (1936)).

Ghirshman 1938

R. Ghirshman, Fouilles de Sialk, pre`s de Kashan

1933, 1934, 1937 (I) (Paris 1938).

A. Hauptmann 2000

A. Hauptmann, Zur fru¨hen Metallurgie des Kupfers in

Fenan/Jordanien. Der Anschnitt Suppl. 11 (Bochum

2000).

H. Hauptmann/Pernicka (Eds.) 2004

H. Hauptmann/E. Pernicka (Eds.), Die Metallindustrie

in Mesopotamien bis zum Zweiten Jahrtausend v. Chr.

Orient-Archa¨ologie 3 (Rahden 2004).

Helwing 2004

B. Helwing, Tracking the Proto-Elamite on the Central

Iranian Plateau. In: Sadegh Malek Shahmirzadi (Ed.),

The potters of Sialk. Sialk Reconsideration Project,

Report 3 (Tehran 2004) 45–58.

Helwing 2005

B. Helwing, Long distance relations of the Iranian

highland sites during the late Chalcolithic period: New

evidence from the Joint Iranian-German excavations at

Arisman. In: Ute Franke-Vogt/Hans-Joachim Weiss-

haar (Eds.), South Asian Archaeology 2003. Pro-

ceedings of the seventeenth International Conference

of the European Association of South Asian Archae-

ologists (7–11 July 2003, Bonn), Forschungen zur

Archa¨ologie aussereuropa¨ischer Kulturen (Aachen

2005) 171–178.

Holzer/Momenzadeh 1971

H. F. Holzer/M. Momenzadeh, Ancient coppermines in

the Veshnoveh area, Kuhestan-e Qom, West-Central

Iran. Archaeologica Austriaca 49, 1971, 1–22.

Kramer 1967

S. N. Kramer, Cradle of civilization. Great ages of man:

a history of the world’s cultures (New York 1967).

Majidzadeh 1979

Y. Majidzadeh, An early prehistoric coppersmith

workshop at Tepe Ghabristan. In: Akten des VII. In-

ternationalen Kongresses fu¨r Iranische Kunst und

Archa¨ologie, Munich, 1976, Archa¨ologische Mitteilun-

gen aus Iran, Suppl. 6 (Berlin 1979) 82–92.

Malek Shahmirzadi (Ed.) 2002

S. Malek Shahmirzadi (Ed.), The ziggurat of Sialk.

Sialk Reconsideration Project, Report 1 (Tehran 2002).

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Early mining and metallurgy on the Western Iranian Plateau

433

Malek Shahmirzadi (Ed.) 2003

S. Malek Shahmirzadi (Ed.), The silversmiths of Sialk.

Sialk Reconsideration Project, Report 2 (Tehran

2003).

Malek Shahmirzadi (Ed.) 2004

S. Malek Shahmirzadi (Ed.), The potters of Sialk.

Sialk Reconsideration Project, Report 3 (Tehran

2004).

Momenzadeh 2004

M. Momenzadeh, Metallische Bodenscha¨tze in Iran in

antiker Zeit. Ein kurzer berblick. In: Thomas Sto¨llner/

Rainer Slotta/Abdulrasool Vatandoust (Eds.), Persiens

antike Pracht, (Bochum 2004) 8–21.

Negahban 1977

E. O. Negahban, Preliminary report of Qazvin expedi-

tion: Excavation of Zaghe, Qabristan, Sagzabad

(1971–72). Marlik 2, 1977, 26–44.

Nezafati/Pernicka 2006 (1384)

N. Nezafati/E. Pernicka, The smelters of Sialk.

Outcomes of the first stage of archaeometallurgical

researches at Tappeh Sialk. In: Sadegh Malek

Shahmirzadi (Ed.), The fishermen of Sialk. Sialk Re-

consideration Project, Report 4, Archaeological Re-

port Monograph Series 7 (Tehran 2006 (1384)) 79–

102.

Pernicka 2004

E. Pernicka, Kupfer und Silber in Arisman und Tap-

peh Sialk und die fru¨he Metallurgie in Iran. In: Tho-

mas Sto¨llner/Rainer Slotta/Abdulrasool Vatandoust

(Eds.), Persiens antike Pracht (Bochum 2004) 232–

239.

Pernicka 2004 b

E. Pernicka, Silver production by cupellation in the

fourth millennium BC at Tepe Sialk. In: Sadegh Malek

Shahmirzadi (Ed.), The potters of Sialk. Sialk Recon-

sideration Project, Report 3 (Tehran 2004) 69–72.

Pigott 1989

V. C. Pigott, Archaeometallurgical investigations at

Bronze Age Tappeh Hesar. In: R. H. Dyson, Jr./S. M.

Howard (Eds.), Tappeh Hesar: Reports of the Restudy

Project, 1976, Monografie di Mesopotamia II (Firenze

1989) 25–33.

Pittman 1994

H. Pittman, The Glazed Steatite Glyptic Style: The

Structure and Function of an Image System in the

Administration of Protoliterate Mesopotamia. Berliner

Beitra¨ge zum Vorderen Orient 16 (Berlin 1994).

Smith 1968

C. S. Smith, Metallographic study of early artifacts

made from native copper. In: Actes du XIe Congre`s

International d’Histoire des Sciences, Warsaw, 1965

(Warsaw 1968) 237–243.

Smith 1969

C. S. Smith, Appendix 2: Analysis of the copper bead

from Ali Kosh. In: Frank Hole/Kent V. Flannery/James

A. Neely (Eds.), Prehistory and human ecology of the

Deh Luran Plain: An early village sequence from Khu-

zistan, Iran. Memoirs of the Museum of Anthropology,

University of Michigan 1 (Ann Arbor 1969) 427–428.

Smith et al. 1967

C. S. Smith/T. A. Wertime/R. Pleiner, Preliminary re-

ports of the metallurgical project. In: J. R. Caldwell

(Ed.), Investigations at Tal-i-Iblis. Illinois State Museum

Preliminary Reports 9 (Springfield 1967) 318–326.

Stech 1999

T. Stech 1999, Aspects of Early Metallurgy in Meso-

potamia and Anatolia. In: V. C. Pigott (Ed.), The Ar-

chaeometallurgy of the Asian Old Wolrd. University

Museum Monograph 89, University Museum Sympo-

sium Series Vol. 7, MASCA Research Papers in

Science and Archaeology 16 (Philadelphia) 59–71.

Sto¨llner et al. (Eds.) 2004

T. Sto¨llner/R. Slotta/A. Vatandoust (Eds.), Persiens

antike Pracht (Bochum 2004).

Tallon 1987

F. Tallon, Me´tallurgie Susienne I. De la fondation de

Suse au XVIIIe avant J.-C. Notes et Documents des

Muse´es de France 15 (Paris 1987).

Thomsen 1837

C. J. Thomsen, Leitfaden zur nordischen Alterthums-

kunde (bersetzung von: Ledetraad til nordisk Old-

kyndighed, Kopenhagen 1836) (Kopenhagen 1837).

Wagner/ztunalı 2000

G. A. Wagner/. ztunalı, Prehistoric copper sources

in Turkey. In: nsal Yalcın (Ed.), Anatolian Metal I,

Der Anschnitt suppl. 13 (Bochum 2000) 31–68.

Weisgerber 1980

G. Weisgerber und Kupfer in Oman. Der Anschnitt

32, 1980, 62–110.

Weisgerber 1981

G. Weisgerber, Mehr als Kupfer in Oman. Der An-

schnitt 33, 1981, 174–263.

Weisgerber/A. Hauptmann 1988

G. Weisgerber/A. Hauptmann, Early copper mining

and smelting in Palestine. In: Robert Maddin (Ed.),

The beginning of the use of metals and alloys (Cam-

bridge 1988) 52–62.

Weiss/Young 1975

H. Weiss/T. C. Young, The Merchants of Susa: Godin

V and Plateau-Lowland Relations in the Late Fourth

Millennium B.C. Iran 13, 1975, 1–18.

Wertime 1967

T. A. Wertime, A metallurgical expedition through the

Persian Desert. In: J. R. Caldwell (Ed.), Investigations

at Tal-i-Iblis. Illinois State Museum Reports 9 (Spring-

field, Illinois 1967) 327–339.

Wertime 1968

T. A. Wertime, A metallurgical expedition through the

Persian Desert. Science 159, 1968, 3818, 927–935.

Yener et al. 1989

K. A. Yener/H. zbal/E. Kaptan/A. N. Pehlivan/M.

Goodway, Kestel: An Early Bronze Age source of tin

ore in the Taurus mountains. Science 244, 1989,

200–203.

Yener/Vandiver 1993

K. A. Yener/P. B. Vandiver, Tin processing at Go¨l-

tepe, an Early Bronze Age site in Anatolia. American

Journal of Archaeology 97, 1993, 207–238.

2062395

AMIT

Band 37/2005

Trennprogr.: Englisch

u:/p_1/ai/12ai/_Satzdaten/034/12ai034d.3d

Stand vom: 19.3.2007

Satzprogramm:

3B2

insgesamt 12 Seiten

Bearb.: Storch

Barbara Helwing

434

Wyszukiwarka

Podobne podstrony:

The Great?pression Summary and?fects on the People

Lord of the Flies & All Quiet on the Western Front Author'

HUME AND?SCARTES ON THE THEORY OF IDEAS

All Quiet on the Western Front Very Extensive Book Analysi

Hamao And Hasbrouck Securities Trading In The Absence Of Dealers Trades, And Quotes On The Tokyo St

Leibniz And Cantor On The Actual Infinite(1)

Text which I chose is strongly connected with the economy and conditions on the market

Contagion and Repetition On the Viral Logic of Network Culture

How to set alarm to save picture and video on the SD card

AMC and GM on the medical certification of pilots and medical fitness of cabin crew

zrodla Crusade and Conversion on the Baltic

Attitude Adjustment Trojans and Malware on the Internet

Thoughts and Reflections on the Future o

Influences of Cultural Differences between the Chinese and the Western on Translation

MARSHALL, Louise H National Myth and Imperial Fantasy Representations of Britishness on the Early E

Early Variscan magmatism in the Western Carpathians

więcej podobnych podstron