MATERIALS

CHARACTERIZATION

ELSEVIER

Materials Characterization 57 (2006) 127-135

Effect of heat treatment on microstructure and mechanical properties of cold rolled C-Mn-Si TRIP-aided steel

Ashok Kumar Srivastava a'*, G. Jha b, N. Gope b, S.B. Singh a

a Department of Metallurgical and Materials Engineering, Indian Institute of Technology, Kharagpur, India-721302 b Research and Development, Tata Steel Limited, Jamshedpur, India-831001

Received 18 November 2005; accepted 11 January 2006

Abstract

In the present study, a 0.27C-1.60Mn-2.0Siwt.% TRIP-aided cold-rolled steel sheet was fabricated and optimal heat-treatment conditions (intercritical annealing "IA" and isothermal bainite treatment "IBT") were investigated to maximize the volume fraction and stability of retained austenite. The effects of temperature and time for IA and IBT were studied via optical microscopy, SEM, TEM and XRD. Its tensile properties and formability were also evaluated. Two-stage heat-treatment carried out in a salt-bath furnace revealed that the volume fraction of retained austenite (RA) increased with increasing intercritical annealing time for a particular set of IA temperature, IBT temperature and IBT holding time. When the volume fraction of the retained austenite was 9% or higher, the stability of RA in terms of carbon concentration was same, and better formability was obtained. It was also observed that high tensile strength of 652 MPa, tensile elongation of 31% or above, and n-value 0.2 could be successfully produced in this cold-rolled steel sheet at IA temperature of 800 °C, holding for 5 min, and IBT of 400 °C for 3 min holding time. © 2006 Elsevier Inc. All rights reserved.

Keywords: TRIP steel; Microstructure; Mechanical properties; Retained austenite

1. Introduction

The reduction in the weight of passenger car is becoming the driving force in order to improve the fuel efficiency and superior environmental control by using high strength thinner gauge steel sheet. In general, with standard high-strength steel, there is a linearly decreasing correlation, i.e., when the strength increases, the elongation decreases. Off late, there has been a lot of research in the area of relatively steel grades, like TRIP (transformation induced plasticity)-aided cold-rolled

* Corresponding author. Tel.: +91 3222 281706; fax: +91 3222 25503.

E-mail address: aksrivastava@metal.iitkgp.ernet.in (A.K. Srivastava).

steel which shows higher strength without much of a loss in ductility. The microstructure of TRIP-aided steels consists of ferrite, bainite and metastable retained austenite obtained by tradicious heat treatment of cold-rolled steel. This steel offers large dynamic energy absorption and thus leads to improved crash worthiness for better passenger safety. These excellent mechanical properties mainly arise from strain-induced transformation of retained austenite to martensite, accompanied by a volume expansion resulting in plastic deformation and the work hardening of surrounding ferritic phases. This strain-induced transformation gives rise to high uniform elongation by delaying the onset of necking.

The microstructure of TRIP-aided steels is achieved by carrying out a two-stage heat treatment after cold rolling as shown in Fig. 1 [1,2]. The first stage of heat

1044-5803/$ - see front matter © 2006 Elsevier Inc. All rights reserved. doi:10.1016/j.matchar.2006.01.010

128

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

Time

Fig. 1. Schematic representation of the thermal cycle used to obtain the typical TRIP microstructure.

treatment is carried out at slightly higher temperature in the α+γ two-phase region, leading to a microstructure of about 50% austenite and 50% ferrite. A fast cooling rate after annealing is employed to avoid any major ferrite formation and the final transformation is carried out isothermally in the bainite region (second stage heat treatment). During bainite formation, the carbon diffuses into the austenite islands. The enrichment of carbon in the austenite increases its thermal stability and, consequently, the austenite can be retained upon cooling to the room temperature [3-7].

Studies on currently available classical C-Mn-Si TRIP-aided cold-rolled steel sheets reveal that quite a large number of researchers have carried their work on steels containing carbon in the range of 0.10—0.20wt.% for better weldability. However, in order to get a high volume fraction of metastable retained austenite during intercritical annealing, a carbon content in the range of 0.25-0.30wt.% was selected for the present study. The purpose of the study was to establish an appropriate IA and IBT conditions. Subsequently, the effect of intercritical annealing time on the nature of retained austenite and mechanical properties was evaluated.

2. Experimental procedure

The chemical composition of the TRIP steels used in this study is given in Table 1. The CMnSi TRIP-aided

Table 1

Chemical composition (wt.%) of experimental heat

Trip steel |

C |

Mn |

Si |

P |

Al |

S |

Nb |

C-Mn-Si |

0.27 |

1.60 |

0.0150 |

0.021 |

0.021 |

0.015 |

0.005 |

Table 2

Heat treatment detail of samples

Sample |

IA |

IA time |

IBT |

IBT time |

code |

temperature |

(min) |

temperature |

(min) |

A |

800 |

10 |

400 |

3 |

C |

800 |

5 |

400 |

3 |

B |

800 |

10 |

400 |

5 |

D |

800 |

5 |

400 |

5 |

was prepared as a 50 kg ingot in an air induction furnace. The cast ingot was forged into a 300 × 150 × 50mm block. Small blocks of 120 × 120 × 50 mm were cut from forged stock. These 50mm thick blocks were soaked at 1175 °C for 1 h, and hot rolled to a thickness of 3.2mm in eight passes. Hot rolled plates were annealed at 900 °C for 1h to reduce the hardness for easier cold rolling. The hot-rolled air annealed steel plates were pickled in a 25vol.% HCl solution and subsequently cold rolled to achieve a final thickness of 1 mm.

Fig. 2. Pseudo-binary phase diagram along with the T0 curve for the steel under investigation.

The equilibrium austenite start (Ae1) and finish (Ae3) and the theoretical limit for bainitic transformation (T0) temperatures were found from the calculated phase diagrams. The intercritical annealing and isothermal bainitic transformation temperatures were selected based on these calculations. The phase transformation behaviour was also studied by means of dilatometry. Solid cylindrical samples with a diameter of 3 mm and a length of 5 mm, cut from hot-rolled sheet, having an initial pearlite-ferrite microstructure, were heated to 1100 °C at 1 °C s− 1 under vacuum. An extensometer was used to measure dilatation across the sample diameter. Comparisons were made

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

Fig. 3. Dilatation vs temperature for determination of Ac1 and Ac3 (heating rate 1 °C s ') of CMnSi cold-rolled TRIP steels.

between Thermo-calc results and the dilatometry experiments for CMnSi cold-rolled specimens for different heat treatment conditions. Ac1, Ac3 andMS temperatures were also determined by dilatometry curves.

In order to obtain a TRIP-aided steel, a two-step heat treatment was used. The cold-rolled CMnSi steel samples were heat treated in two separate salt baths kept at two different temperatures to simulate inter-critical annealing (IA) and isothermal bainitic transformation (IBT), respectively. The salt solution consisted a mixture of BaCl2 (80%) and NaCl (20%). The isothermal bainite treatment was carried out at a temperature 10°C higher than MS (390 °C), followed by air cooling. The four sets of heat-treated samples are shown in Table 2. The heat treated samples were subjected to measure the volume fraction of retained austenite and its carbon content.

Cold-rolled heat treated samples were prepared for microstructural studies with the LePera color-tint etching technique [10]. The room temperature tensile properties (yield strength for 0.2% offset strain, ultimate tensile strength and elongation) of heat treated samples were evaluated on a gauge length of 50 mm with 6.4mm nominal width. Tensile tests were carried out in an INSTRON universal testing machine using a load range of 5000 kgf. The crosshead speed was maintained at 5mm/min. The fractured surfaces of tensile tested specimens were examined using scanning electron microscopy (SEM).

Thin slices 0.05mm-thick slices were prepared from the heat treated specimens at an extremely low speed using an ISOMET low speed saw followed by electro-polishing using an electrolyte of 10% HCl + 90%

129

glacial acetic acid. The foils were examined in a JEOL 200 CX transmission electron microscope (TEM) operating at 160 or 200 kV for identifying the retained austenite. To evaluate the stamping formability of the cold-rolled sheet as a function of heat-treatment condition, the forming limit curve (FLC) was calculated by commercial FE based code-PAM stamp 2G software.

3. Results

3.1. Determination ofIA and IBT temperatures

The pseudo-binary equilibrium phase diagram and the allotropic phase boundary (T0 line) at which the austenite and ferrite of identical composition have equal Gibbs energy were calculated with the help of thermodynamic software Thermo-calc™, using TCFE3 database for the CMnSi steel under investigation. The pseudo-binary phase diagram for the steel is given in Fig. 2. The austenite start (Ae1) and the austenite finish (Ae3) temperatures are 823 and 705 °C, respectively. The presence of high Mn and Si widens the intercritical (α + γ) loop and the coexistence of alpha and alloy carbide is evident at the lower intercritical temperatures.

Samples were heated to 1100 °C at a rate of 1°Cs − to determine Ac1 and Ac3 and found to be 734 and 855 °C, respectively, as illustrated in Fig. 3. And the MS temperature was found to be 390 °C. The experimental results for the TRIP steel compositions are summarised in Table 3. The thermal dilatation was determined for both the ferrite and the austenite and the transformed fraction was calculated. The measured transformed fraction is compared with the calculation of the transformed fraction by means of the Thermo-calc software in Fig. 4. It may be seen from the figure that a good match exists between the calculated and experimental values for the steel composition.

The volume fraction of austenite transformed during the IA can be calculated from the relative change in the length of the sample by comparing for full transformation to austenite by the lever rule. Higher annealing temperatures resulted in a large sample contraction leading to enhanced transformation of ferrite-pearlite in to austenite.

Table 3 Measured Ac1, |

Ac3 |

and MS values |

for CMnSi TRIP steel |

|

TRIP steel |

|

Ac1 (°C) |

Ac3 (°C) |

MS (°C) |

C-Mn-Si |

|

734 |

855 |

390 |

130

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

Fig. 4. Comparison of transformation temperatures of dilatometry with Thermo-calc calculation of CMnSi cold-rolled TRIP steels.

3.2. Microstructure

10 Hi"

Fig. 5. Microstructure of cold-rolled TRIP steel samples at 500×.

Fig. 5 is the optical micrograph of sample in cold-rolled condition. Figs. 6a and b are the optical micrographs of the salt bath heat-treated samples A and C, respectively. The areas displayed as faded white or grey are ferrite, the bright white ones are retained austenite, straws are martensite and the bluish-blacks are bainite. Retained austenites are homogeneously distributed throughout the microstructure, and are connected to adjacent ferrites or bainites. The volume fraction of austenite is about 12% in sample A and about 9% in sample C. This suggests that the amount of austenite increases with an increase in intercritical annealing time. Fig. 7 shows the TEM micrograph of heat-treated sample A. It may be seen from bright field images that a bainite part is

Fig. 6. Microstructure of CMnSi cold-rolled salt baths heat-treated (a) sample A and (b) sample C.

composed of a set of parallel ferrite laths. This appears to consist of an adjacent pile up of laths. It is clear that a large amount of residual austenite (the illuminated phases in dark field condition) is retained between the laths of bainitic ferrite. Selective area diffraction pattern shown in Fig. 7d clearly confirms the presence of retained austenite.

3.3. Measurement of retained austenite (RA)

The volume fraction of retained austenite in heat treated samples was determined by X-ray diffraction (XRD) using Mo Kα radiation. Integrated intensity of (211) peak of ferrite and (220) and (311) peaks of austenite were used for this purpose and the volume fraction of retained austenite was calculated using the following equation [8].

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

131

Fig. 7. TEM micrographs of CMnSi cold-rolled heat-treated sample A for (a) and (b) bright field (c) dark field and (d) selected area diffraction.

where I is the average integrated intensity obtained at (220) and (311) peaks, and I is that obtained at (211) peak. For the calculation of the C content of the retained austenite, the lattice parameter a0 was measured from the (220) diffraction peak using the equation a0 (Å) = (3.578+0.033)wt.% C [9].

Fig. 8 shows the measured data of XRD with Mo Kα radiation for heat-treated samples A and C. The results are shown in Table 4. It can be seen from Table 5 that when the IA time is increased from 5 to 10min, the amount of retained austenite increased from 9.98% to 12.68%. The calculated carbon

132

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

Table 4

A C B D

XRD results for salt-baths heat treated samples

Sample |

Heat treatment |

Intensity |

|

|

RA |

code |

details |

α-iron |

γ-iron |

|

|

|

|

(200) (211)(220)(311) |

(220) |

(311) |

|

IA-800°C-10min 102.96 141.72 19.32 10.08 12.68%

IBT-400°C-3min

IA-800°C-5min 145.65 186.76 19.43 9.25 9.98%

IBT-400°C-3min

IA-800°C-10min 99.85 139.28 18.78 9.42 12.41%

IBT-400°C-5min

IA-800°C-5min 139.25 181.96 19.02 9.06 9.75%

IBT-400°C-5min

content in retained austenite was 0.84% in both the samples.

3.4. Mechanical properties

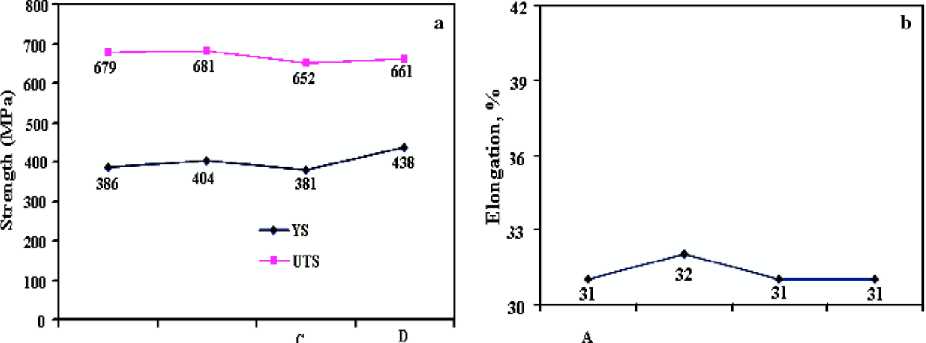

Tensile specimens from the rolling direction were tested, and the results are shown in Table 5. All of the four samples showed tensile elongation of more than 30%, despite the high tensile strengths above 650MPa. The strain-hardening exponent, n, varied with heat-treatment conditions. Samples A and B showed somewhat higher values of 0.224 and 0.213, respectively, compared with 0.199 and 0.168 for samples C and D, respectively. Although the elongation stayed at about the same level for all IA and IBT times, the n-value for samples A and B increased with the higher IA time (10 min). The variation in IBT time did not show any effect on n-value. Fig. 9 shows the influence of heat-treatment conditions on the strength and elongation for different samples.

Comparative analysis of the four specimens in terms of overall tensile properties showed that the specimens A and B had marginally better not really mechanical properties. As TRIP-aided steels combine a high-strength with a high elongation, the product of TS and total elongation is often used to characterize their mechanical properties. The TS×El product of all the

samples under this work falls in the range of 20,000 to 21,000, which is in agreement with the reported data of 20,000 to 24,000 for C-Mn-Si TRIP-aided steel [11]. Fig. 10 represents the fractograph of fractured A and C samples. From these set of micrographs, it can be observed that both samples have same ductile features. It indicated that variations in IA time do not have any significant effect on fracture mode.

3.5. Formability

Fig. 11 shows FLC obtained from commercial finite element based on code-PAM stamp 2G software. In general, the higher the FLC level is, the better is the formability. The FLC0 value, which is the limit plane strain corresponding to the lowest point in a plane strain mode (− 0.1be2b0.2), conveys the level of forming performance [12-14]. Although samples A and B show relatively higher FLC0 of 31.5%, FLC0 of the other two samples are 30.5% and 26%, respectively. The forming limit in the regions where − e2 value is large is similar to the uniform elongation data under uniaxial tension (Table 5). The retained austenite of samples A and C is approximately 12% and 9%, respectively, revealing the better formability of the former. It is worthwhile to mention here that forming limit is strongly influenced by stability of retained austenite also.

4. Discussion

Heat-treatment conditions of intercritical annealing and isothermal bainite treatment are vital for the formation of retained austenite. At a predetermined intercritical annealing temperature, the retained austenite volume fraction increases with an increase in time until the equilibrium volume fraction of γ determined by the Ac3 line is achieved. However, a large fraction of retained austenite is not desirable because the reduced carbon content of retained austenite would make it less stable. At 800°C, (Ac1 +Ac3)/2, the fraction of retained

Table 5

Tensile results of salt-baths heat treated CMnSi cold-rolled samples

Sample code |

Heat treatment details |

TS (MPa) |

UTS (MPa) |

YS/UTS |

EL (%) |

n-value |

UTS×EL(MPa*%) |

A |

IA-800°C-10min |

386 |

679 |

0.57 |

31 |

0.224 |

21,049 |

|

IBT-400°C-3min |

|

|

|

|

|

|

C |

IA-800°C-5min |

381 |

652 |

0.58 |

31 |

0.208 |

20,212 |

|

IBT-400°C-3min |

|

|

|

|

|

|

B |

IA-800°C-10min |

404 |

681 |

0.59 |

32 |

0.213 |

21,792 |

|

IBT-400°C-5min |

|

|

|

|

|

|

D |

IA-800°C-5min |

438 |

661 |

0.66 |

31 |

0.198 |

20,491 |

|

IBT-400°C-5min |

|

|

|

|

|

|

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

133

B

B C

Sample Code

Sample Code

Fig. 9. Variation of (a) strength (YS and UTS) and (b) % elongation with various heat-treated conditions.

austenite formed during the intercritical annealing is approximately 50%. The samples isothermally treated at 400 °C (10 °C higher than MS) for 180 s show the higher retained austenite fraction in specimen A compared to specimen C.

Samples A and B have excellent formability and mechanical properties. This may be attributed to the fact that the two specimens have higher strain-hardening index and elongation than conventional high-formabil-ity cold-rolled steel sheet. Samples C and D do not show good formability despite high elongation. This may be due to a lower percentage of austenite because of shorter holding time at intercritical annealing temperature. During isothermal treatment, the carbon content in retained austenite increases, as the amount of retained austenite is reduced leading to extremely high stability of retained austenite. This retained austenite does not transform to martensite even at high strains leading to poor formability. This indicates that the stability

becomes very high when the carbon solubility in retained austenite goes beyond the critical level due to a decrease in intercritical annealing time.

During plastic deformation, the strain-induced retained austenite relaxes the stress concentration thereby delaying the necking and increasing the elongation [15]. The carbon concentration in finally formed retained austenite is around 0.84% with the base composition of 0.27% C in the cold-rolled steel. This indicates that the stability of retained austenite goes high when the carbon solubility in retained austenite goes beyond adequate level due to appropriate intercritical annealing temperature and higher holding time at that temperature. Based on these findings, the optimal heat treatment conditions were selected, i.e., intercritical annealing at 800 °C at which the volume fraction of ferrite and austenite is 50:50 and then isothermal treatment at 400 °C in order to obtain excellent tensile strength and elongation.

Fig. 10. Sets of fractograph for fractured surfaces of tensile tested specimens (a) sample A and (b) sample C.

134

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

Fig. 11. Forming limit curve obtained from commercial finite element software for the cold-rolled heat treated samples.

With the help of X-ray diffraction, it was possible to show the amount of retained austenite after 180 s holding time of IBT at 400 °C. Carbon was ejected into the austenite resulting in an increase in the volume fraction of retained austenite as evident from the microstructure. As the kinetic of the bainite transformation and the subsequent enrichment of austenite with carbon are slower, a higher IBT time was chosen to get higher volume fraction of retained austenite. However, keeping IBT time and temperature constant with varying time of intercritical annealing time results in 3% higher volume fraction of retained austenite with increase in time from 300to 600s. This high stability of the retained austenite allows the steady strain-induced transformation of austenite without abrupt drop in strain hardenability leading to enhanced formability. Matsumura et al. reported that the effect of retained austenite on formability could be described by initial volume fraction and the stability of retained austenite [16].

During IBT, the laths of bainitic ferrite grow diffusionlessly. In this diffusionless growth process, the excess carbon in supersaturated ferrite is rapidly released to the surrounding austenite leading to carbon enrichment of austenite as evident from TEM and measured value of carbon concentration by X-ray diffraction. TEM study reveals that bainitic ferrite laths have developed side by side. This is the reason of rapid build-up of carbon concentration in austenite domain near the interface at

400 °C IBT. Any interlath austenite was not found for this isothermal bainite transformation temperature.

5. Conclusions

In the present study, a Si-based 0.27 wt.% C cold-rolled steel was heat-treated. Its tensile properties and formability along with the characterization of retained austenite were determined. The main conclusions of the present study are as follows:

Major finding from this study indicates that for a

particular chemistry, intercritical annealing and

isothermal bainite transformation should be opti

mized to have an optimum volume fraction as well as

optimum stability of retained austenite in order to get

high-tensile cold-rolled TRIP-aided steel with better

formability.The volume fraction of retained austenite was 12%

with IA 800°C for 10min and 9% for IA 800°C for

5min, respectively, for similar IBT.The carbon concentration was 0.84% in retained

austenite revealing the higher stability.The presence of retained austenite was revealed

by XRD and also confirmed by optical and TEM

studies.High tensile strength of 600 MPa, elongation of 31%

or above and n-value of 0.2 could be successfully

A.K. Srivastava et al. /Materials Characterization 57 (2006) 127-135

135

produced with this chemistry by optimizing the heat-treatment conditions.

References

[1] Jacques P, Cornet X, Harlet Ph, Ladriere J, Delannay F. Metall

Trans A Phys Metall Mater Sci 1998;29A:2383. [2] Jacques P, Mertens A, Girault E, Ladriere J, Delannay F. Metall

Trans A 1990.

[3] Chen HC, Era H, Shimizu M. Metall Trans 1989;20A:437. [4] Jeong WC, Matlock DK, Krauss G. Mater Sci Eng A Struct

Mater Prop Microstruct Process 1993; 165:9. [5] Matsumura O, Sakuma Y, Takechi H. Trans ISIJ 1992;32:1014. [6] Itami A, Takahashi M, Ushioda K. Proceedings of the

International Symposium on Low-Carbon Steels of the 90',

PA; 1994. p. 245.

[7] Sugimoto K, Usui N, Kobayashi M, Hashimoto S. ISIJ Int

1992;32:1311. [8] De Meyer M, Vanderschueren D, De Blauwe K, De Cooman BC.

"The characterization of retained Austenite in TRIP Steels by X-

Ray Diffraction", 41st MWSP Conf. Proc., ISS; 1999. p. 483-91. [9] Dyson DJ, Holmes B. Iron Steel Ins 1970;208:469. [10] Dey AK, Speer JG, Matlock DK. Adv Mater Process February

2003;161:27. [11] De Meyer M, Vanderschueren D, De Cooman B. Iron Steel Inst

JpnInt 1999;39:819.

[12] Kim YS, Park KC, Kor J. Soc Mech Eng 1993;33:47. [13] Sowerby R, Duncan JL. Int J Mech Sci 1971;13:217. [14] Painter MJ, Pearce R. J Phys D Appl Phys 1974;7:992. [15] Hiwatashi S, Takahashi M, Katayama T, Usuda M. Jpn Soc Tech

Plas 1994;35:1109. [16] Matsumura O, Sakuma Y, Ishii Y, Zhao J. ISIJ Int 1992;32:1110.

Wyszukiwarka

Podobne podstrony:

32 425 436 Ifluence of Vacuum HT on Microstructure and Mechanical Properties of HSS

52 737 754 Relationship Between Microstructure and Mechanical Properts of a 5%Cr Hot Works

Microstructure and mechanical properties of plasma sprayed H

6 63 76 Influence of Surface Heat Treatment on Thermal Fatique Behaviour

Fibrillar Structure and Mechanical Properties of Collagen

53 755 765 Effect of Microstructural Homogenity on Mechanical and Thermal Fatique

53 755 765 Effect of Microstructural Homogenity on Mechanical and Thermal Fatique

71 1021 1029 Effect of Electron Beam Treatment on the Structure and the Properties of Hard

Effect of vacuum microwave drying on selected mechanical and rheological properties of carrot

31 411 423 Effect of EAF and ESR Technologies on the Yield of Alloying Elements

Effects of the Great?pression on the U S and the World

Possible Effects of Strategy Instruction on L1 and L2 Reading

Effect of caffeine on fecundity egg laying capacity development time and longevity in Drosophila

więcej podobnych podstron