Combined osmotic and microwave-vacuum dehydration of apples

and strawberries

q

Ulrich Erle

*

, Helmar Schubert

Institute of Food Process Engineering, Karlsruhe Technical University, 76128 Karlsruhe, Germany

Received 1 June 2000; accepted 1 December 2000

Abstract

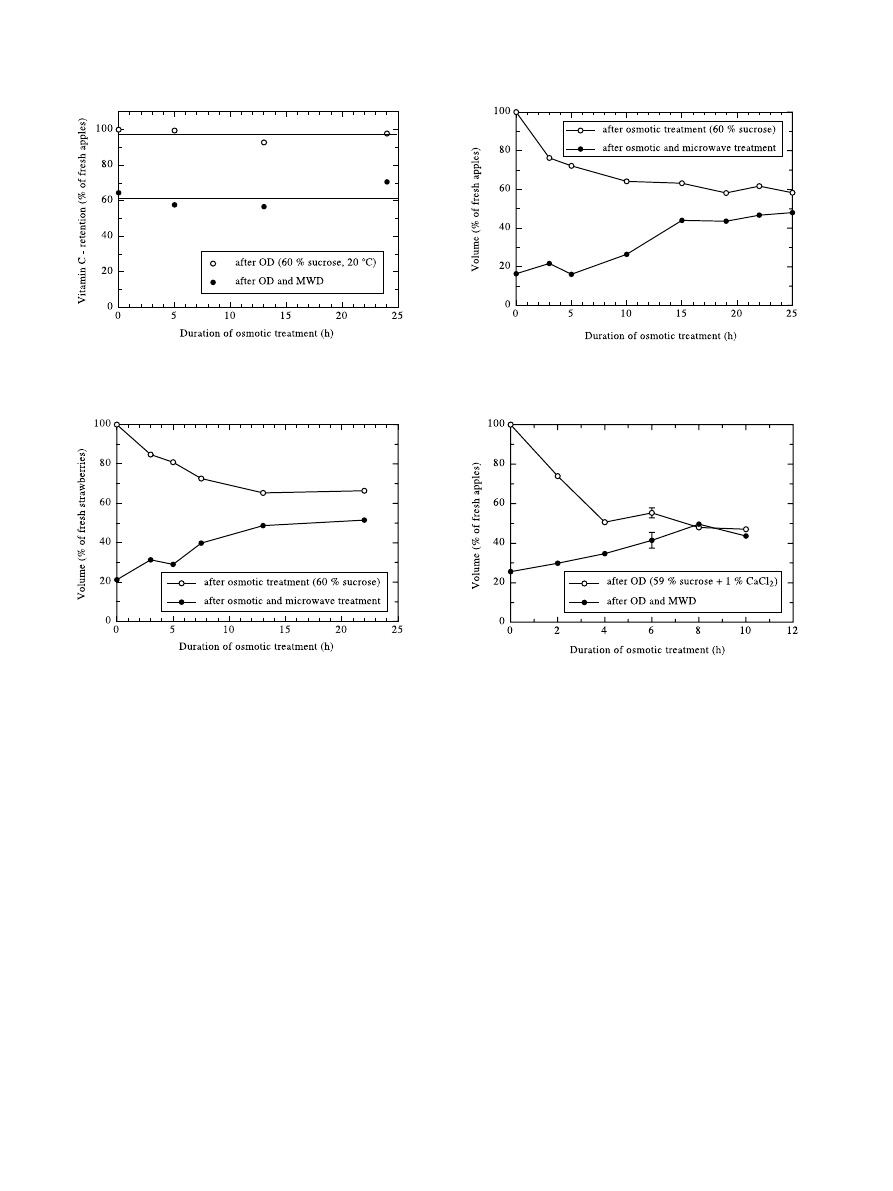

The combination of osmotic pre-treatment ± mainly in sucrose solutions ± and microwave-vacuum dehydration of strawberries

and apples has been studied. Water removal during osmotic treatment is accompanied by solute uptake from the osmotic solution.

The resulting changes in composition bring about better properties of the ®nal product in terms of structure and volume. Compared

to the solely microwave-vacuum dried samples, osmotic pre-treatment improved volume retention from 20% to 50% (strawberries)

and from approximately 20% to 60% (apples) based on the fresh volume. SEM pictures revealed that the cellular structure is also

preserved better, when osmotic pre-treatment is used. Gel formation between pectins, sucrose and in some cases, calcium ions is

believed to be the main cause of structure build-up. Vitamin C retention was around 60% with the microwave procedure applied

here. Ó 2001 Elsevier Science Ltd. All rights reserved.

Keywords: Volume retention; Vitamin retention; Structure; Gel formation; Pectin

1. Introduction

Osmotic dehydration is a very gentle method to re-

move water from plant tissues such as fruits or vegeta-

bles. While more than 50% of the water leaves the tissue

due to lower water activity in the surroundings, some

solutes from the osmotic solution are usually able to

penetrate the plant material despite the obstacles they

encounter in the form of cell walls and especially cell

membranes. These changes in composition can be ex-

ploited in order to create modi®ed properties of the ®nal

product. Unfortunately, the water activity attainable by

osmotic dehydration alone is still rather high. Further

means of water removal are therefore needed to ac-

complish the goal of shelf stability at room temperature.

In this study, microwave-vacuum dehydration has

been used to achieve water activity lower than 0.5. The

products obtained were of high quality concerning taste

and colour. Retention of vitamin C was measured, be-

cause the substance has a high nutritional value and its

absence is an indicator of thermal damage. Volume after

osmotic treatment alone and after combined treatment

was determined in order to demonstrate how the con-

ditions of osmotic treatment in¯uence both the osmotic

process itself and the properties of the ®nal product.

Measurements of the changes in sugar composition

during the osmotic process were taken to see, whether

the system can be treated like one of simple diusion.

2. Theory

The term `osmosis' refers to system of at least two

liquids with dierent solvent activities. These are sepa-

rated by a semipermeable membrane, i.e., a barrier

which lets the solvent pass but not the solutes. The result

is a ¯ow of solvent from the region of high to the region

of low activity.

In the case of fruits and vegetables the solvent is, of

course, water. Typical osmotically active substances in-

clude sugars, alcohols and salt (Barbosa-Canovas &

Vega-Mercado, 1996). Although the achievable molar

fractions are quite low, soluble starch is also an eective

osmotic agent (Isse & Schubert, 1995). In plant materi-

als, the cell membranes provide a ± more or less ±

Journal of Food Engineering 49 (2001) 193±199

www.elsevier.com/locate/jfoodeng

q

The ®rst part of this manuscript including Figs. 1±9 was

originally published in: Fito, P.; Chiralt, A.; Barat, J.M.; Spieû,

W.E.L. (2000). Osmotic Dehydration and Vacuum Impregnation:

Applications of New Technologies to Traditional Food Industries.

Technomic Publishing, Lancaster, USA.

*

Corresponding author. Tel.: +49-721-608-4366; fax: +49-721-

694320.

E-mail addresses: ulrich.erle@lvt.uni-karlsruhe.de, ulrich.erle@

merck. de (U. Erle).

0260-8774/01/$ - see front matter Ó 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 26 0 - 8 7 7 4 ( 0 0 ) 0 0 20 7 - 7

semipermeable barrier. In fact, some part of the solutes

is usually able to penetrate the tissue. The material may

also lose a portion of its own solutes (vitamins, volatiles,

minerals. . .). Fig. 1 gives an overview of these transport

phenomena.

Owing to the low boiling point at low pressures,

vacuum application oers the bene®ts of dehydration at

temperatures, where the thermal damage is practically

non-existent. At 5 kPa, the pressure applied in this

study, the boiling point of pure water is 32.9°C. As long

as there is enough water in the tissue, this boiling point

can only be exceeded minimally due to dissolved sub-

stances. In the ®nal stages of microwave drying, tem-

perature may reach 80°C, but thermal damage in this

period is still relatively low, because the heat sensitivity

decreases with decreasing water content. The use of

microwaves overcomes the usual problem of poor heat

transfer in vacuum drying. In microwave-vacuum dry-

ing, heat is not transferred to but generated in the tissue.

This allows for energy transfer rates much higher than in

conventional drying operations, especially in the falling

rate period (Roussy & Pearce, 1995). The absorption of

microwaves by a sample depends on its dielectric

properties, which are positively correlated with the wa-

ter content. That is why, to a certain extent, the distri-

bution of power in microwave drying is self controlled:

those areas which received more power than others dry

quicker and will therefore absorb less power from then

on. However, when the power level is set too high,

overheating and burning of dry areas, a so-called

`thermal runaway', may occur (Buer, 1993).

The application of an osmotic treatment prior to

microwave-vacuum drying combines the advantages of

both unit operations in a unique way: since no phase

transition takes place in osmotic dehydration, energy

consumption is especially low, even if the diluted solu-

tion needs to be reconcentrated by evaporation. Mi-

crowaves require electricity, a relatively expensive form

of energy, but they are only employed in the ®nal stages

of drying, where they can be used more eciently than

hot air (Gunasekaran, 1999).

Structure and volume of the product may suer

during microwave-vacuum dehydration. Osmotic pretr-

eaments provide a tool for incorporating sucrose or

other solutes in the food, which may already contain

pectins. These are known to form gels with sucrose and

calcium ions (Pilnik, 1980; Glenn & Poovaiah, 1990).

The resulting improvements of structure and volume are

the main subject of this study. Another bene®cial eect

is that the addition of sugars in general means that less

water needs to be removed for shelf stability. When ions

are used in the osmotic solution, they will normally enter

the tissue, thereby increasing its dielectric loss factor,

which makes microwave drying more ecient.

3. Material and methods

3.1. Osmotic treatment of apples

Apples (`Golden Delicious') were cored, peeled and

cut in 12slices, which were treated osmotically. Ap-

proximately 400 g of apple slices (12±18 cm

3

) were put

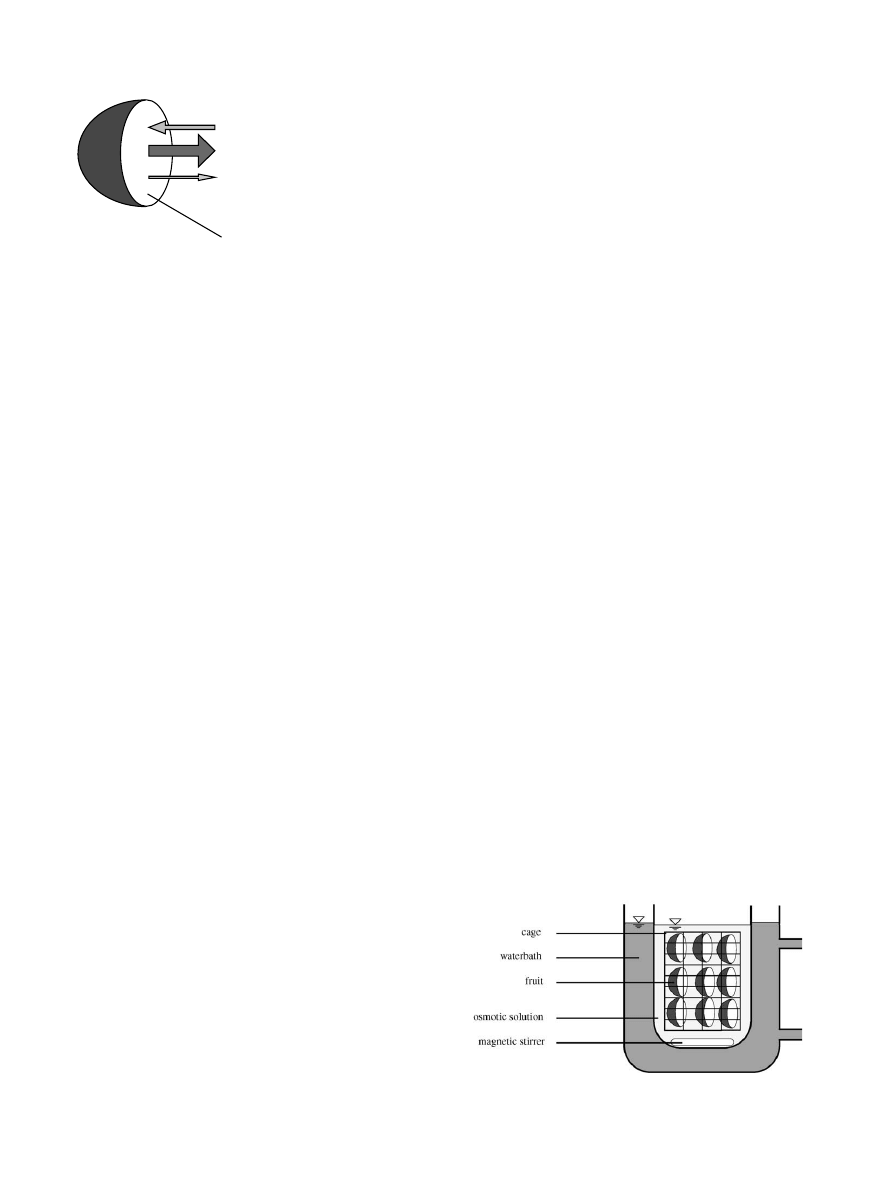

into a stirred 60% (w/w) sucrose solution (see Fig. 2).

When calcium chloride was added to the solution, su-

crose concentration was decreased accordingly, so as to

keep the water concentration constant at 40% (w/w).

The ratio of apples to solution was 1:9. Osmotic treat-

ment was carried out for durations ranging from 2±25 h.

Temperatures were between 20°C and 70°C. Concen-

tration of calcium chloride was varied between 0% and

6%. After treatment, samples were dipped into water ®ve

times, blotted in kitchen paper, weighed and used for

measurements or microwave-vacuum drying.

3.2. Osmotic treatment of strawberries (for sugar and

vitamin C measurements)

Measurements of sugar concentration and vitamin C

tend to be quite scattered when they are conducted with

dierent batches or with the same batch, but at dierent

ripeness of the fruits. Hence, a bigger vessel for osmotic

dehydration has been used in these experiments. It is

capable of holding more than 20 samples of 100 g from

one batch resulting in much reduced scattering of the

data compared to earlier measurements, in which a new

water

dissolved substances:

sucrose

calcium

dissolved substances:

sugars

minerals

colour

volatiles

piece of fruit

semipermeable membrane(s)

Fig. 1. Mass transfer during osmotic treatment.

Fig. 2. Set-up for osmotic treatment of 400 g of fruit.

194

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

batch of fruit had to be used for each duration of os-

motic treatment. One objective here was to detect pos-

sible enzymic activity due to osmotic treatment in

sucrose solution, which would cause changes in the

sugar composition of the strawberries. In addition, the

sucrose uptake in time had to be documented.

Twenty-two samples of 100 1 g of medium sized

strawberry halves (4±8 cm

3

) were put in nets and dried in

a stirred 60% sucrose solution (20 kg) at 20°C. After

treatment, samples were dipped into water three times,

blotted in kitchen paper, weighed and frozen for later

analysis or microwave-vacuum dried for vitamin C

measurements of the ®nal product. Three more samples

were just dipped in a 60% sucrose solution and then

treated like the other samples to serve as reference.

3.3. Osmotic treatment of strawberries (for volume

measurements)

The small vessel (see Fig. 2) was used for the osmotic

treatment of strawberries in those experiments con-

cerning the volume retention. Four hundred grams of

medium-sized strawberry halves were treated in 60%

sucrose solution for 3±22 h at 20°C.

3.4. Microwave-vacuumdrying

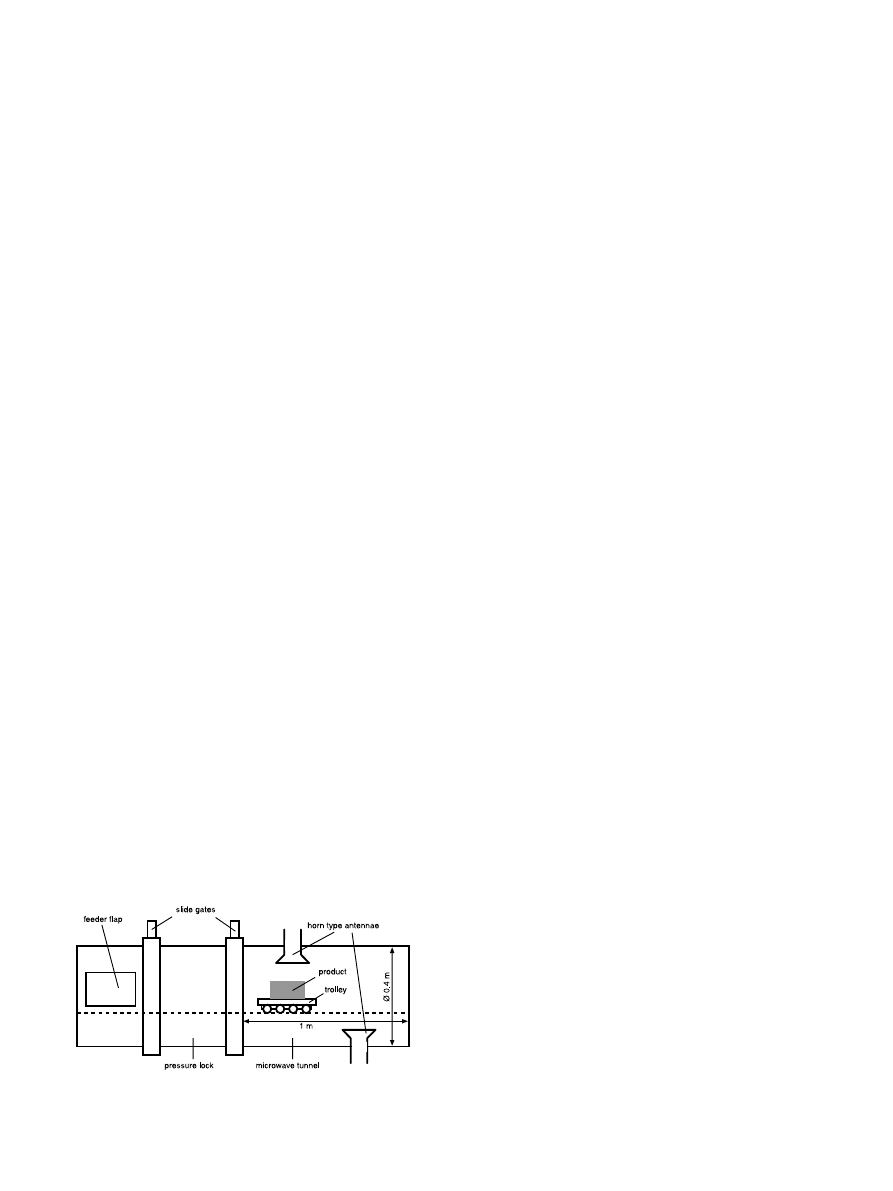

Microwave drying of the fresh and osmotically

treated fruits took place in a pilot-scale microwave

plant, designed to simulate an industrial microwave

tunnel (see Fig. 3). The pieces were put on a tray which

allows the steam to exit in all directions. The trolley goes

back and forth, and the magnetrons are only switched

on when it comes near the corresponding horn antenna,

so the microwaves are used in a pulsed way. Since mi-

crowave power absorption depends mainly on the

amount of water in the samples, the microwave dryer

was always fed with samples containing 140 5 g of

water, regardless of the percentage of water removed in

the osmotic process. This makes the experiments com-

parable. However, one of the results in earlier experi-

ments was that the osmotic pre-treatment made

microwave drying more ecient both in terms of re-

moved water and achieved water activity. The main

reasons for this are higher dielectric losses caused by the

ions and sucrose (Padua, 1993) as well as the better

microwave absorption of less shrunk objects. As a re-

sult, the following microwave programs were applied:

· Strawberries: 390 W for 37 min plus 195 W for 15

min;

· Apples (osmotically treated at 20°C without calcium):

390 W for 30 min plus 195 W for 39 min;

· Apples (osmotically treated at temperatures higher

than 20°C or with calcium): 390 W for 21 min plus

195 W for 13 min;

· Untreated, fresh apple and strawberry pieces needed

longer microwave drying. Water activities lower than

0.5 were achieved in all cases. Pressure was always

5 kPa.

3.5. Measurements of sugar and vitamin C

Frozen samples were homogenized in a laboratory

mixer together with 100 g of ice and 50 ml of 15% meta-

phosphoric acid. The slurry was poured into a ¯ask and

its pH was altered to 3.5±4 by potassium hydroxide. The

¯ask was then ®lled with water up to 500 ml. The con-

tents of the ¯ask were ®ltered and used for the following

measurements.

Fructose, glucose and sucrose were determined by

HPLC. Vitamin C in strawberries was measured by an

enzymic test (Boehringer no. 409 677). As the vitamin

content in the apples used here proved to be rather low,

a dierent method had to be chosen: Vitamin C

(ascorbic acid + dehydroascorbic acid) in fresh, osmoti-

cally treated and microwaved apples was measured by a

chemical method involving titration with dichlorphe-

nolindophenol-sodium. A 1% solution of oxalic acid was

used in the homogenizer to inhibit further degradation

of the vitamin C. After homogenization, the slurry was

®ltered, and the chemical procedure was applied to the

®ltrate.

3.6. Measurements of calcium in apple tissue

Six grams of fresh apple tissue or a smaller amount of

osmotically treated apple tissue (equalling 6 g before

osmotic treatment) from ®ve dierent slices were meshed

and boiled for 2h in a mixture of 21 ml concentrated

HCl and 7 ml concentrated HNO

3

. This mixture was

®ltered, and a 3.5% HNO

3

solution was added up to 100

ml. Calcium content in apple tissue was determined by

Atomic Absorption Spectroscopy (Perkin Elmer 1100 B)

at 422.7 nm.

3.7. Volume measurements

Volume of the fresh and osmotically treated straw-

berries and apples was determined by measuring their

Fig. 3. Microwave pilot plant.

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

195

buoyancy in water, while the volume of dry samples was

found through measuring the displacement of glass

spheres of known bulk density.

4. Results and discussion

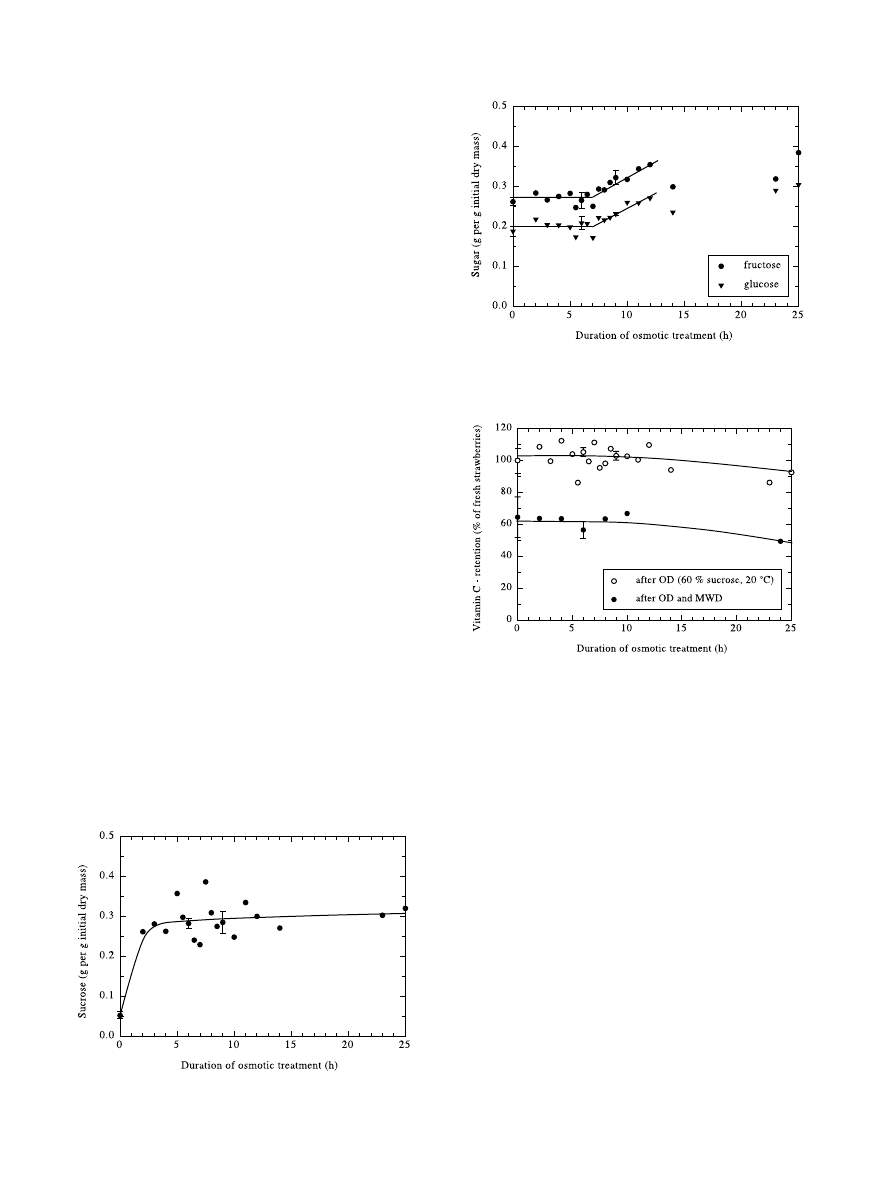

The gain of sucrose during osmotic dehydration of

strawberries is depicted in Fig. 4. The ®rst triple point at

zero hours osmotic treatment ± the samples were just

dipped in the sucrose solution and then washed imme-

diately ± gave a starting point of 5% sucrose based on

the initial dry mass. Most of the following sucrose gain

of approximately 25±30% (initial dry basis) happened

within the ®rst two hours.

The evolution of the fructose and glucose content is

presented in Fig. 5. There was no signi®cant increase of

the two sugars in the ®rst few hours. After approxi-

mately 7 h, an upward trend for both glucose and

fructose started. This was most likely caused by hydro-

lysis of sucrose. Since the sucrose content remained more

or less constant in that period of time, the conclusion is

that the rate of sucrose conversion into glucose and

fructose was the same as the rate of sucrose entering the

tissue. The ¯ow of sucrose seemed to have stopped (see

Fig. 4), but in reality it had not. Models describing os-

motic dehydration should take into account that enzy-

mic reactions may ± after a few hours ± in¯uence the

sugar composition and therefore the whole process.

Preservation of vitamin C is the subject of Fig. 6.

During the osmotic treatment (upper curve) a loss of a

few percent ± comparable to typical losses during storage

at 20°C ± occurred for long durations. After microwave-

vacuum drying with the procedure described earlier,

approximately 60% of the vitamin was still detected, re-

gardless of the duration of osmotic treatment. Single

experiments with more gentle procedures (not reported

here) indicate that preservation of the vitamin can still be

improved, but only at the price of longer drying times.

Fig. 7 shows that the apples exhibited virtually no

loss of vitamin C during osmotic treatment. The ®nal

vitamin C content was around 60% with no obvious

correlation to the duration of the osmotic treatment.

Like for the strawberries, this value is only valid for the

microwave procedure applied here.

The concentration of vitamin C in these apples was

quite low even in the fresh material (25 mg/100 g of

initial dry matter), which is why the enzymic test had to

be replaced by a chemical method. In this particular

case, the retention of the vitamin is not very important

for nutritional reasons, but still serves as an indicator of

thermal damage.

In Fig. 8, the upper curve mainly represents shrinkage

caused by water loss during osmotic dehydration of

strawberries. The lower curve shows how much an os-

motic pre-treatment can in¯uence the volume of the ®nal

product. Strawberries which stayed in the sucrose solu-

tion for 22 h took up a volume higher by a factor of 2.5

compared to those solely microwave-dried. It is appar-

ent that this increase cannot be explained by the volume

Fig. 4. Sucrose uptake of strawberries in 60% sucrose solution at 20°C.

Fig. 5. Evolution of fructose and glucose during osmotic dehydration

of strawberries in 60% sucrose solution at 20°C.

Fig. 6. Vitamin C retention during osmotic and combined drying of

strawberries.

196

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

of the extra sucrose itself. Samples without pre-treat-

ment were also notably softer than those with a long

osmotic step. The latter appeared more crispy and

brittle. It is very likely to be the interaction of the su-

crose with the pectins in the strawberries that has caused

this change in structure and volume.

Apple slices were also treated osmotically under the

same conditions as strawberries. The result ± given in

Fig. 9 ± was very similar to that of the strawberries.

Again, the volume of the pieces after microwave drying

could be increased by a factor of up to 2.5 (lower curve).

Fig. 10 displays how the samples behave at various

durations of osmotic treatment, when temperature is

50°C, and the concentration of calcium chloride is 1%.

The main conclusion from this curve is especially of

practical relevance as it aects the design of industrial

equipment. Under these conditions, it takes approxi-

mately 8 h to reach the maximum eect concerning the

®nal volume. This is much quicker than at 20°C without

calcium (Fig. 9). Then, 15 h were needed for maximum

volume. Another interesting aspect here is that the re-

moval of a great portion of the water takes place even in

the ®rst four hours, but the mechanism responsible for

structure build-up takes twice as long.

Fig. 11 shows the eect of various temperatures on

the volume of the apples at constant calcium chloride

concentration of 1% and constant duration of 6 h. Like

before, the upper curve gives the volume after osmotic

treatment alone, and the lower curve is for the ®nal

volume. The error bars represent the standard deviation

of three measurements. There is a clear trend concerning

the speed of water removal: going to higher tempera-

tures, the upper curve drops, indicating accelerated

water transport. Since enhanced uptake of sucrose and

calcium are also linked to higher temperatures, the

volume of the ®nal product, in which pectins, sucrose

and calcium are assumed to take part in gel formation,

can be increased considerably.

In Fig. 12the concentration of calcium chloride in the

osmotic solution was varied at constant temperature

(50°C) and duration (6 h). As mentioned before, sucrose

concentration was 60% minus calcium chloride con-

Fig. 9. Shrinkage during osmotic and combined drying of apples at

20°C.

Fig. 10. Shrinkage during osmotic and combined drying of apples at

50°C.

Fig. 8. Shrinkage during osmotic and combined drying of strawberries

at 20°C.

Fig. 7. Vitamin C retention during osmotic and combined drying of

apples.

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

197

centration. Since calcium chloride, which replaced the

same amount of sucrose, has a higher osmotic activity

per gram than sucrose, the volume of the samples after

osmosis has a slight downward trend. However, the

volume of the ®nal product could clearly be enhanced by

the calcium. For high concentrations of calcium the

samples even expanded in the microwave drier. This can

be explained by a certain pressure build-up in the tissue

as steam is created rapidly (mainly in the ®rst half of the

drying time). Of course, pressure is also generated in

those samples, which are not pre-treated. The key

question is whether the material is stable enough to

withstand the contracting force that occurs in the ®nal

stages of drying, when the expanding force of the steam

ceases. Obviously, the added calcium renders this extra

stability. The texture of those samples treated with high

concentrations of calcium was especially rigid and brit-

tle; it resembled a freeze dried product.

In an attempt to increase the volume of dried apple

further, the following two osmotic treatments were also

tested: 8 h at 60°C in 60% sucrose and in 54% sucrose

plus 6% calcium chloride, respectively. There was no

additional improvement. The ®nal volume was 59% of

the fresh volume in both cases.

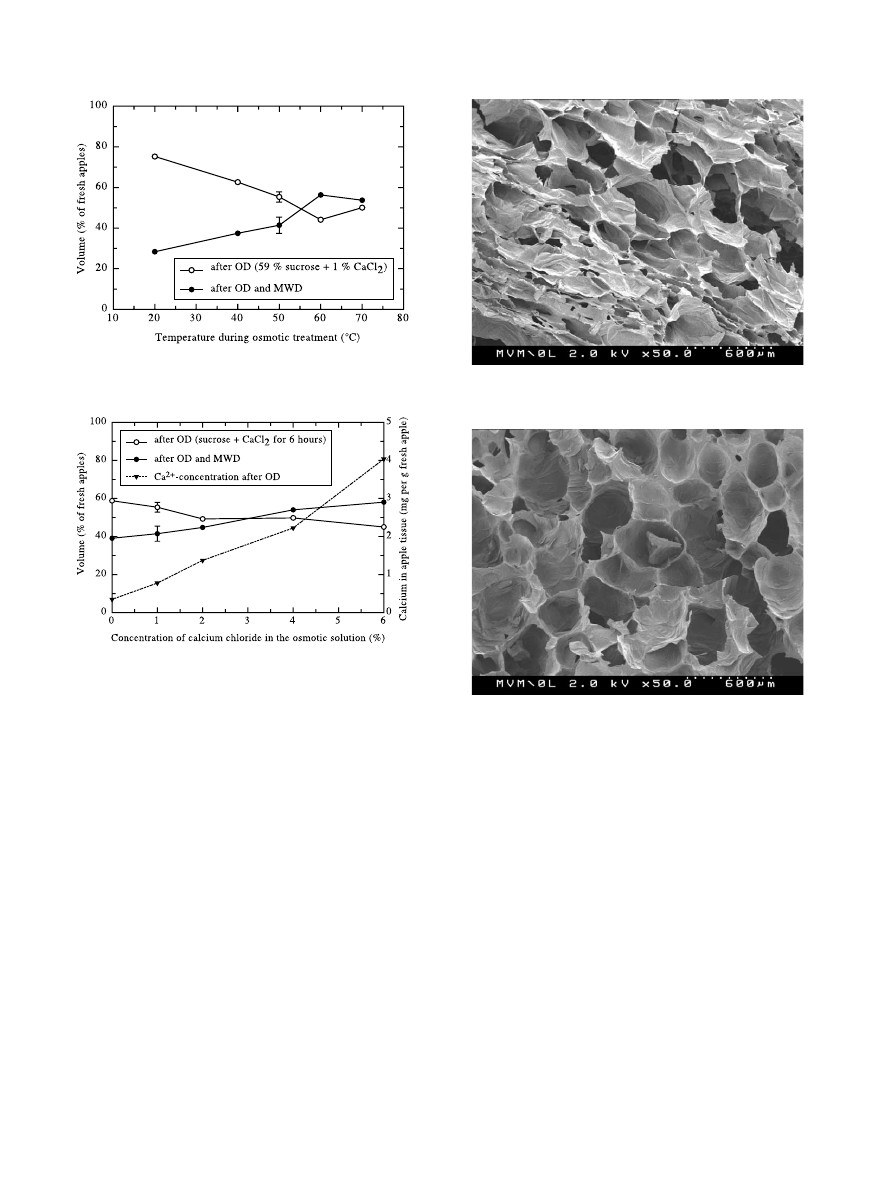

Fig. 13 is an SEM picture of an untreated apple slice

after microwave-vacuum drying. The surface shown was

created by breaking the sample in liquid nitrogen after

drying. For comparison, Fig. 14 demonstrates the better

retention of volume and shape at the cellular level in the

osmotically pre-treated sample (60°C for 6 h with 1%

calcium chloride).

5. Conclusions

Microwave-vacuum drying of osmotically pre-treated

fruits combines the bene®ts of both unit operations.

Selecting the conditions during osmotic treatment oers

the possibility of in¯uencing both the eciency of mi-

crowave dehydration and the properties of the ®nal

product. High-quality products in terms of colour, taste,

Fig. 13. Cell structure of microwave-vacuum dried apple without pre-

treatment.

Fig. 14. Cell structure of microwave-vacuum dried apple with pre-

treatment.

Fig. 11. Shrinkage during osmotic and combined drying of apples for

6 h.

Fig. 12. Shrinkage during osmotic and combined drying of apples at

50°C.

198

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

vitamin C content, structure and volume can be ob-

tained. Vitamin C retention was around 60% for apples

and strawberries with the microwave program used in

this study. In the combined process, volume was pre-

served by up to 60% of the fresh apples and up to 50% of

the fresh strawberries, respectively.

Acknowledgements

The authors wish to thank the Max-Buchner-For-

schungsstiftung for the support of this research.

References

Barbosa-Canovas, G. V., & Vega-Mercado, H. (1996). Dehydration of

foods. New York: Chapman and Hall.

Buer, C. R. (1993). Microwave cooking and processing: engineering

fundamentals for the food scientist. New York: Van Nostrand

Reinhold.

Glenn, G. M., & Poovaiah, B. W. (1990). Calcium mediated

postharvest changes in texture and cell wall structure and compo-

sition in `Golden Delicious' apples. Journal American Society of

Horticulture Science, 115(6), 962±968.

Gunasekaran, S. (1999). Pulsed microwave-vacuum drying of food

materials. Drying Technology, 17(3), 395±412.

Isse, M.G., Schubert, H. (1995). Dissolved starch as an osmotic

dehydrating agent of fruit and vegetables. In F. Meuser, D. J.

Manners, & W. Seibel, (Eds.), Progress in plant polymeric carbo-

hydrate research. Hamburg: Behr`s Verlag.

Padua, G. W. (1993). Microwave-heating of agar gels containing

sucrose. Journal of Food Science, 58(6), 1426±1428.

Pilnik, W. (1980). Pektine und Alginate. In Gelier- und Verdickung-

smittel in Lebensmitteln (Gelling and thickening agents in foods).

Zurich, Switzerland: Forster Verlag AG.

Roussy, G., & Pearce, J. A. (1995). Foundations and industrial

applications of microwaves and radio frequency ®elds. Great Britain:

Wiley.

U. Erle, H. Schubert / Journal of Food Engineering 49 (2001) 193±199

199

Wyszukiwarka

Podobne podstrony:

więcej podobnych podstron